Nano SiC/P-type silicon germanium alloy-based thermoelectric composite material and preparation method thereof

A nano-silicon carbide and silicon germanium alloy technology, which is applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc. Simple preparation method and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

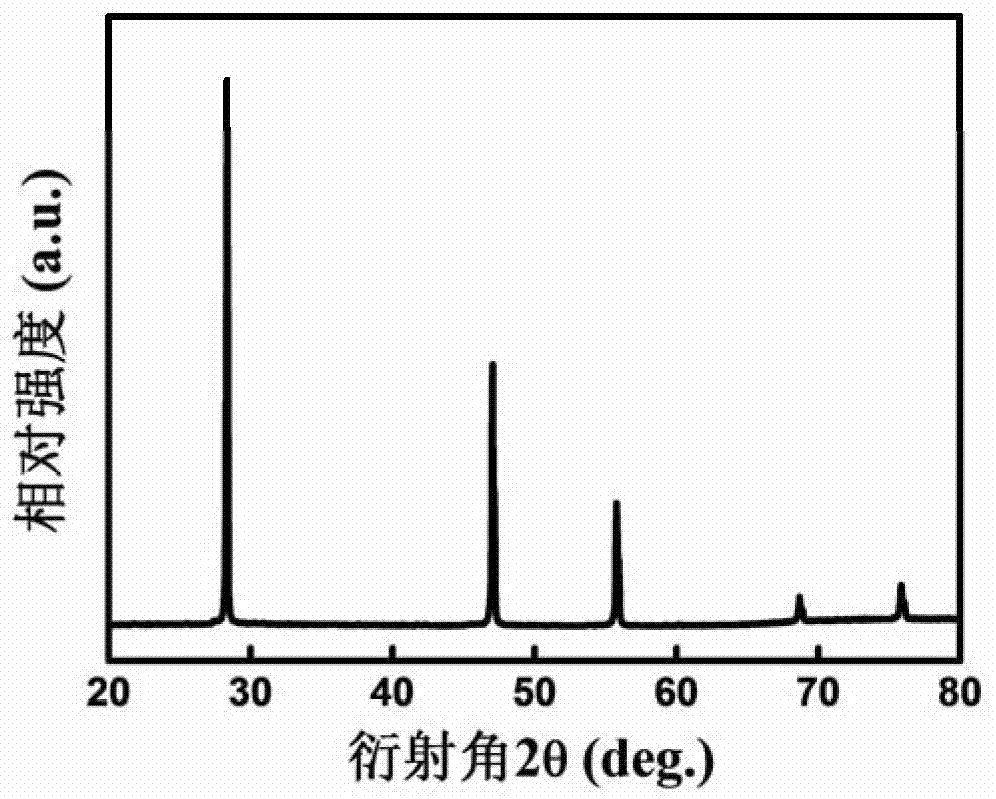

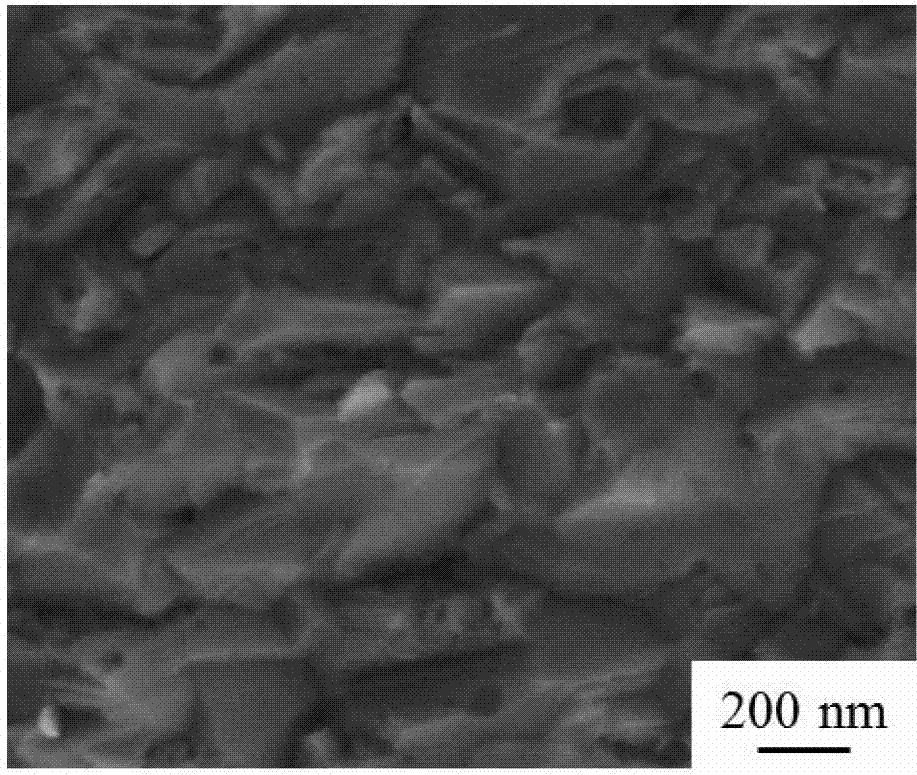

[0038] Example 1: P-type Si 80 Ge 20 B 1 +1.5vol% SiC nanocomposite thermoelectric material

