Multiple filling skutterudite thermoelectric material and preparation process thereof

A technology for filling skutterudite and thermoelectric materials, applied in the direction of the lead wire material of thermoelectric device junctions, etc., can solve the problems of reduced thermal conductivity, complicated process, difficulty in obtaining pure multi-filled skutterudite compounds, etc. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Sr 0.25 Yb 0.1 co 4 Sb 12 Material

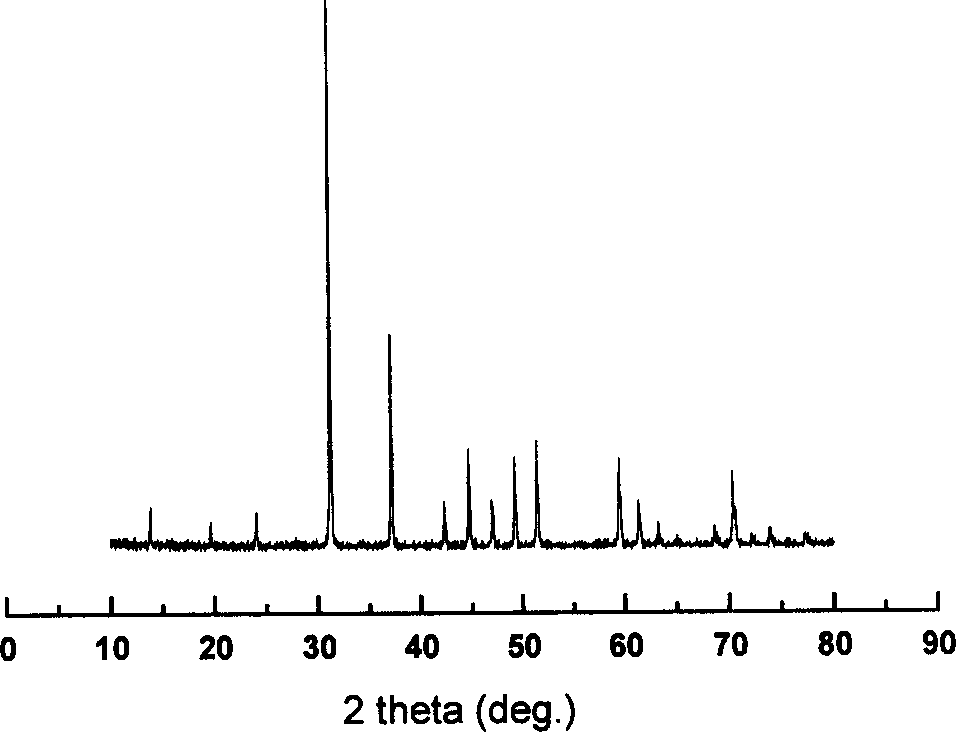

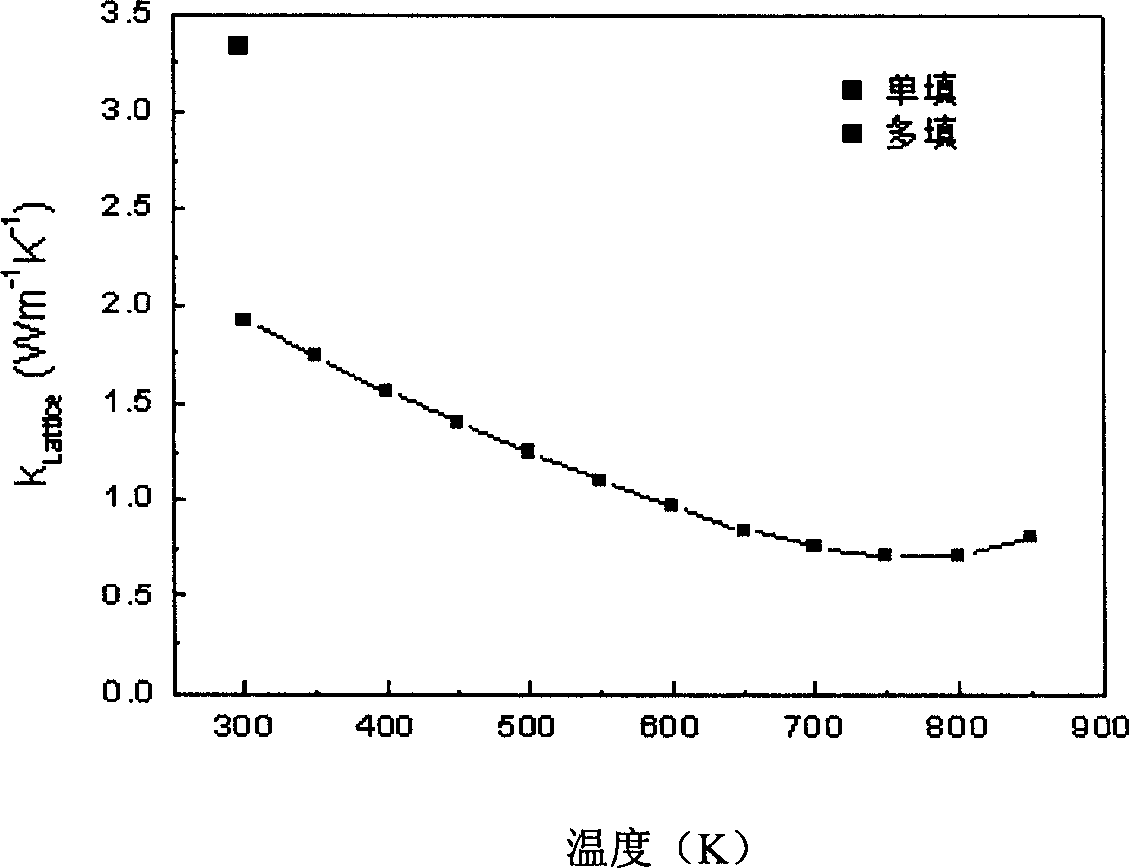

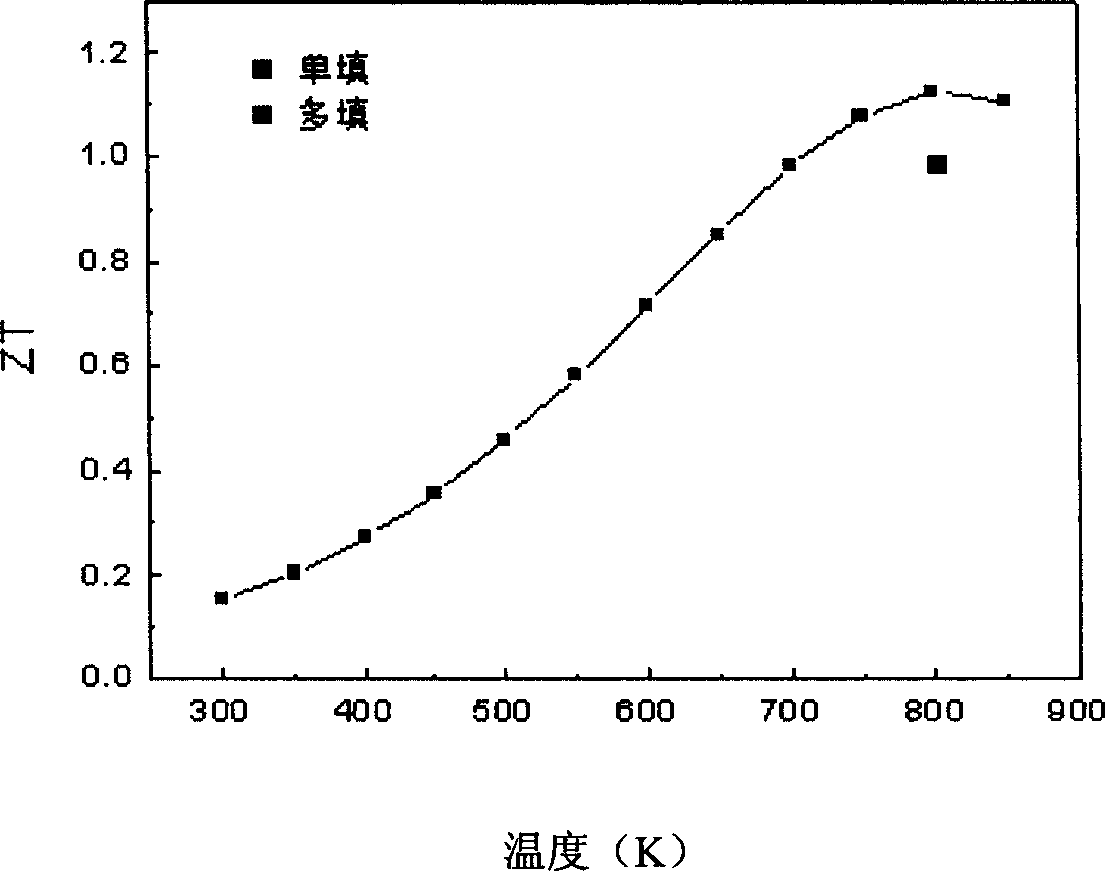

[0019] The metal raw materials Sr, Yb, Co, and Sb are mixed according to the molar ratio of 0.25:0.1:4:12, sealed in a quartz tube, and a small amount of Ar gas is filled in the quartz tube for protection. The mixed raw materials were melted at 1000° C. for 3.5 hours. Quenching is carried out after melting, the quenching