Pyroelectric material with quadruple skutterudite structure and preparation method thereof

A kind of thermoelectric material, Yuanfang technology, applied in the direction of thermoelectric device junction lead wire material, etc., to achieve the effect of simple equipment, improving thermoelectric figure of merit, and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

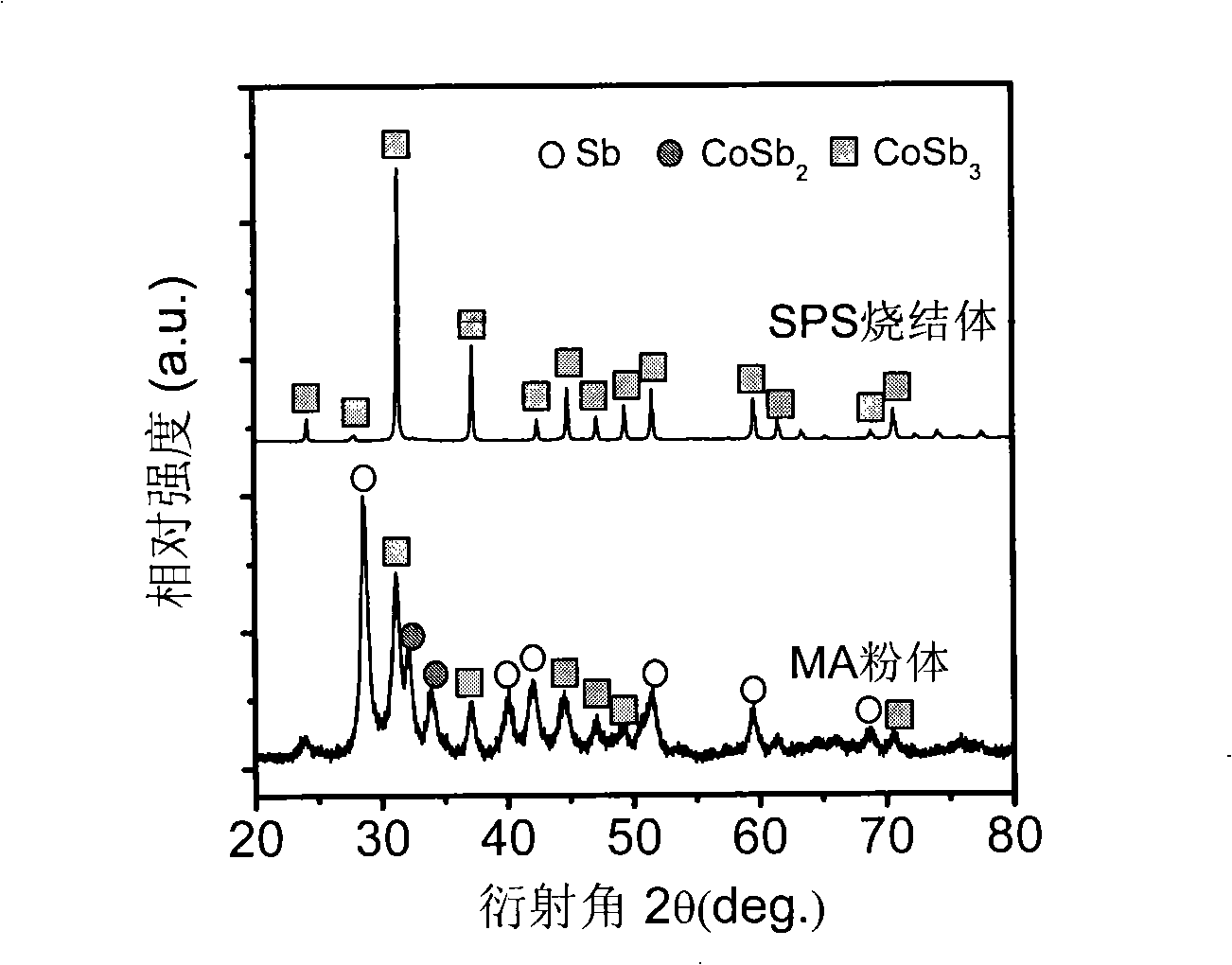

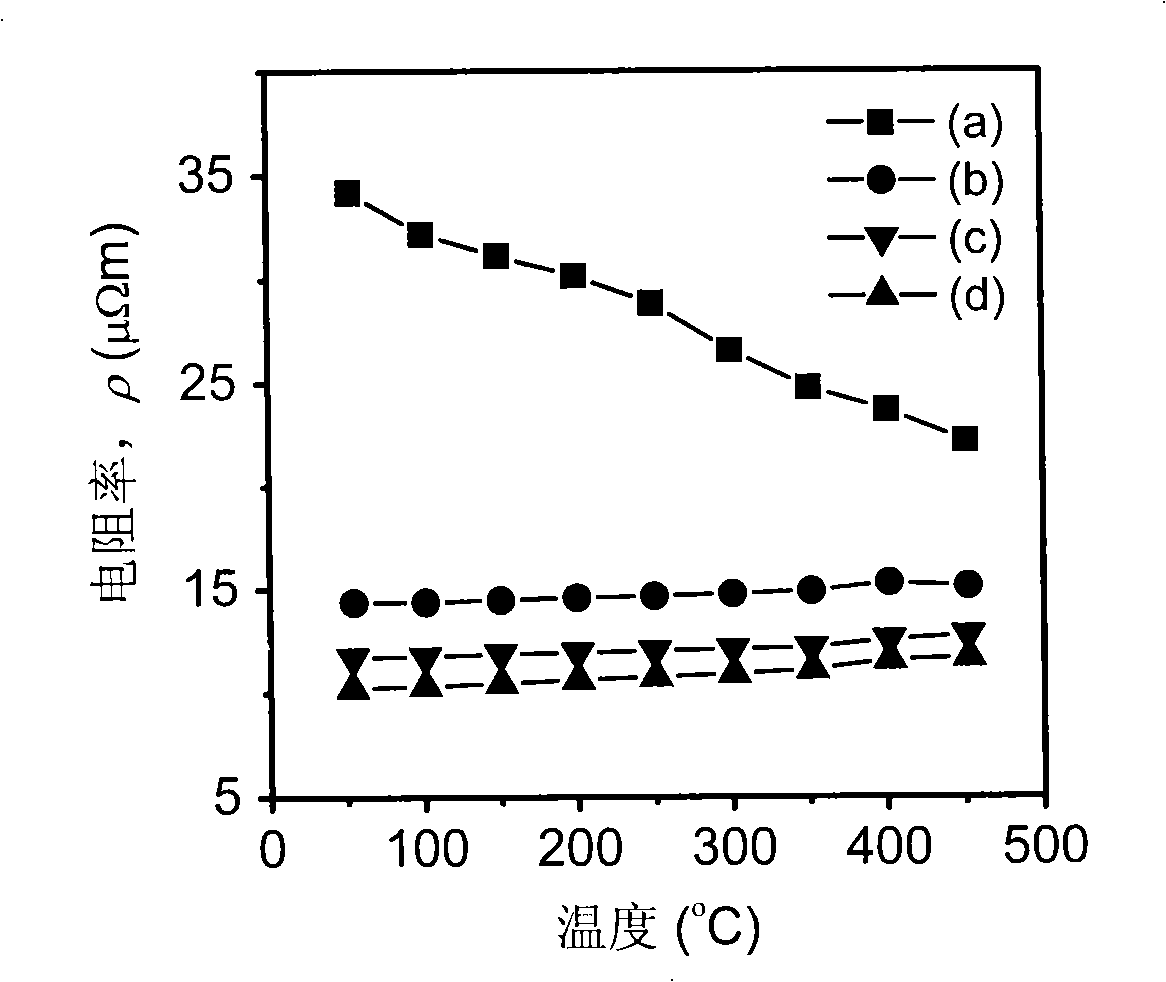

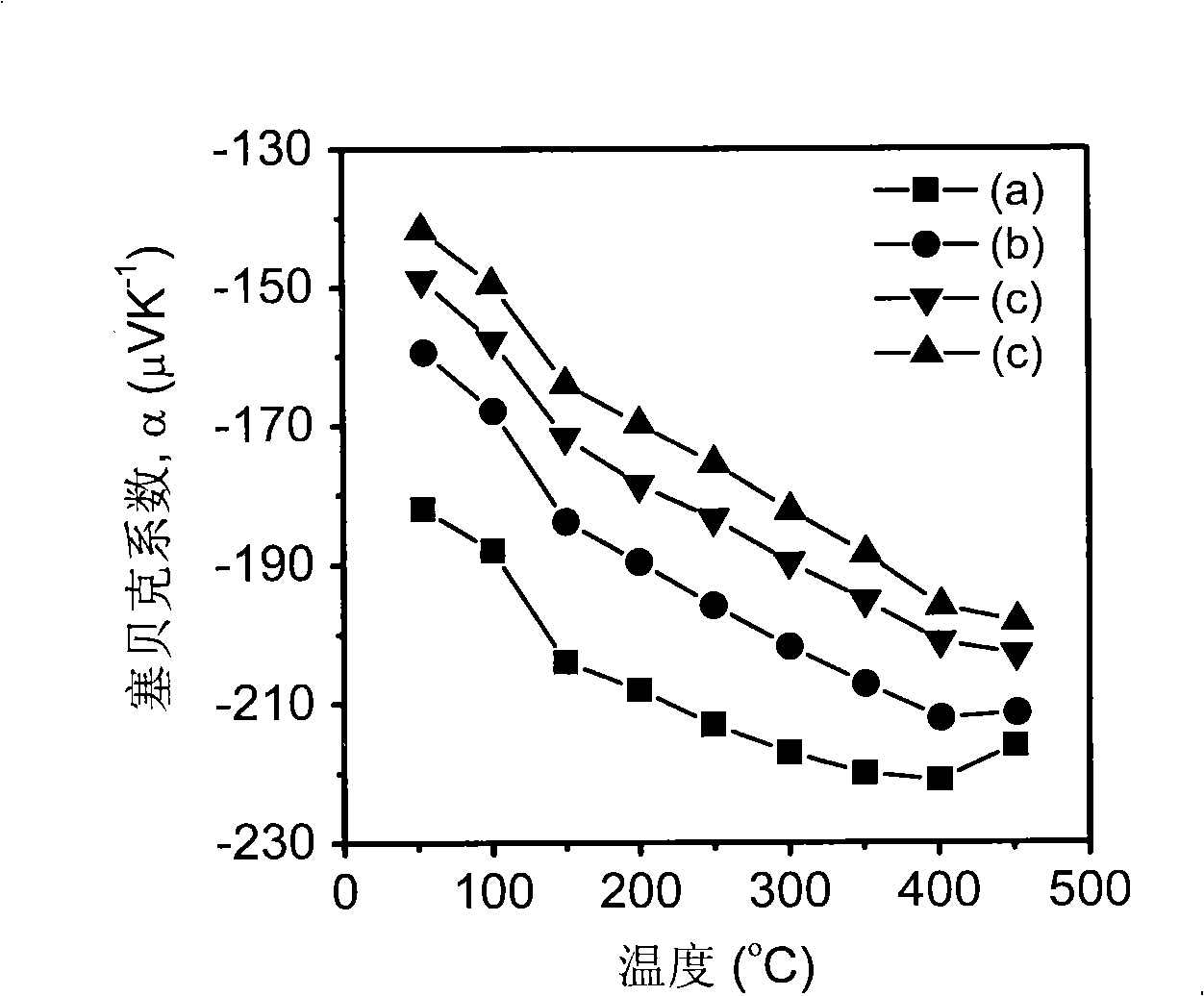

[0028] Embodiment 1: with cobalt (Co) powder, antimony (Sb) powder, tellurium (Te) powder, germanium (Ge) powder is raw material according to CoSb 3+δ-x-y x x Y y (X=Te, Y=Ge; δ=0.06, x=0.12, y=0.02), ie CoSb 2.92 Te 0.12 Ge 0.02The metering ratio of weighing a total amount of powder is 20g, put it into a stainless steel tank (volume 250ml), and add stainless steel balls with a diameter of 6-20mm (the weight ratio of grinding balls and powder is 25:1). The ball mill jar was filled with