Environment-friendly sulfur group stannide thermoelectric material and preparing method thereof

An environment-friendly, thermoelectric material technology, applied in the field of chalcogentin compound thermoelectric materials and its preparation, to achieve high thermoelectric performance, improve thermoelectric performance, and reduce the effect of lattice thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

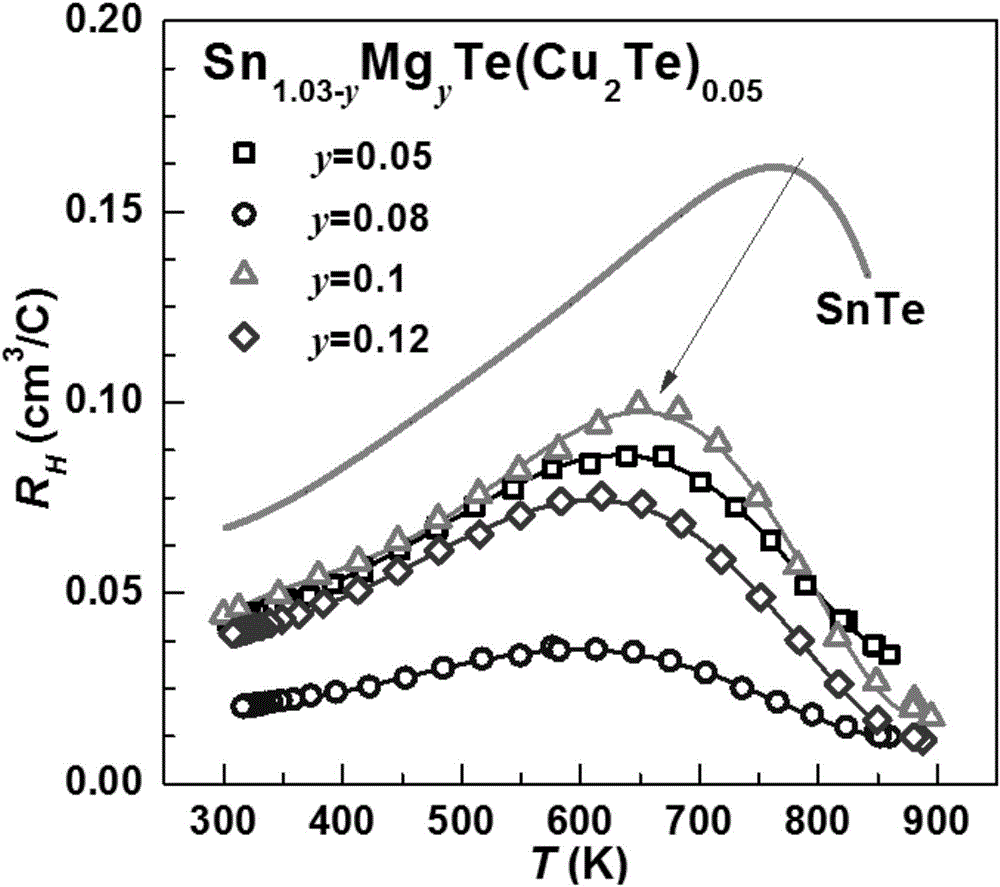

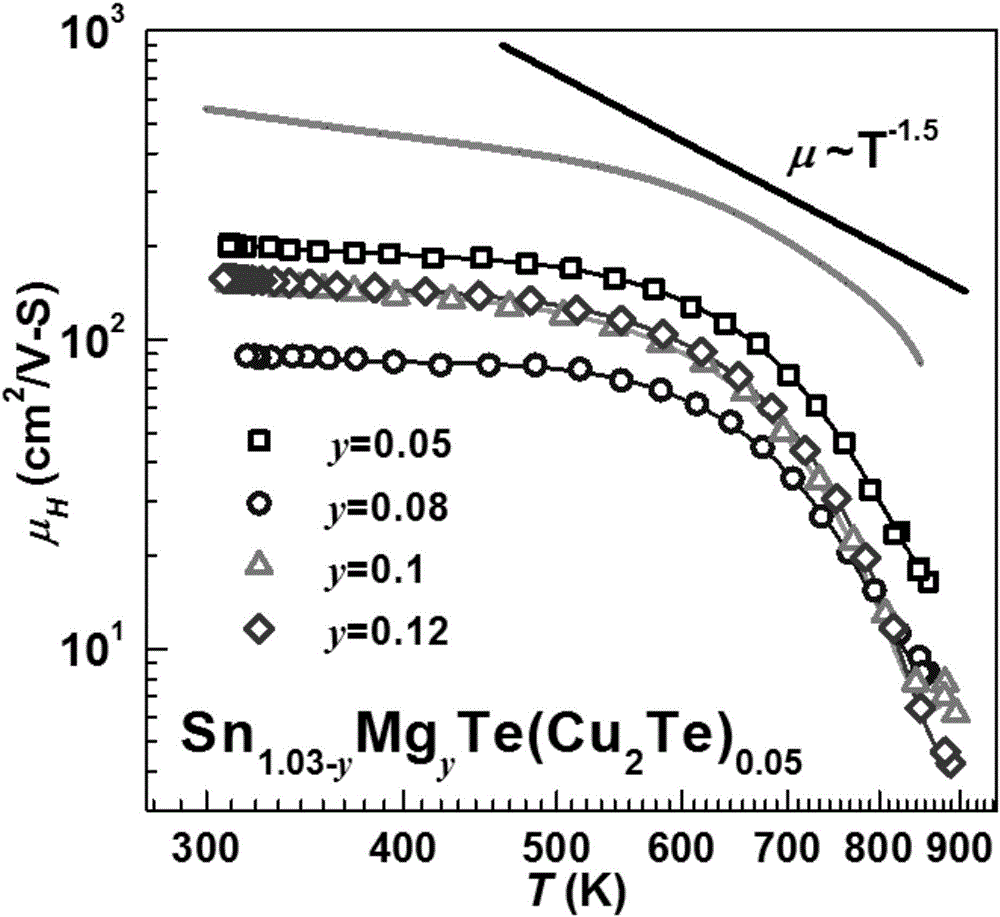

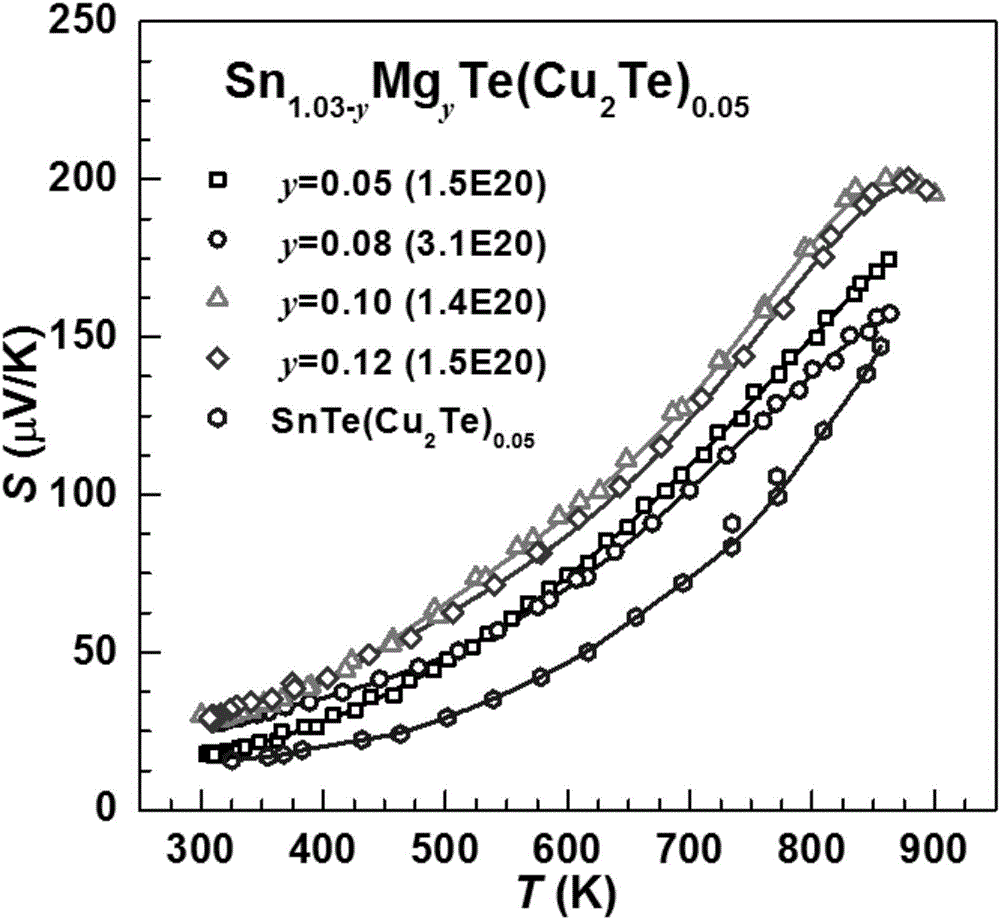

[0034] A high-performance and environment-friendly chalcogenide tin compound thermoelectric material with the chemical formula Sn 1.03-y Mg y Te(Cu 2 Te) x (01.03-y Mg y Te(Cu 2 Te) 0.05 Block material:

[0035] (1) Take different y values, according to the chemical formula Sn 1.03-y Mg y Te(Cu 2 Te) 0.05 Stoichiometric ratio of (0<y≤0.12) Weigh elemental raw materials tin Sn, magnesium Mg, copper Cu, tellurium Te with a purity greater than 99.99%, place the raw materials in a quartz tube, and seal the quartz tube under vacuum.

