Adulterated titanium-cobalt-stibium based thermoelectric composite material, and preparation method

A composite material, a titanium-cobalt-antimony-based technology, applied in the field of doped titanium-cobalt-antimony-based thermoelectric composite materials and its preparation, can solve the problems of unsuitability for large-scale industrial production, lower lattice thermal conductivity, and long preparation cycle , to achieve good electrical transmission performance, reduce lattice thermal conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Ti 1.12 CoSb composite

[0023] Using the method mentioned in the summary of the invention, high-purity Ti, Co, and Sb are used as raw materials, and the ingredients are mixed in a molar ratio of 1.12:1:1, mixed evenly, pressed into sheets, and put into an electric arc melting furnace. After vacuuming, fill it with argon for the first smelting, and the smelting time lasts for 1 minute and 30 seconds. After cooling, evacuate, then fill with oxygen, the filling amount is 50% of the excess Ti moles, and then fill with argon to carry out the second smelting. In the second smelting, the working current was continuously adjusted and the sample was turned over and smelted 4 times repeatedly. Repeat the previous step, the charge of oxygen is 48% of the excess Ti moles.

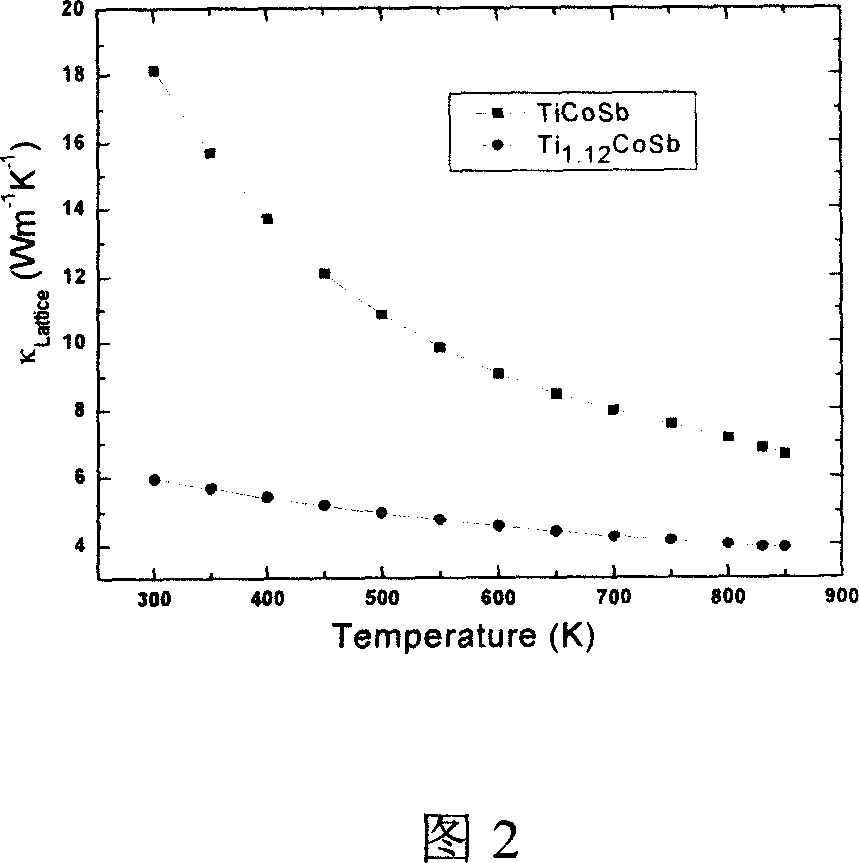

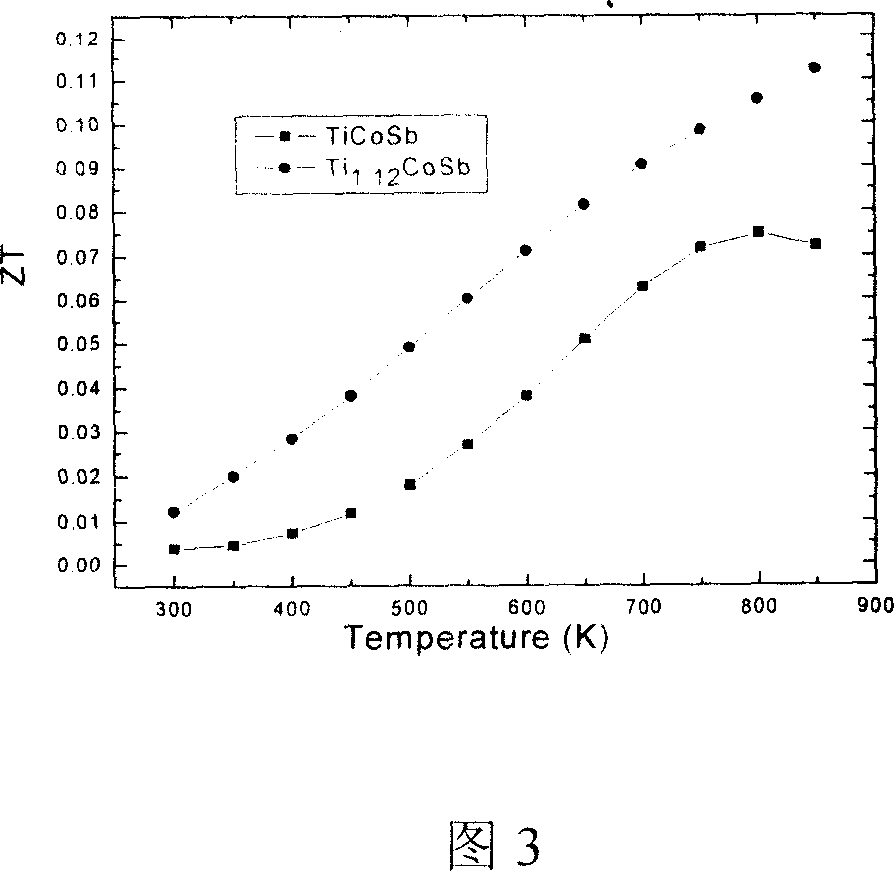

[0024] TEM analysis confirmed the presence of abundant nanoscale TiO in the matrix 2 particles (see Figure 1). These nano-TiO 2 The particles greatly reduce the lattice thermal conductivity of ...

Embodiment 2

[0025] Example 2: Ti 1.09 co 0.85 Fe 0.15 Sb composite material

