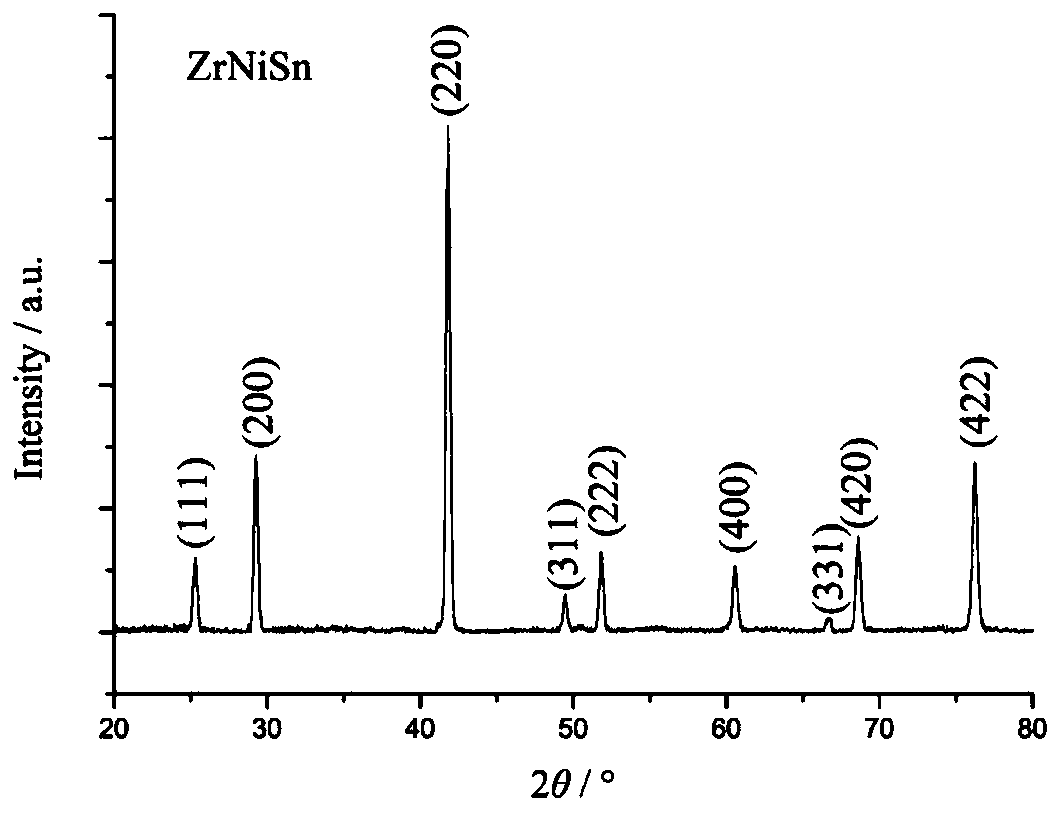

Method for rapidly preparing ZrNiSn thermoelectric material

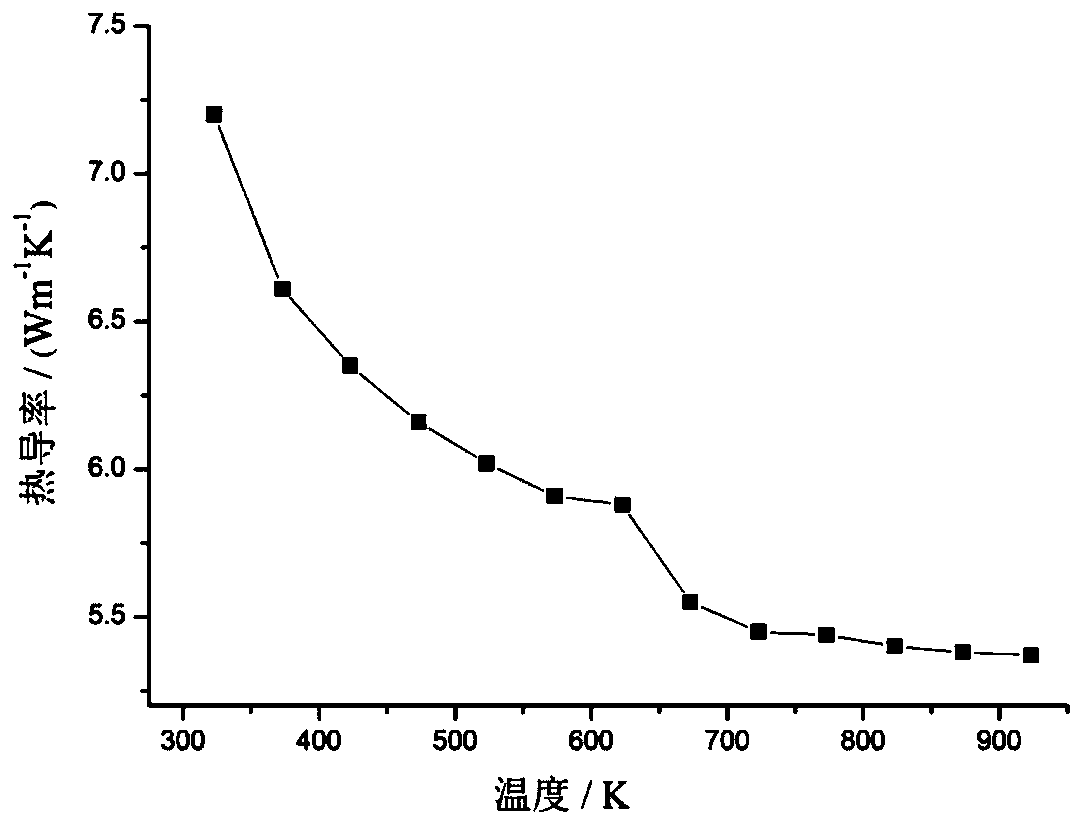

A thermoelectric material and fast technology, which can be applied in the direction of thermoelectric device node lead-out material, etc., can solve the problems of increasing energy consumption, reducing lattice thermal conductivity, nano-grain growth, etc., achieving short synthesis cycle and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

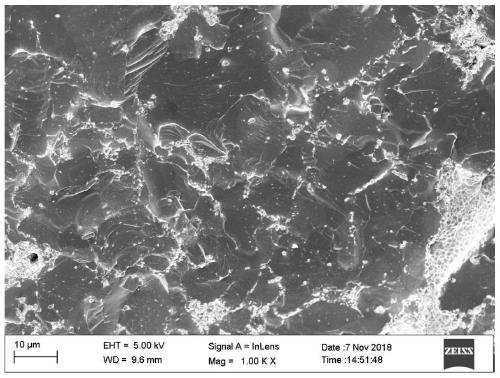

Embodiment 1

[0036] According to the stoichiometric molar ratio of 1:1:1, Zr powder, Ni powder and Sn powder with a purity greater than 99.9% were weighed, mixed evenly, and then cold-pressed into a columnar body with a uniaxial pressure of 5 MPa and a holding time of 15 minutes to obtain a diameter of 40 mm. , 20mm high columnar green body;

[0037] Place the cold-pressed green body in a quartz mold, place the mold at one end of the centrifuge in a steel reaction chamber, place a tungsten coil as an ignition medium on the upper surface of the green body, and pump the reaction chamber to a vacuum of 10 -3 Pa;

[0038] Turn on the high-speed rotation of the centrifuge, set the gravity field to 1500G, and burn the tungsten wire spring coil under the supergravity field to ignite the green body to produce a combustion synthesis reaction;

[0039] After the reaction is over, continue to apply the supergravity field for 10 minutes;

[0040] The supergravity field was removed, and the sample wa...

Embodiment 2

[0048] Weigh Zr powder, Ni powder and Sn powder with a purity greater than 99.9% according to the stoichiometric molar ratio of 1:1:1, mix them evenly, and cold press them into a columnar green body. The uniaxial pressure is 8 MPa, and the holding time is 12 minutes to obtain a diameter of 40 mm. , 20mm high columnar green body;

