Novel low-thermal-conductivity argyrodite thermoelectric material and preparation method thereof

A technology of thermoelectric material and silver-germanium ore, which is applied in the direction of lead-out wire material of thermoelectric device and the manufacture/processing of thermoelectric device, which can solve the problems of low mechanical strength and easy breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

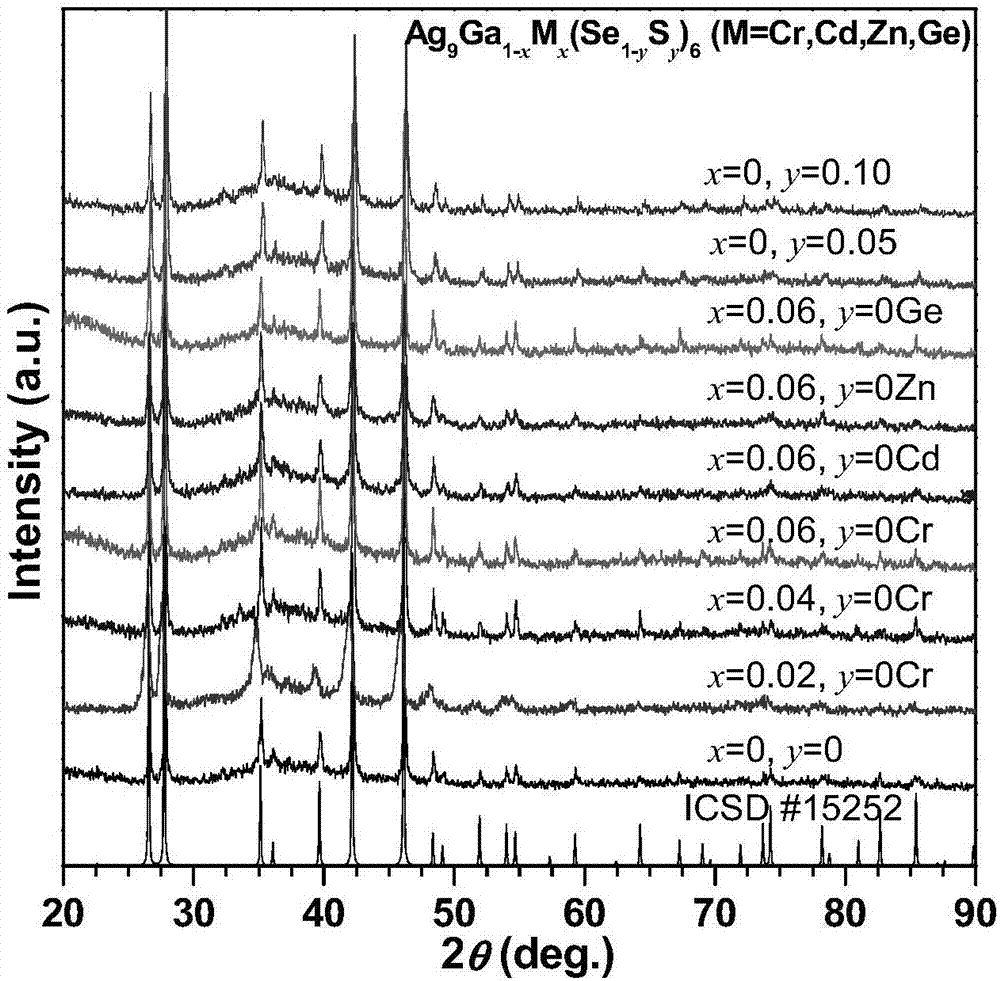

[0037] A new type of thermoelectric material whose chemical formula is Ag 9 GaSe 6 , according to the following preparation method, to obtain Ag 9 GaSe 6 Block material:

[0038] (1) Use simple substances with a purity greater than 99.99% as raw materials, weigh the ingredients according to the stoichiometric ratio, and place them in a sealed quartz tube for vacuum packaging;

[0039] (2) Heating with a muffle furnace, heating the quartz tube from room temperature to 1223K, melting and reacting the high-purity raw material at a high temperature, and keeping the temperature for 6 hours, then rapidly quenching and cooling to obtain the first ingot;

[0040] (3) Heating with a muffle furnace, heating the quartz tube from room temperature to 900K, performing annealing treatment, and after 3 days of heat preservation, rapid quenching and cooling to obtain the second ingot;

[0041] (4) Grind the second ingot into powder, place it in a graphite mold, heat it up to 900K at a rate...

Embodiment 2

[0043] This example is basically the same as Implementation 1, the difference is that in this implementation, the chemical formula is Ag 9 Ga 0.98 Cr 0.02 Se 6 .

Embodiment 3

[0045] This example is basically the same as Implementation 1, the difference is that in this implementation, the chemical formula is Ag 9 Ga 0.96 Cr 0.04 Se 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com