[0026] Using the method mentioned in the summary of the invention, high-purity Ti, Co, Sb and Fe are used as raw materials, and the ingredients are mixed in a molar ratio of 1.09:0.85:1:0.15. After mixing evenly, they are pressed into sheets and put into an electric arc melting furnace. After evacuating, fill it with argon for the first melting, and the melting time lasts for 40 seconds. After cooling, vacuumize, then fill with oxygen, the filling amount is 40% of the excess Ti moles, and then fill with argon to carry out the second smelting. In the second smelting, the working current was continuously adjusted and the sample was turned over and smelted 4 times repeatedly. Repeat the previous step twice, the amount of oxygen charged is respectively 35% and 20% of the excess Ti moles, and finally the sample is cut into a standard shape for testing. The lattice thermal conductivity and ZT value of the materia...

Embodiment 3

[0027] Example 3: Ti 1.06 co 0.92 Ni 0.08 Sb composite material

[0028]The metal raw materials Ti, Co, Sb and Ni are batched according to the molar ratio of 1.06:0.92:1:0.08, mixed uniformly, pressed into sheets, and put into an electric arc melting furnace. After evacuating, fill with argon for the first smelting, and the smelting time lasts for 4 minutes. After cooling, evacuate, then fill with oxygen, the filling amount is 95% of the excess Ti moles, and then fill with argon to carry out the second smelting. In the second smelting, the working current was continuously adjusted and the sample was turned over and smelted 5 times repeatedly. Tested Ti 1.06 co 0.92 Ni 0.08 The lattice thermal conductivity of Sb is higher than that of TiCo 0.92 Ni 0.08 Sb is reduced by 1 / 3, and the maximum ZT value reaches 0.38 at 850K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com