Modified asphalt with flame retardance and hot-mix emission reduction functions

A modified asphalt and hot mix technology, applied in the field of materials, can solve the problems of smoke emission, flammability of traffic accidents, etc., and achieve the effect of improving safety performance, good flame retardant and hot mix emission reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

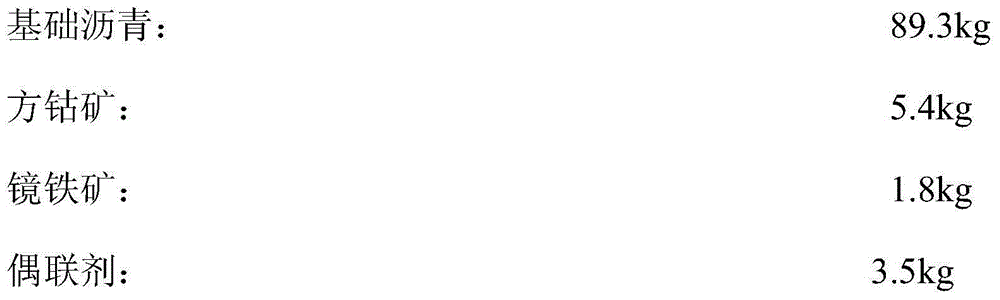

[0011] Taking the production of product 100kg of the present invention as an example, the raw materials used and their weight proportions are:

[0012]

[0013] The above basic asphalt adopts SBS modified asphalt; the above-mentioned skutterudite and specularite are both 2000 mesh, and can also be replaced by other meshes; the coupling agent uses silane coupling agent, the purpose is to modify the surface of skutterudite and specularite and improve the compatibility of the two minerals with asphalt.

[0014] Select the reaction raw materials according to the above-mentioned raw materials and their mass percentages; dry the specularite and skutterudite and add them to the coupling agent treatment solution with ethanol as the solvent to soak for 2 hours, stir slightly during the soaking process, and dry them to prepare Surface-modified specularite and skutterudite composite modifier; the basic asphalt is heated to 150±5°C, and the surface-modified specularite and skutterudite...

Embodiment 2

[0016] Taking the production of product 100kg of the present invention as an example, the raw materials used and their weight proportions are:

[0017]

[0018]

[0019] The above-mentioned base asphalt is SBS modified asphalt; the above-mentioned skutterudite and specularite are both 2000 mesh, and can also be replaced by other meshes; the coupling agent is a silane coupling agent, and its preparation method is the same as that of Example 1.

Embodiment 3

[0021] Taking the production of product 100kg of the present invention as an example, the raw materials used and their weight proportions are:

[0022]

[0023] The above-mentioned base asphalt is SBS modified asphalt; the above-mentioned skutterudite and specularite are both 2000 mesh, and can also be replaced by other meshes; the coupling agent is a silane coupling agent, and its preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com