[0039] First, according to Si 80 Ge 20 B 1 The stoichiometric ratio of Si, Ge, and B particles with a total amount of 10g was weighed as raw materials, and the raw materials were packaged in quartz tubes in a glove box, and Si was obtained by induction melting. 80 Ge 20 B 1 solid solution (melting temperature is 1400°C, melting time is 8 minutes), and crushed with a mortar to obtain Si 80 Ge 20 B 1 powder. Second, according to Si 80 Ge 20 B 1 1.5% of the powder volume fraction weighs silicon carbide particles with an average particle size of 100nm and Si 80 Ge 20 B 1 Powder mix. Then put the above-mentioned raw materials into a zirconia ball mill jar (volume is 80ml), and add grinding balls with a diameter of 10mm (the ratio of ball to material is 15:1). (Fritsch-Pulverisette-7) ball milling for 5 hours at a rotational speed of 600 rpm to obtain nanometer silicon car...

Embodiment 2

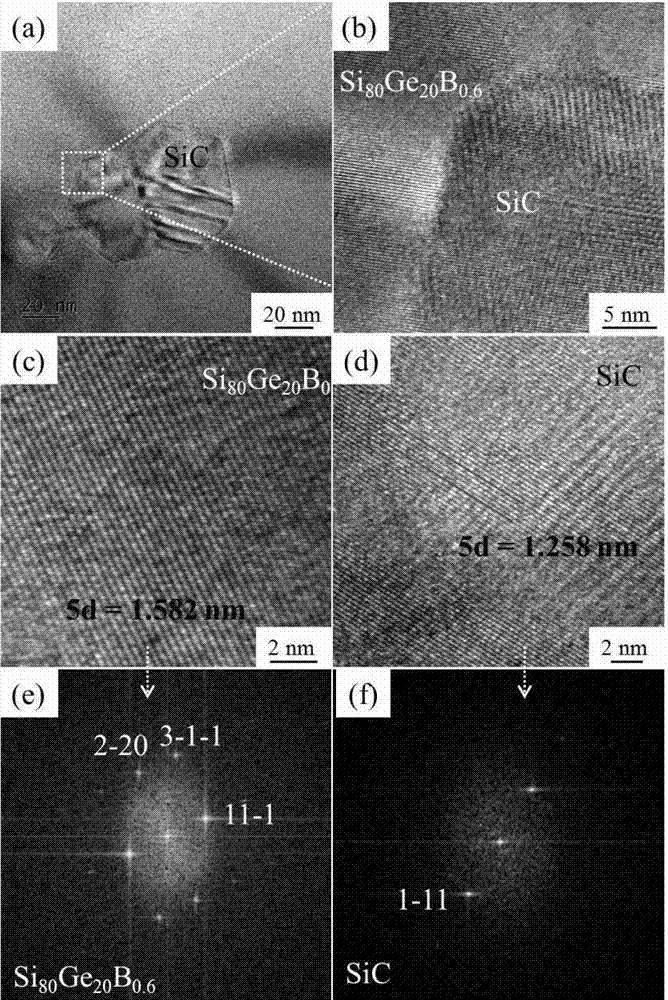

[0041] Example 2: P-type Si 80 Ge 20 B 0.6 +0.3vol% SiC nanocomposite thermoelectric material

[0042] First, according to Si 80 Ge 20 B 0.6 The stoichiometric ratio of Si, Ge, and B particles with a total amount of 10g was weighed as raw materials, and the raw materials were packaged in quartz tubes in a glove box, and Si was obtained by induction melting. 80 Ge 20 B 0.6 Si 80 Ge 20 B 0.6 powder. Second, according to Si 80 Ge 20 B 0.6 0.3% of the powder volume fraction weighs silicon carbide particles with an average particle size of 50nm and Si 80 Ge 20 B 0.6 Powder mix. Then put the above-mentioned raw materials into a zirconia ball mill jar (volume is 80ml), and add grinding balls with a diameter of 10mm (the ratio of ball to material is 15:1). (Fritsch-Pulverisette-7) ball milling 4h, rotating speed is 500rpm, obtains Si 80 Ge 20 B 0.6 +0.3vol% SiC nanocomposite thermoelectric material powder. Finally, put the powder into a graphite mold, and then ca...

Embodiment 3

[0044] Example 3: P-type Si 80 Ge 20 B 0.6 +0.5vol% SiC nanocomposite thermoelectric material

[0045] First, according to Si 80 Ge 20 B 0.6 The stoichiometric ratio of Si, Ge, and B particles with a total amount of 10g was weighed as raw materials, and the raw materials were packaged in quartz tubes in a glove box, and Si was obtained by induction melting. 80 Ge 20 B 0.6 Si 80 Ge 20 B 0.6 powder. Second, according to Si 80 Ge 20 B 0.6 0.5% of the powder volume fraction weighs silicon carbide particles with an average particle size of 50nm and Si 80 Ge 20 B 0.6Powder mix. Then put the above-mentioned raw materials into a zirconia ball mill jar (volume is 80ml), and add grinding balls with a diameter of 10mm (the ratio of ball to material is 15:1). (Fritsch-Pulverisette-7) ball milling 4h, rotating speed is 500rpm, obtains Si 80 Ge 20 B 0.6 +0.5vol% SiC nanocomposite thermoelectric material powder. Finally, put the powder into a graphite mold, and then car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com