Co-Sb series skutterudite compound thermoelectric material preparation method

A thermoelectric material and skutterudite technology, which is applied in the preparation field of Co-Sb series skutterudite compound thermoelectric materials, can solve the problem of high energy consumption, difficulty in obtaining single-phase skutterudite and filled skutterudite compound materials, cost higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

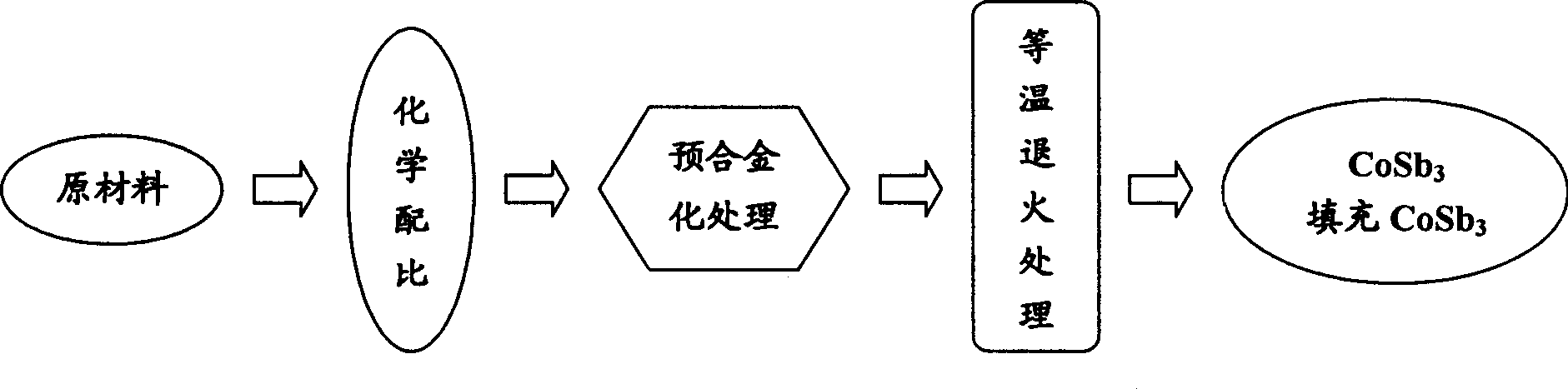

[0010] The method of the invention includes two material processing processes of prealloying and isothermal annealing. Firstly, through the mechanical alloying treatment of the original constituent materials, the constituent elements are uniformly mixed, and part of the skutterudite and filled skutterudite compounds are generated, while the structure of the material is refined, the diffusion distance between heterogeneous atoms is shortened, and the mixing system is improved. Gibbs free energy; then the material after the mechanical pre-alloying treatment is subjected to isothermal annealing treatment, and then a solid-phase reaction occurs to form a single-phase skutterudite compound.

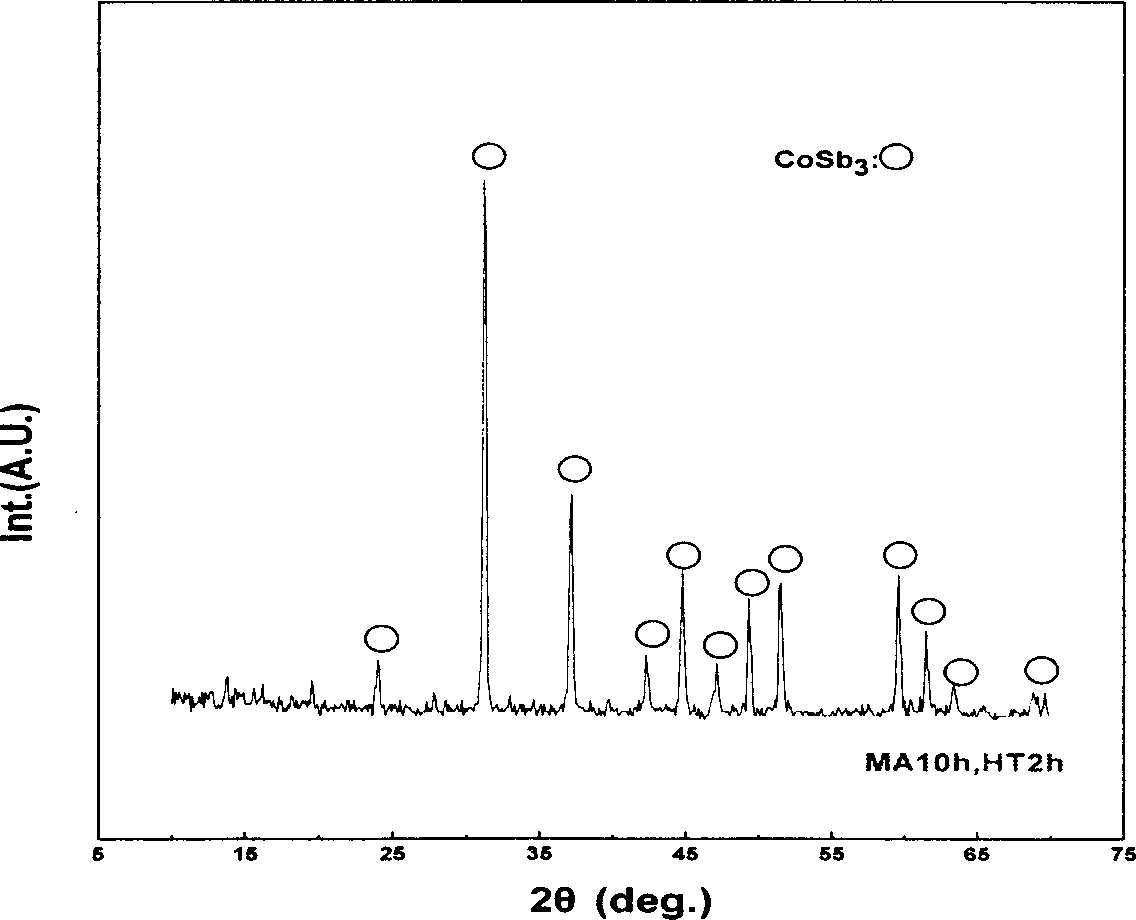

[0011] For CoSb 3 Compound, the raw material is Co, Sb elemental powder, according to the atomic ratio Co: Sb = 1:3 for stoichiometric proportioning, the prepared mixed powder is first subjected to pre-mechanical alloying treatment, mechanical alloying treatment is a high-energy ball milling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com