Method for preparing skutterudite base thermoelectric block body material

A technology of bulk materials and thermoelectric materials, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

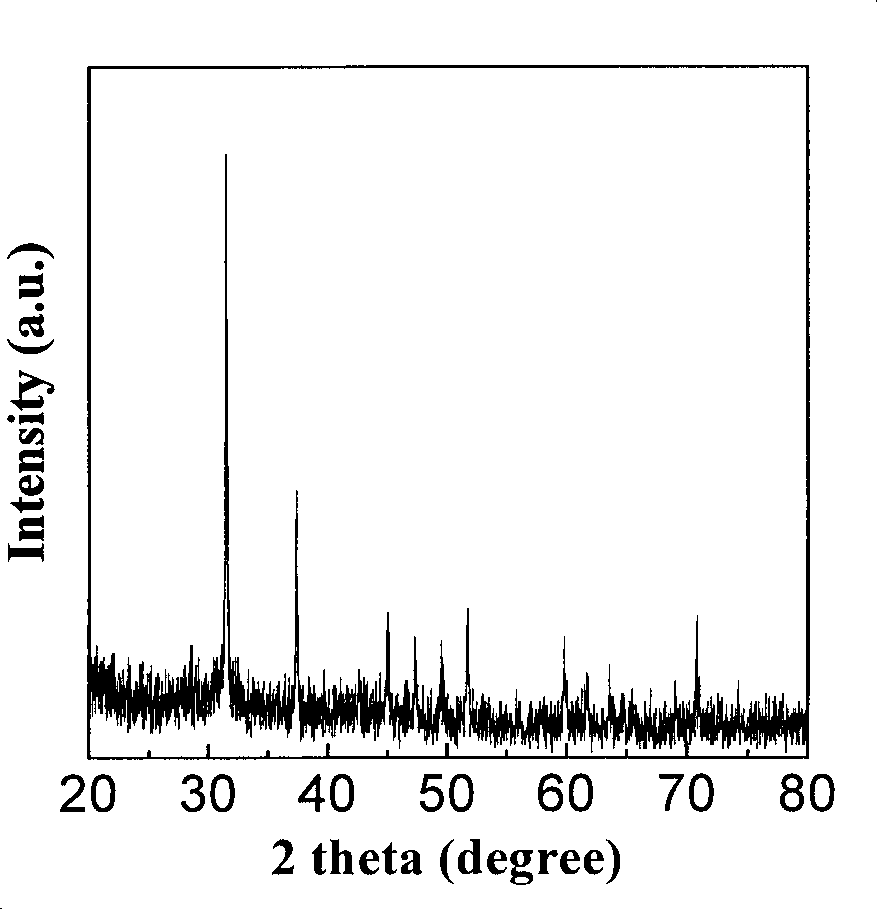

[0022] In 0.1 co 4 Sb 12 Preparation of thermoelectric materials

[0023] 1. Synthesis process

[0024] 1. Ingredients

[0025] Add about 40ml of absolute ethanol to a 100ml polytetrafluoroethylene tank, add 4.48g of KOH or NaOH, stir slightly, and calculate the theoretical output as 2g, according to In 0.1 co 4 Sb 12 Stoichiometric addition of CoCl in sequence 2 ·6H 2 O, SbCl 3 , InCl 3 4H 2 O, KBH 4 1.114g, 3.205g, 0.034g, 2.8g, respectively, and then stir evenly, and finally add absolute ethanol to a total volume of about 80-85ml, cover it, and put it into an autoclave.

[0026] 2. Solvothermal reaction

[0027] Put the high-pressure reaction kettle into the heating furnace and raise the temperature to 180-200°C at a rate of 5-10°C / min for 48 hours, and then naturally cool to room temperature.

[0028] 3. Washing

[0029] Pour off the clarified solvent in the upper layer of the reaction kettle, stir the black product with an appropriate amount of deionized wa...