[0036] (2) Suspend the quartz tube containing the raw material in the pit furnace, slowly raise the temperature to 850°C at a rate of 200K / h, keep it warm for 6h, and then rapidly quench and cool to obtain the first ingot;

[0037] (3) heat-treating the first ingot after high-temperature melting and quenching obtained in step (2), slowly raising the temperature to 677°C at a rate of 200K / h, keeping it warm for 3 days, and then rapidly quench...

Embodiment 2

[0045] An environment-friendly chalcogentin compound thermoelectric material with the chemical formula Sn 1.03-y Mg y Te(Cu 2 Te) x (x=0.03, y=0.05), which is a semiconductor thermoelectric material.

[0046] A method for preparing an environment-friendly chalcogentin compound thermoelectric material, comprising the following steps:

[0047] (1) Vacuum packaging: use the elemental elements Sn, Mg, Cu, Te with a purity greater than 99.99% according to the chemical formula Sn 1.03-y Mg y Te(Cu 2 Te) x The stoichiometric ratio in (x=0.03, y=0.05) is batched, and vacuum-packed in a quartz tube;

[0048] (2) Melting and quenching: Put the quartz tube with raw materials into the well-type furnace, raise the temperature of the quartz tube from room temperature to 850 °C at a rate of 150 °C per hour and keep it warm for 6 hours, and heat slowly to make the raw material in a molten state Fully reacted, followed by quenching to obtain ingots;

[0049] (3) Annealing and quenchin...

Embodiment 3

[0053] An environment-friendly chalcogentin compound thermoelectric material with the chemical formula Sn 1.03-y Mg y Te(Cu 2 Te) x (x=0.05, y=0.12), which is a semiconductor thermoelectric material.

[0054] A method for preparing an environment-friendly chalcogentin compound thermoelectric material, comprising the following steps:

[0055] (1) Vacuum packaging: use the elemental elements Sn, Mg, Cu, Te with a purity greater than 99.99% according to the chemical formula Sn 1.03-y Mg y Te(Cu 2 Te) x The stoichiometric ratio in (x=0.05, y=0.12) is batched, and vacuum-packed in a quartz tube;

[0056] (2) Melting and quenching: Put the quartz tube with raw materials into the well-type furnace, raise the temperature of the quartz tube from room temperature to 900 °C at a rate of 200 °C per hour and keep it warm for 6 hours, and heat slowly to make the raw material in a molten state Fully reacted, followed by quenching to obtain ingots;

[0057] (3) Annealing and quenchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com