Mg-Si-Sn-based nano-composite thermoelectric material and preparation method thereof

A mg-si-sn, nano-composite technology, applied in the field of Mg-Si-Sn-based nano-composite thermoelectric materials and its preparation, to achieve the effect of reducing lattice thermal conductivity, improving electrical conductivity and power factor, and reducing interface pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

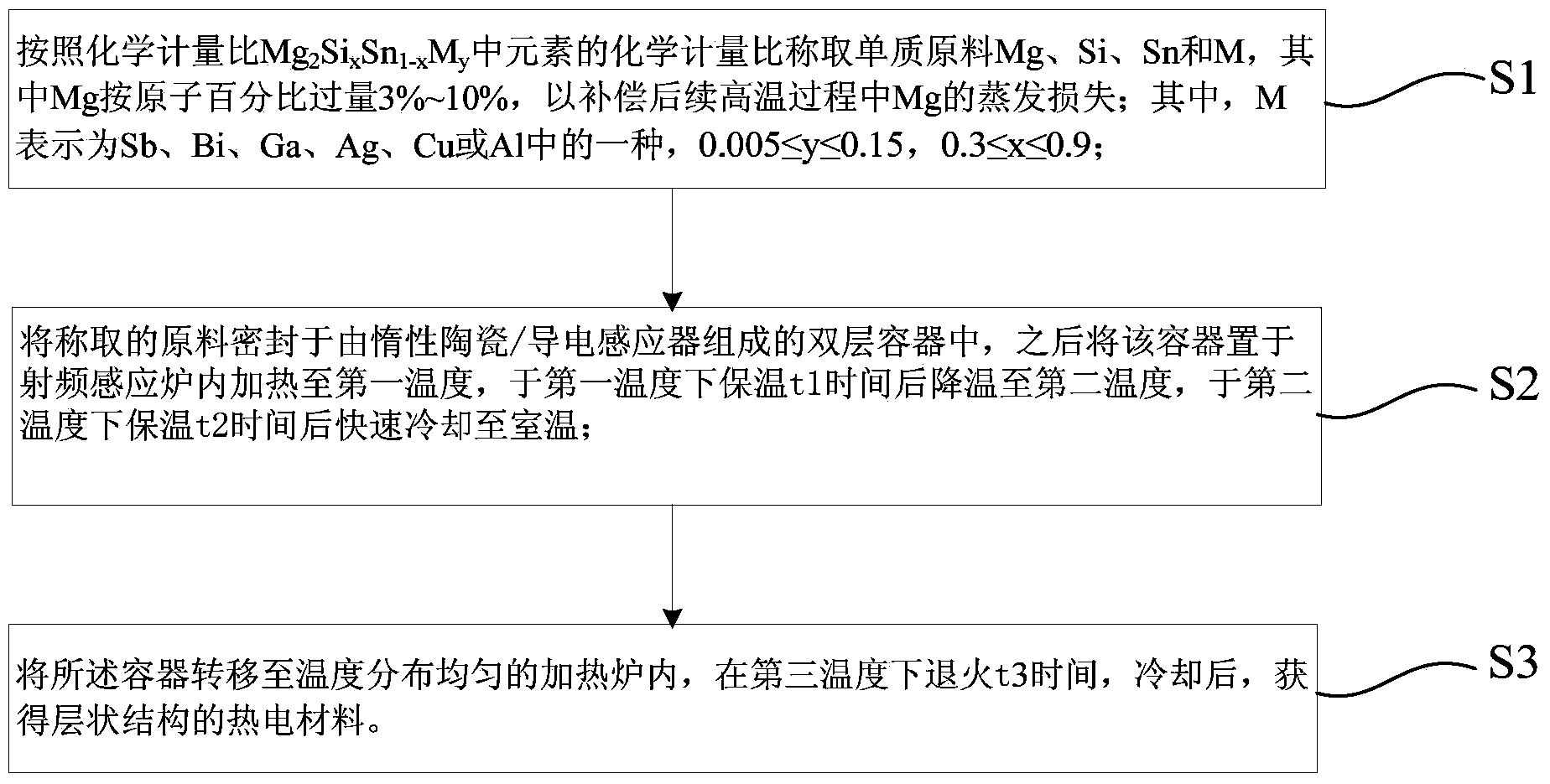

[0047] In the present invention, the process flow of preparing Mg-Si-Sn-based nanocomposite thermoelectric material by using a radio frequency induction furnace medium-speed cooling method and a heat treatment method, such as figure 1 As shown, the preparation method at least includes the following steps:

[0048] Step S1, according to the general chemical formula Mg 2 Si x Sn 1-x M y The stoichiometric ratio of the middle elements is weighed into the elemental raw materials Mg, Si, Sn and M, where the Mg excess is 3%-10% by atomic percentage to compensate for the evaporation loss of Mg in the subsequent high temperature process; where M is represented by Sb, Bi, One of Ga, Ag, Cu or Al, 0.3≤x≤0.9, 0.005≤y≤0.15;

[0049] Step S2, the weighed raw materials are sealed in a double-layer container composed of inert ceramics / conductive inductors, and then the container is placed in a radio frequency induction furnace to be heated to a first temperature, kept at the first temperature for...

