High-pressure synthesis preparation method of high-performance densification filled skutterudite thermoelectric material

A technology of filling skutterudite and high-pressure synthesis, which is applied in the high-pressure synthesis preparation of thermoelectric materials, high-performance densified filling skutterudite, and achieves the effects of short time, low temperature and superior mechanical processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

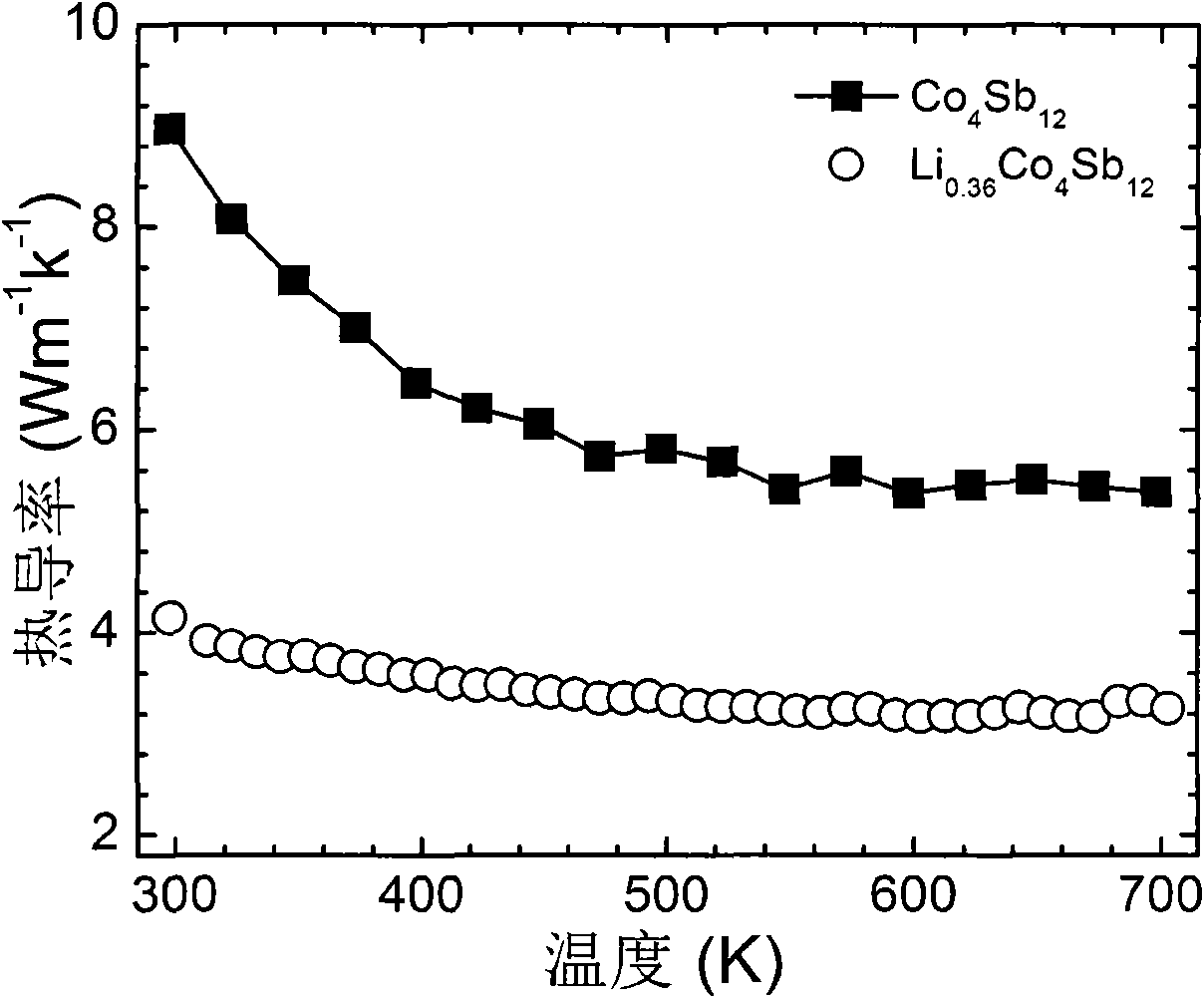

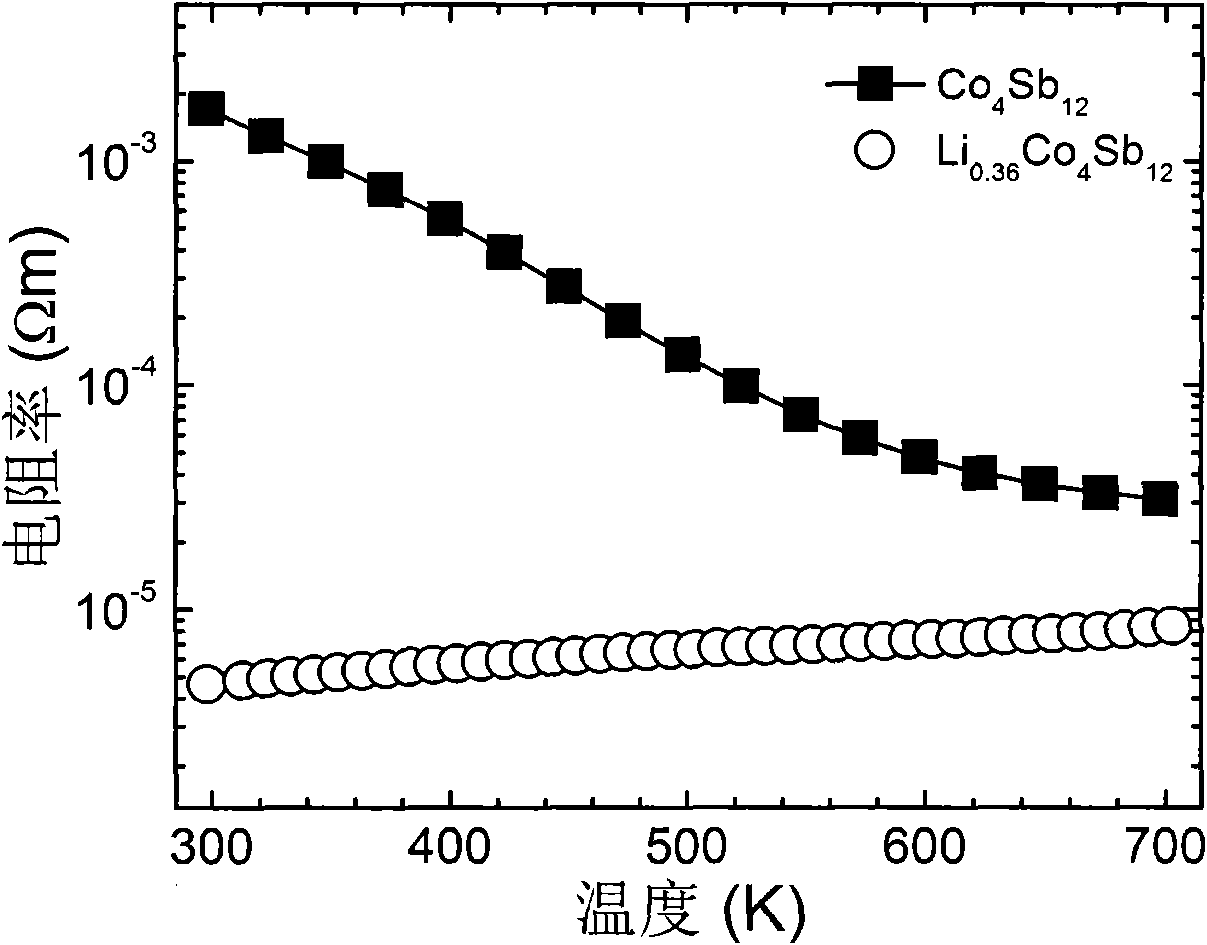

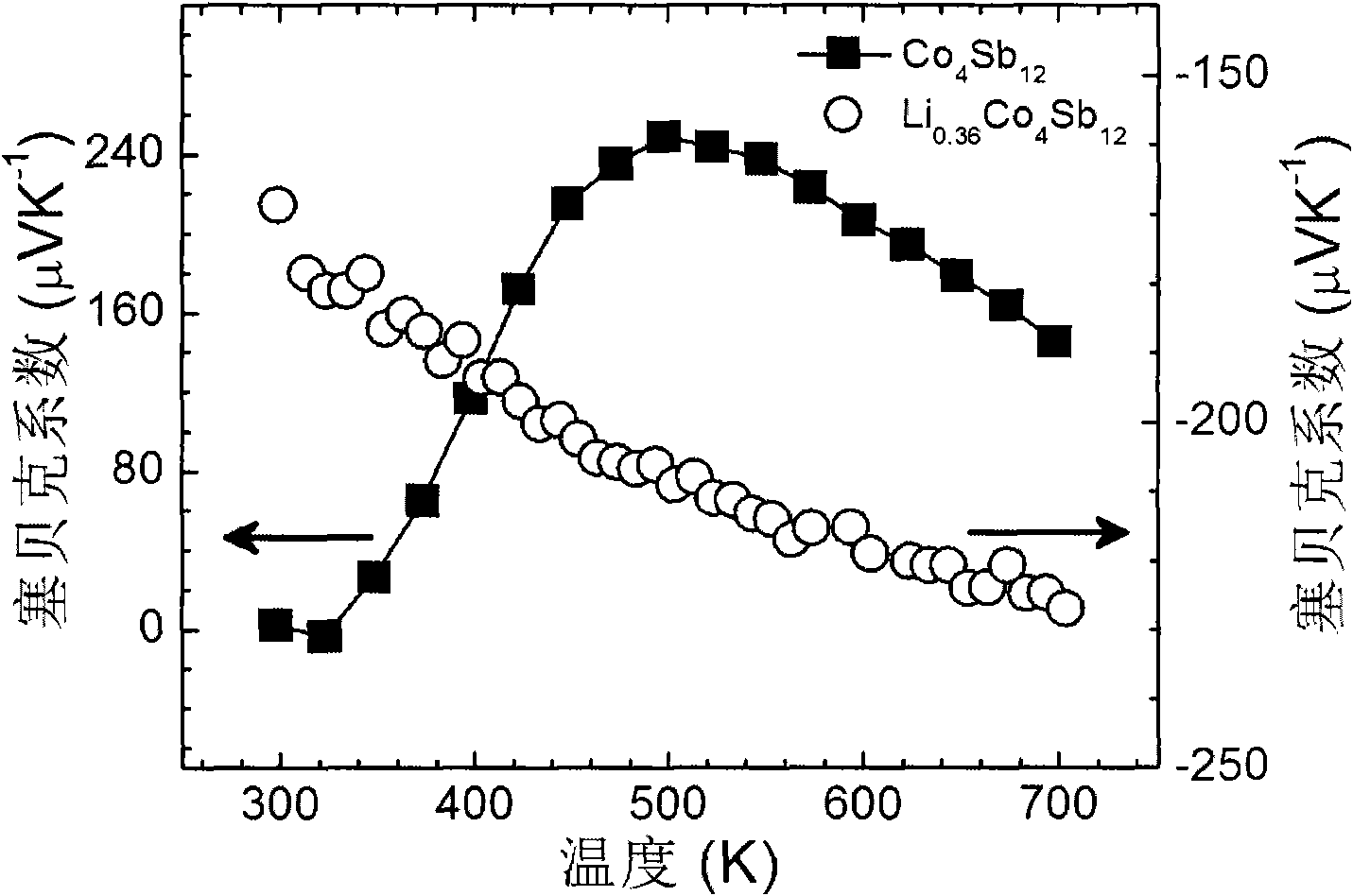

[0054] Example 1: High-performance densified Li-filled CoSb 3 Preparation method of thermoelectric material

[0055] (1) Using simple Li (99.99%, particle), Co (99.99%, powder) and Sb (99.99%, powder) as raw materials, according to Li 2 co 4 Sb 12 Weigh 8g of the stoichiometric ratio, put it into a 10.8mm mold and prepare a preform with a thickness of 16mm on a tablet press.

[0056] (2) Put the preform into a high-pressure mold composed of graphite, pyrophyllite and boron nitride crucible, and perform the first step of high-pressure synthesis in a hinged six-sided top press. Raise the pressure to 3GPa, heat to