Method for reducing thermal conductivity of bismuth telluride polycrystal lattice

A bismuth telluride, thermal conductivity technology, applied in chemical instruments and methods, polycrystalline material growth, binary selenium/tellurium compounds, etc. Lattice thermal conductivity and other issues, to achieve the effect of strong operability, reduced lattice thermal conductivity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the content described.

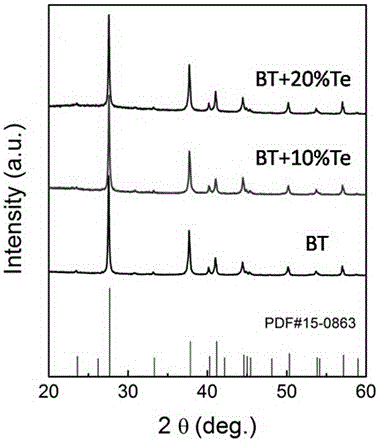

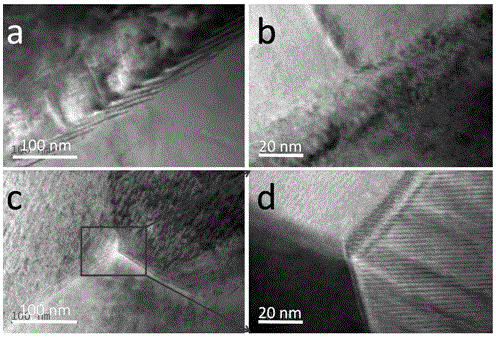

[0019] The bismuth telluride powder was prepared by mechanical alloying, the ball milling speed was 100~400 rpm, the time was 2~12 h, the ball-to-material ratio was 1:10, the ball milling medium was glycerol, and the ball milling speed was 100~400 rpm. -12 hours, then the mixed powder was centrifugally cleaned with absolute ethanol, and then vacuum-dried at 80°C for 12 hours, and the obtained dry powder was manually ground for later use; the bismuth telluride prepared above The powder is mixed with elemental tellurium with an additional mass ratio of 5%~30%, and then ground to obtain a mixed powder. The mixed powder is placed in a graphite mold, and the tellurium is prepared by sintering at 450~580°C for 0~30 minutes using a spark plasma sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com