Novel Zintl phase thermoelectric material and preparation method thereof

A technology of thermoelectric materials and phase thermoelectricity, applied in the field of thermoelectric materials, can solve the problems of low thermal-electric conversion efficiency, achieve the effect of reducing lattice thermal conductivity and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

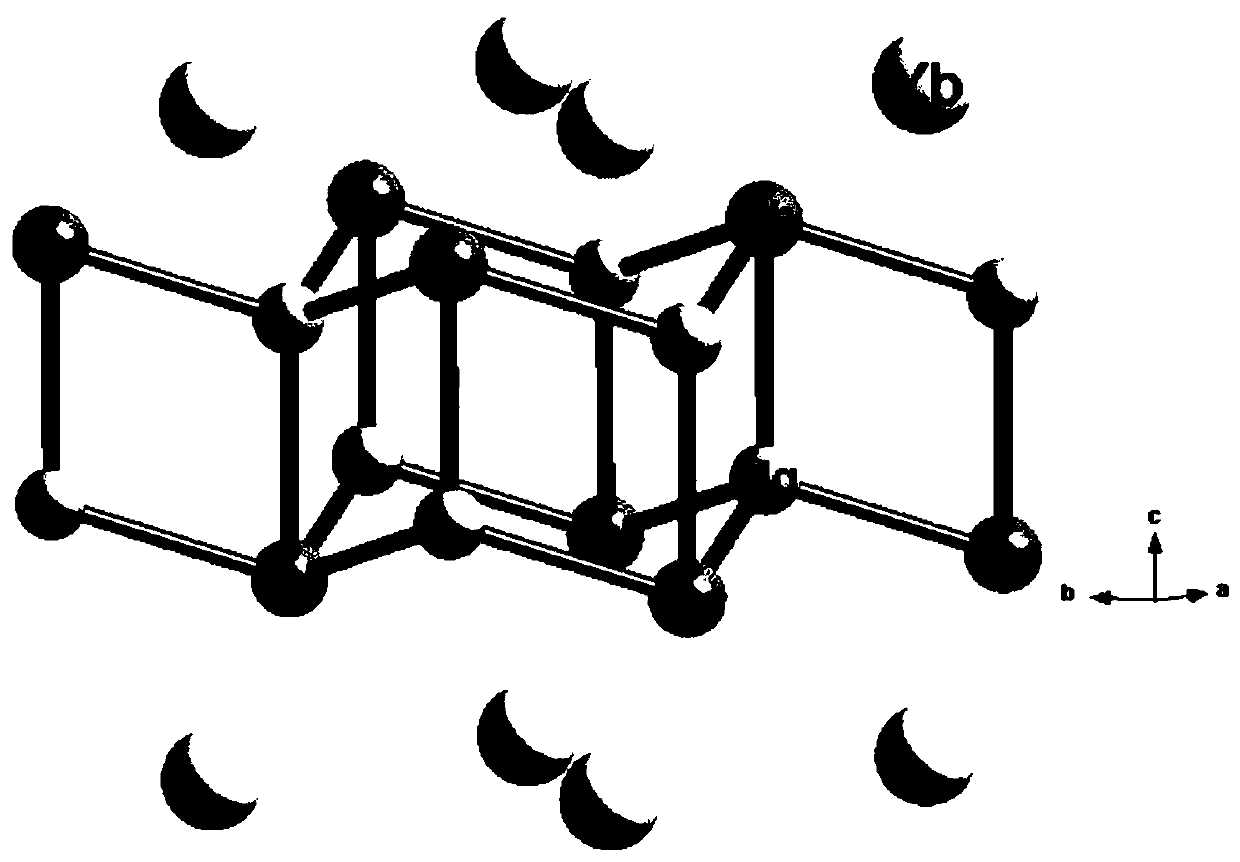

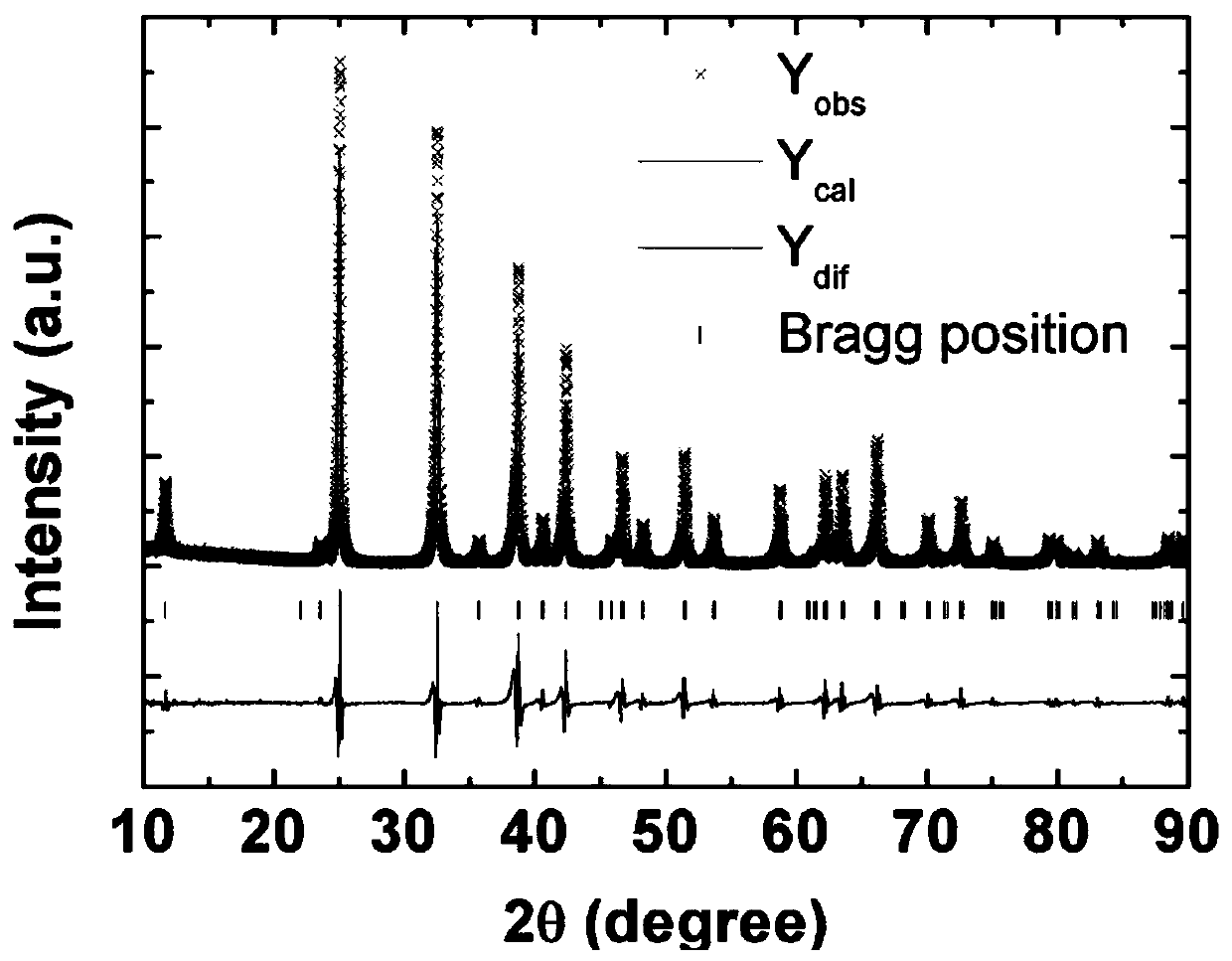

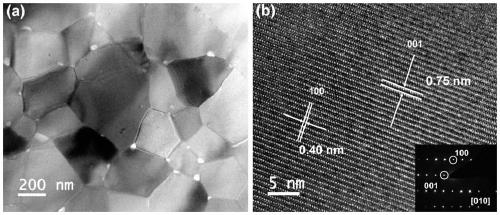

[0030]In this embodiment, a novel Zintl phase thermoelectric material, its chemical formula is YbMg 2 Sb 2 , characterized in that it includes the following steps:

[0031] a. Use Yb, Mg and Sb as raw materials in a glove box in an argon atmosphere environment, according to the target product chemical formula YbMg 2 Sb 2 The composition ratio of 1:2:2 weighs each component and puts it into a ball mill jar equipped with grinding balls and seals it;

[0032] b. Put the ball mill jar in the above step a into a high-energy ball mill for alloying for 2-12 hours to obtain powder for later use;

[0033] c. Put the alloyed powder of the above step b into a graphite mold and hot press and sinter to 99% or more of the theoretical density to obtain the desired thermoelectric material YbMg 2 Sb 2 , the sintering temperature rises from room temperature to 400-800°C, the heating rate is 100°C / min, the sintering holding time is 1-10min, and the sintering pressure is 80MPa.

[0034] Exp...

Embodiment 2

[0038] In this implementation, it is basically the same as Embodiment 1, and the special features are:

[0039] In the present embodiment, a kind of Na-doped novel Zintl phase thermoelectric material, its chemical formula is Yb 0.99 Na 0.01 Mg 2 Sb 2 , characterized in that it includes the following steps:

[0040] a. Using Na, Yb, Mg and Sb as raw materials in a glove box in an argon atmosphere environment, according to the target product chemical formula Yb 0.99 Na 0.01 Mg 2 Sb 2 The composition distribution ratio of 0.99:0.01:2:2 weighs each component and puts it into a ball mill jar equipped with grinding balls and seals it;

[0041] b. Put the ball mill jar in the above step a into a high-energy ball mill for alloying for 10-23 hours to obtain powder for later use;

[0042] c. Put the alloyed powder in the above step b into a graphite mold for hot pressing and sintering to 99% or more of the theoretical density to obtain the desired thermoelectric material Yb 0.9...

Embodiment 3

[0047] In this implementation, it is basically the same as in Embodiment 2, and the special features are:

[0048] In the present embodiment, a kind of Na-doped novel Zintl phase thermoelectric material, its chemical formula is Yb 0.98 Na 0.02 Mg 2 Sb 2 , characterized in that it includes the following steps:

[0049] a. Using Na, Yb, Mg and Sb as raw materials in a glove box in an argon atmosphere environment, according to the target product chemical formula Yb 0.98 Na 0.02 Mg 2 Sb 2 The composition distribution ratio of 0.98:0.02:2:2 weighs each component and puts it into a ball mill jar equipped with grinding balls and seals it;

[0050] b. Put the ball mill jar in the above step a into a high-energy ball mill for alloying for 2-16 hours to obtain powder for later use;

[0051] c. Put the alloyed powder in the above step b into a graphite mold for hot pressing and sintering to 99% or more of the theoretical density to obtain the desired thermoelectric material Yb 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap width | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com