[0049] Place the cold-pressed green body in a quartz mold, place the mold at one end of the centrifuge in a steel reaction chamber, place a tungsten coil as an ignition medium on the upper surface of the green body, and pump the reaction chamber to a vacuum of 10 -4 Pa;

[0050] Turn on the high-speed rotation of the centrifuge, set the gravity field to 1200G, and burn the tungsten wire spring coil under the supergravity field to ignite the green body to produce a combustion synthesis reaction;

[0051] After the reaction is over, continue to apply the supergravity field for 15 minutes;

[0052] The supergravity field was removed, and the sample wa...

Embodiment 3

[0056] Weigh Zr powder, Ni powder and Sn powder with a purity greater than 99.9% according to the stoichiometric molar ratio of 1:1:1, mix them evenly, and cold press them into a columnar green body with a uniaxial pressure of 10 MPa and a holding time of 8 minutes to obtain a diameter of 40 mm. , 20mm high columnar green body;

[0057] Place the cold-pressed green body in a quartz mold, place the mold at one end of the centrifuge in the steel reaction chamber, place a tungsten coil as an ignition medium on the upper surface of the green body, and vacuum the reaction chamber and fill it with inert Gas to 5Pa;

[0058] Turn on the high-speed rotation of the centrifuge, set the gravity field to 1000G, and burn the tungsten wire spring coil under the supergravity field to ignite the green body to produce a combustion synthesis reaction;

[0059] After the reaction, continue to apply the supergravity field for 10 minutes.

[0060] The supergravity field was removed, and the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| thermoelectricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com