example 2

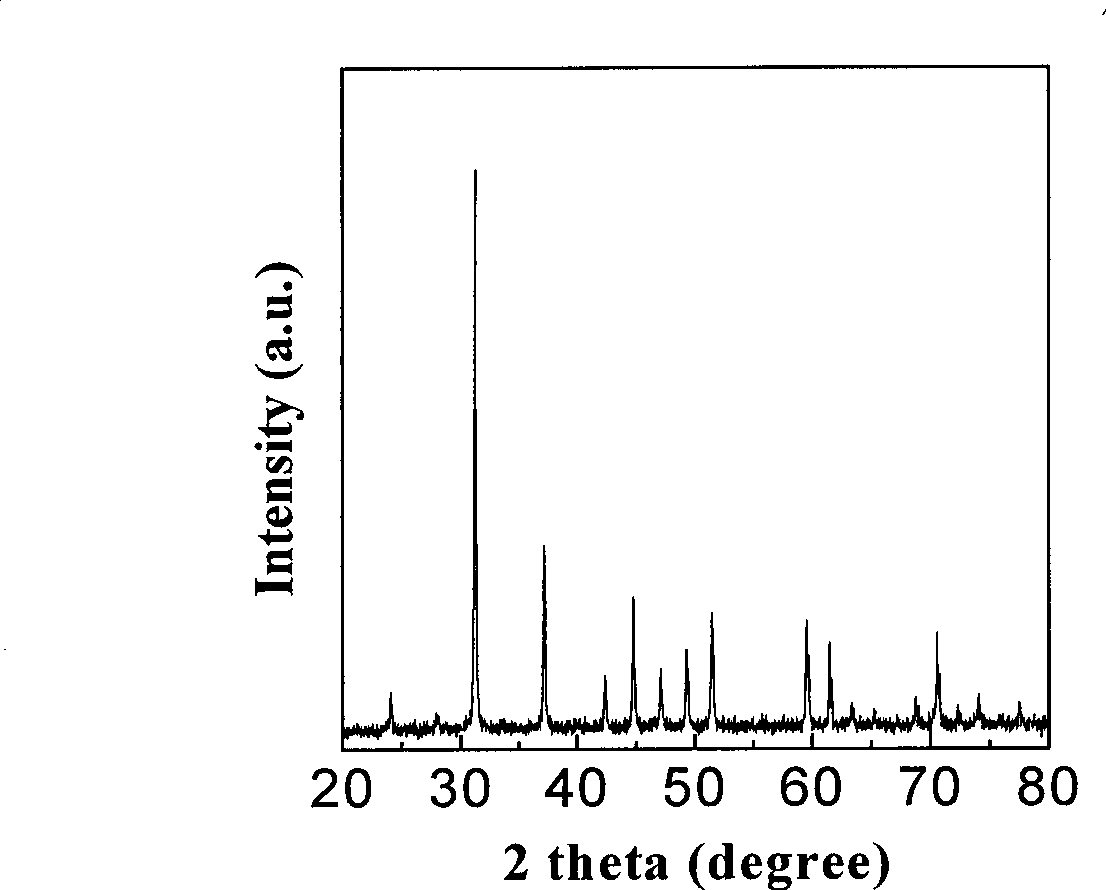

[0044] In 0.1 co 3.7 Ni 0.3 Sb 12 Preparation of thermoelectric materials

[0045] 1. Synthesis process

[0046] 1. Ingredients

[0047] Add about 40ml of absolute ethanol to a 100ml polytetrafluoroethylene tank, add 4.48g of KOH or NaOH, stir slightly, and calculate the theoretical output as 2g, according to In 0.1 co 3.7 Ni 0.3 Sb 12 Add the corresponding amount of CoCl sequentially in the stoichiometric ratio 2 ·6H 2 O, SbCl 3 , InCl 3 4H 2 O, NiCl 2 ·6H 2 O, KBH 4 About 1.03g, 3.205g, 0.034g, 0.083g, 2.8g respectively, then stir evenly, and finally add absolute ethanol until the total volume reaches 80-85ml, cover it, and put it into the autoclave.

[0048] 2. Constant temperature reaction

[0049] Put the high-pressure reaction kettle into the heating furnace and raise the temperature to 180-200°C at a rate of 5-10°C / min for 48 hours, and then naturally cool to room temperature.

[0050] 3. Washing

[0051] Pour off the clarified solvent in the upper la...

specific example 3

[0057] In 0.2 co 4 Te 0.2 Sb 11.8 Preparation of thermoelectric materials

[0058] 1. Synthesis process

[0059] 1. Ingredients

[0060] Add about 40 ml of absolute ethanol to a 100ml polytetrafluoroethylene tank, add 4.48 grams of KOH or NaOH, stir slightly, and calculate the theoretical output as 2 grams, according to In 0.2 co 4 Te 0.2 Sb 11.8 Stoichiometric addition of CoCl in sequence 2 ·6H 2 O, SbCl 3 , InCl 3 4H 2 O, Na 2 TeO 3 , KBH 4 They are 1.106g, 3.129g, 0.068g, 0.028g, 2.8g respectively, stir evenly, and finally add absolute ethanol until the total volume reaches 80-85ml, cover it, and put it into the autoclave.

[0061] 2. Constant temperature reaction

[0062] Put the closed autoclave into the heating equipment, react at a constant temperature of 180-200°C for 48 hours, and then cool down to room temperature naturally.

[0063] 3. Washing

[0064] Pour off the clarified solvent in the upper layer of the reaction kettle, stir the black product w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com