Embodiment 1

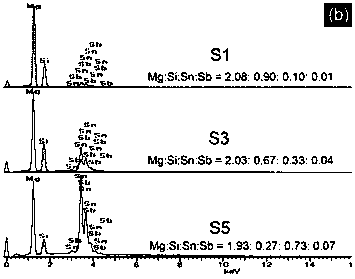

[0056] In a glove box filled with nitrogen, the stoichiometric ratio of Mg 2.10 Si 0.3 Sn 0.7 Sb 0.03 Weigh the elemental raw materials Mg, Si, Sn, and Sb, and seal these raw materials in a double-layer container composed of inert ceramics / conductive inductors, and then place them in a radio frequency induction furnace, and heat to 1000°C under the protection of high-purity nitrogen. Keep it for 30 minutes to fully melt, and then cool down to 600℃ at a rate of 20℃ / min. After keeping it for 30 minutes, it will be quickly cooled to room temperature, and then transferred to a heating furnace with uniform temperature distribution and annealed at 600℃ under the protection of high-purity nitrogen. After hours, cooling at a rate of 5K / min, a Mg-Si-Sn-based thermoelectric material with a layered modulated doped structure and a coherent nanostructure is obtained.

[0057] After obtaining the required thermoelectric material, the morphology analysis and performance test of the material are ...

Embodiment 2

[0064] In a glove box filled with nitrogen, the stoichiometric ratio of Mg 2.10 Si 0.3 Sn 0.7 Bi 0.015 Weigh the elemental Mg, Si, Sn, and Bi raw materials, seal these raw materials in a double-layer container composed of inert ceramics / conductive inductors, and then place them in a radio frequency induction furnace, and heat to 1000°C under the protection of high-purity argon. Keep it for 35 minutes to fully melt, then cool down to 600°C at a rate of 20°C / min, quickly cool to room temperature after holding for 30 minutes, and then transfer to a heating furnace with uniform temperature distribution and anneal at 600°C under the protection of high-purity argon After 40 hours of cooling at a rate of 5K / min, an Mg-Si-Sn-based thermoelectric material with a layered modulated doped structure and a coherent nanostructure is obtained.

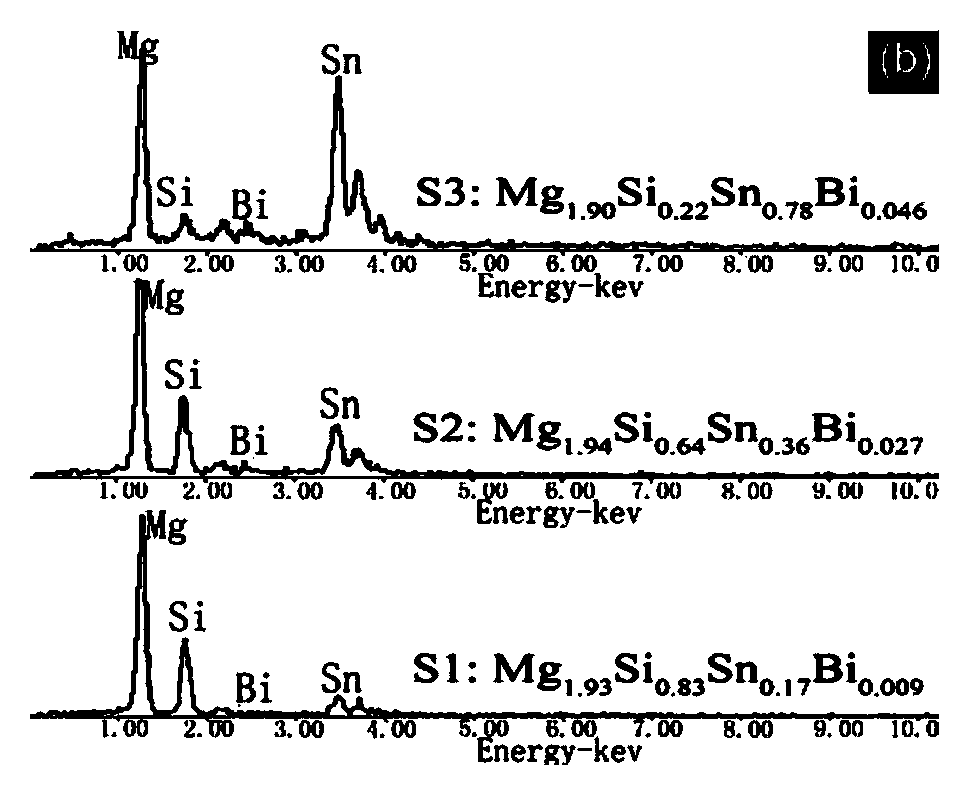

[0065] After obtaining the required thermoelectric material, the morphology analysis and performance test of the material are carried out.

[0066] XRD an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com