Ar gas as a protective gas, and then the ball mill jar was installed in a planetary ball mill (QM-2, Nanjing University Instrument Factory), and ball milled at a speed of 450 rpm for 6 hours to obtain a fine powder. Take out the ball-milled powder, put it into a graphite mold, and then put it into a spark plasma sintering equipment for sintering. The sintering temperature is 600° C., the holding time is 5 minutes, the sintering pressure is 30 MPa, and the heating rate is 100° C. / min. figur...

Embodiment 2

[0029] Embodiment 2: with cobalt (Co) powder, antimony (Sb) powder, selenium (Se) powder, tin (Sn) powder is raw material according to CoSb 3+δ-x-y x x Y y The metering ratio of (X=Se, Y=Sn; δ=0.1, x=0.001, y=0.001) weighs a total amount of 20g powder, and its MA-SPS process is the same as in Example 1. The thermoelectric performance test results show that the compound is n-type with a power factor of 500μWm -1 K -2 .

Embodiment 3

[0030] Embodiment 3: with cobalt (Co) powder, antimony (Sb) powder, tellurium (Te) powder, tin (Sn) powder is raw material according to CoSb 3+δ-x-y x x Y y (X=Te, Y=Sn; δ=0, x=0.125, y=0.125), namely CoSb 2.75 Te 0.125 sn 0.125 The metering ratio weighs a total amount of powder that is 20g. Then put the powder into a stainless steel jar (volume 250ml), and add stainless steel balls with a diameter of 6-20mm (the weight ratio of grinding balls and powder is 25:1). The ball milling jar was filled with Ar gas as a protective gas, and then the ball milling jar was installed in a planetary ball mill (QM-2, Nanjing University Instrument Factory), and ball milled at a speed of 450 rpm for 15 hours to obtain a fine powder. Take out the ball-milled powder, put it into a graphite mold, and then put it into a spark plasma sintering equipment for sintering. The sintering temperature is 500° C., the holding time is 5 minutes, the sintering pressure is 50 MPa, and the heating rate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com