about 800°C, hold the heat for 30 minutes, then cool and release the pressure, take out the preform and grind it thoroughly, put it into a 10.8mm mold and prepare a transitional blank with a thickness of 14mm on a tablet press.

[0057] (3) Put the transition blank into a high-pressure mold composed of graphite, pyrophyllite and boron nitride crucible, and perform t...

Embodiment 2

[0060] Example 2: High performance densified Na-filled CoSb 3 Preparation method of thermoelectric material

[0061] (1) Using elemental Na (99.99%, particle), Co (99.99%, powder) and Sb (99.99%, powder) as raw materials, according to Na 2 co 4 Sb 12 Weigh 8g of the stoichiometric ratio, put it into a 10.8mm mold and prepare a preform with a thickness of 16mm on a tablet press.

[0062] (2) Put the preform into a high-pressure mold composed of graphite, pyrophyllite and boron nitride crucible, and perform the first step of high-pressure synthesis in a hinged six-sided top press. Raise the pressure to 1GPa, heat to about 750°C, hold the heat for 30 minutes, then cool and release the pressure, take out the preform and grind it thoroughly, put it into a 10.8mm mold and prepare a transitional blank with a thickness of 14mm on a tablet press.

[0063] (3) Put the transition blank into a high-pressure mold composed of graphite, pyrophyllite and boron nitride crucible, and perfor...

Embodiment 3

[0066] Example 3: High performance densified Ca-filled CoSb 3 Preparation method of thermoelectric material

[0067] (1) Using elemental Ca (99.99%, powder), Co (99.99%, powder) and Sb (99.99%, powder) as raw materials, according to Ca 2 co 4 Sb 12 Weigh 8g of the stoichiometric ratio, put it into a 10.8mm mold and prepare a preform with a thickness of 16mm on a tablet press.

[0068] (2) Put the preform into a high-pressure mold composed of graphite, pyrophyllite and boron nitride crucible, and perform the first step of high-pressure synthesis in a hinged six-sided top press. Raise the pressure to 1GPa, heat to about 800°C, hold the heat for 30 minutes, then cool and release the pressure, take out the preform and grind it thoroughly, put it into a 10.8mm mold and prepare a transitional blank with a thickness of 14mm on a tablet press.

[0069](3) Put the transition blank into a high-pressure mold composed of ink, pyrophyllite and boron nitride crucible, and perform the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com