Three-dimensional net-shaped high thermal conductivity graphite framework structure and manufacture method thereof

A high thermal conductivity graphite, three-dimensional mesh technology, applied in the direction of cooling/ventilation/heating transformation, to achieve the effect of strong mechanical strength, improved thermal conductivity, high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

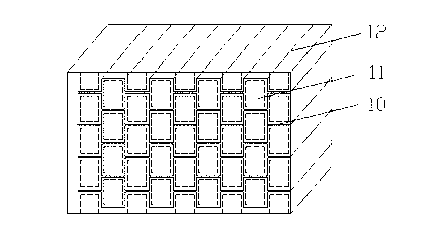

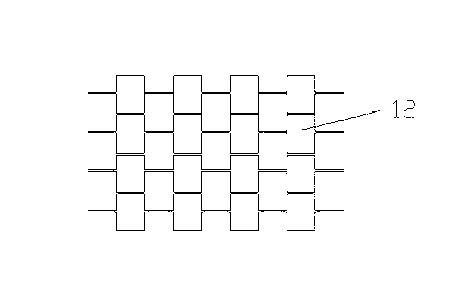

[0022] figure 1 As shown, a three-dimensional net-like high thermal conductivity graphite skeleton structure filled with polymers. It is composed of ten layers of graphite heat conduction film 12, and the connection points between the two adjacent layers of graphite heat conduction films are 9, and the distance between the connection points is greater than 1mm; the thermal conductivity of graphite heat conduction film is 400-2400 W / mK; thickness between 5-1000 μm. In this embodiment, two adjacent layers of graphite heat conduction films (12) are filled with polyester polymer composition (13).

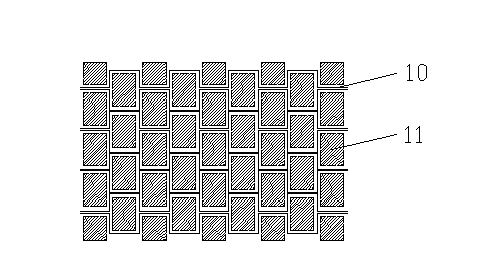

[0023] Such as figure 2 Shown is a schematic diagram of the polymer film 10 used to make the graphite heat-conducting film in the present invention. The graphite film 12 is obtained by stacking and high-temperature graphitization of multilayer polymer films 10, and the polymer film 10 includes at least one polymer selected from the following: polyester, polycarbonate, polyurethane,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com