High-performance silver-tellurium compound thermoelectric semiconductor material and preparation method thereof

A technology of thermoelectric semiconductors and tellurium compounds, which is applied in the fields of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve problems such as difficulty in thermoelectric performance, and achieve the effect of high thermoelectric performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a high-performance silver-tellurium compound thermoelectric semiconductor material preferably includes the following steps:

[0044] (1) Vacuum packaging: the elemental elements Ag and Te are vacuum packaged in a quartz tube according to the stoichiometric ratio;

[0045] (2) Melting quenching: putting the quartz tube with the raw material in step (1) into a pit furnace for heating, so that the raw material is melted and fully reacted, and then quenched to obtain the first ingot;

[0046] (3) Annealing and quenching: the first ingot obtained in step (2) is re-vacuum-encapsulated in a quartz tube, then placed in a pit furnace for heating, annealed at a high temperature, and then quenched to obtain a second ingot;

[0047] (4) Hot-press sintering: Grind the second ingot obtained in step (3) into powder, then place it in a graphite mold, carry out vacuum hot-press sintering, and then lower the temperature to obtain a sheet-like bulk material, which i...

Embodiment 1

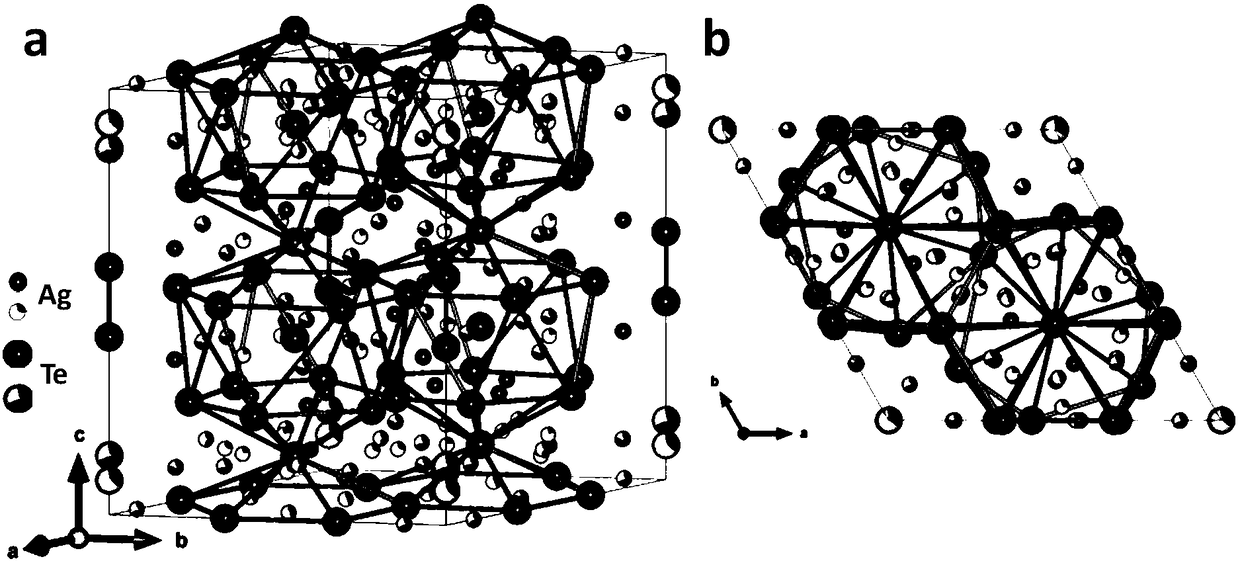

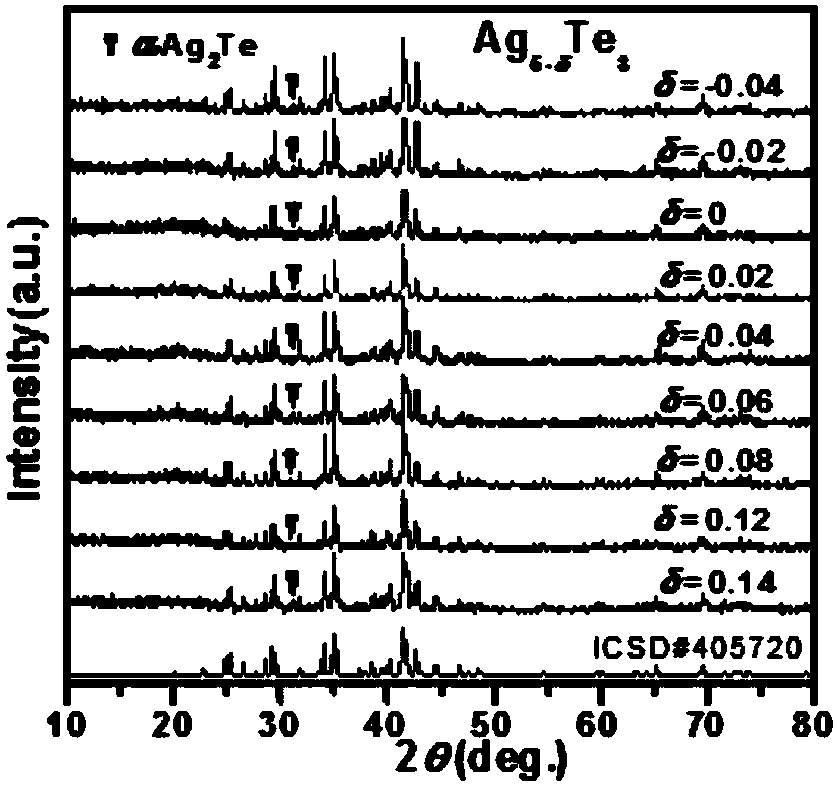

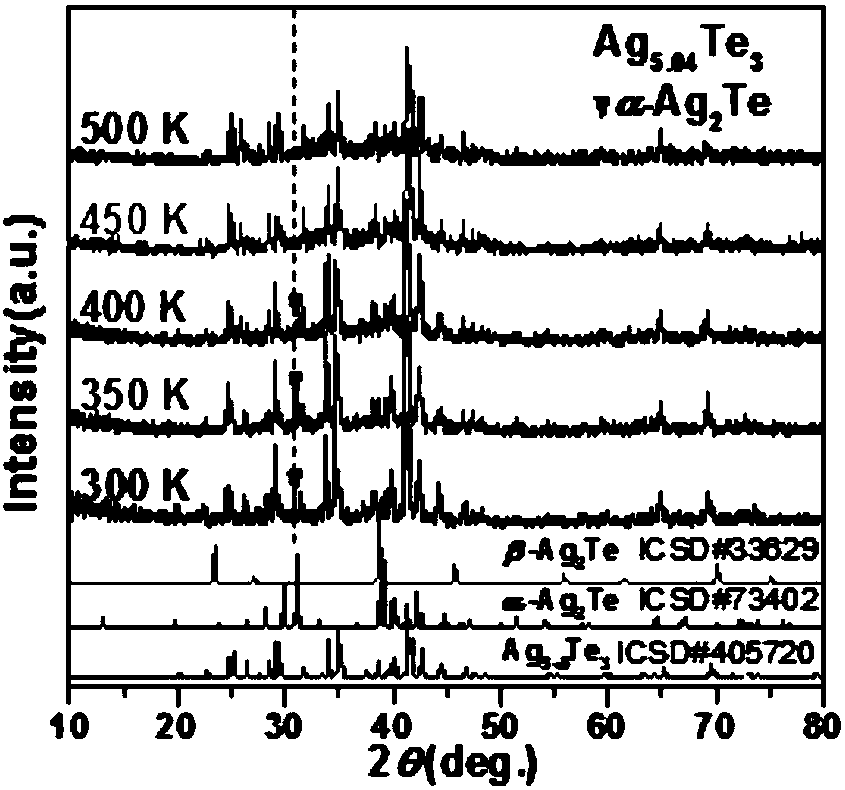

[0055] A kind of silver telluride thermoelectric material, its chemical formula is Ag 5-x Te 3 , x=-0.04~0.14, in the present embodiment by getting x=-0.04,-0.02, 0, 0.02, 0.08 and 0.12 (when x=0, the chemical formula is Ag 5 Te 3 , when x=-0.04, -0.02, 0.02, 0.08 and 0.12, that is, by changing different concentrations of Ag to optimize the composition of the second phase and the matrix phase), according to the following preparation methods, different second items and matrix phases are obtained Composition Ratio of Ag 5-x Te 3 Block material:

[0056] (1) According to different values of x, the chemical formula is Ag 5-x Te 3 The stoichiometric ratio of (x=-0.04~0.14) weighs the elemental raw materials silver Ag and tellurium Te with a purity greater than 99.99%, places the raw materials in a quartz tube, and seals the quartz tube under vacuum.

[0057] (2) Hang the quartz tube containing the raw materials in a high-temperature well-type furnace, slowly raise the temp...

Embodiment 2

[0067] Compared with Example 1, except that x takes a value of 0.14 in this example, all the others are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com