medium is oil, and the quenching speed is about 150°C / s. X-ray diffraction analysis showed that the synthesized material was pure Sr 0.25 Yb 0.1 co 4 Sb 12 Filled with skutterudite material (see figure 1 ). Thermal conductivity tests show that Sr 0.25 Yb 0.1 co 4 Sb 12 Multi-filled materials have a higher ratio than (single) filled skutterudite Sr y co 4 Sb 12 Lower lattice thermal conductivity (see figure 2 ). ZT value calculation results show that Sr 0.25 Yb 0.1 co 4 Sb 12 Multi-filled skutterudite materials have excellent thermoelectric properties (see image 3 ).

Embodiment 2

[0020] Example 2: Sr 0.2 Ce 0.2 co 3.0 Fe 1.0 Sb 12 Material

[0021] The metal raw materials Sr, Ce, Co, Fe, Sb are compounded according to the molar ratio of 0.2:0.2:3:1:12, sealed in a quartz tube, and the inside of the quartz tube is vacuumed. The mixed raw materials were melted at 1050° C. for 1 hour. Quenching is carried out after the melting is completed, the quenching medium is water, and the quenching speed is about 200°C / s. X-ray diffraction analysis showed that the synthesized material was Sr 0.25 Ce 0.05 co 3.0 Fe 1.0 Sb 12 Filled with skutterudite material.

Embodiment 3

[0022] Example 3: Ca 0.05 Eu 0.25 co 3.5 Ni 0.5 Sb 11.95 Te 0.05 Material

[0023] The metal raw materials Ca, Eu, Co, Ni, Sb, Te are mixed according to the molar ratio of 0.05:0.25:3.5:0.5:11.95:0.05, sealed in a quartz tube, and a small amount of Ar gas is filled in the quartz tube for protection. The mixed raw materials were melted at 1025° C. for 2.5 hours. Quenching is carried out after the melting is completed, the quenching medium is brine, and the quenching speed is about 300°C / s. X-ray diffraction analysis showed that the synthesized material was Ca 0.05 Eu 0.25 co 3.5 Ni 0.5 Sb 11.95 Te 0.05 Filled with skutterudite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com