Skutterudite based thermoelectric material, thermal protection coating for devices and preparation method thereof

A thermoelectric material and thermal protection technology, which can be used in thermoelectric device parts, coatings, etc., and can solve problems such as reducing the efficiency of thermoelectric devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

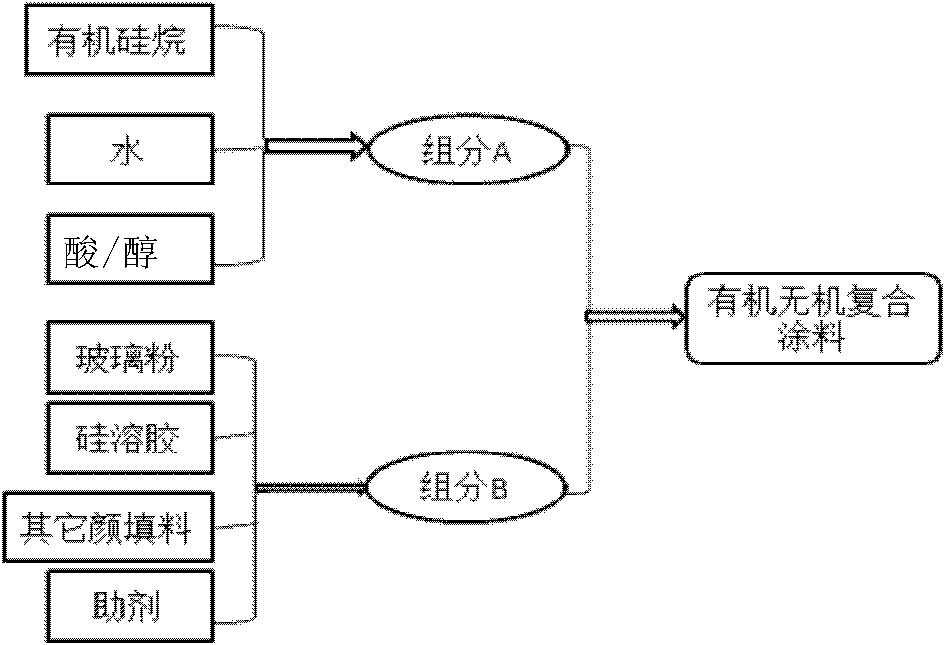

[0061] In a second aspect of the present invention, a method for preparing a skutterudite-based thermoelectric material and a thermal protection coating for a device is provided, the method comprising:

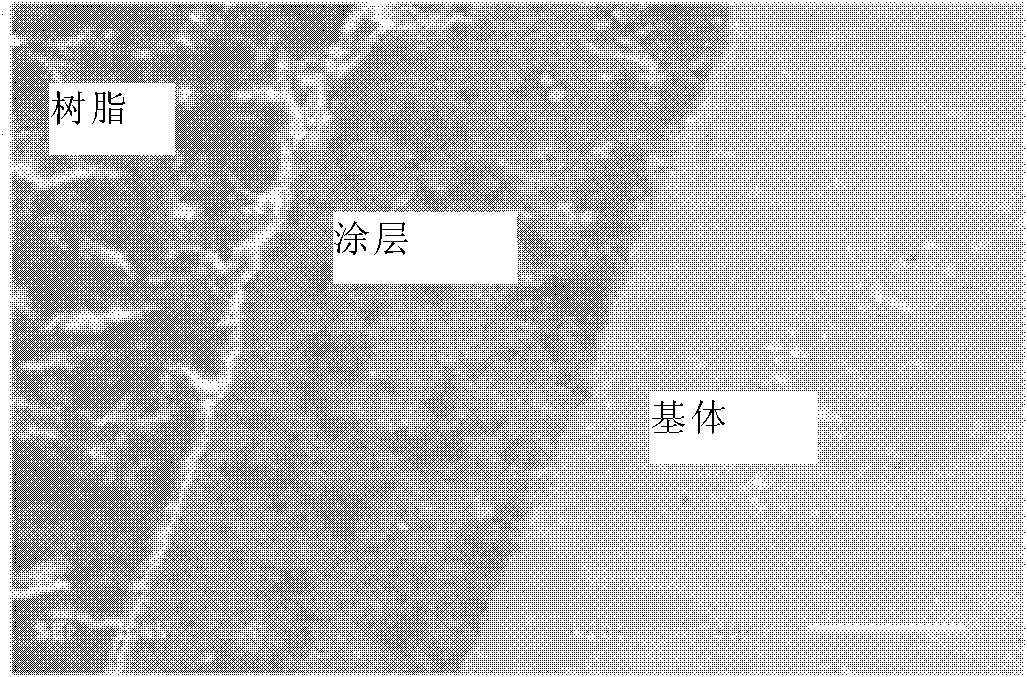

[0062] The organosilicon sol obtained after the hydrolysis and polymerization of the organosilane coupling agent at 4-80°C is the component A; the inorganic water-based silica sol is mixed with glass powder and other powder materials according to a certain ratio, and an appropriate amount of additives is added, and the mixture is evenly mixed by ball milling Component B is finally obtained; the organic component A and the inorganic component B are blended and stirred evenly, and then coated on the surface of the surface-treated skutterudite-based thermoelectric material to obtain an organic-inorganic composite heat-resistant and anti-oxidation coating .

[0063] In the present invention, the prepared composite slurry can be applied by various coating methods such as dip coatin...

Embodiment 1

[0077] Take 15.00 g of methyltrimethoxysilane, 5.00 g of ethanol, and 5.01 g of water, adjust the pH to 3-4 with nitric acid, and bathe in oil at 60°C for 10 minutes to obtain component A. Mix glass powder and silica sol uniformly at a ratio of 1:1 (parts by weight) to obtain component B. Blend B and A at a ratio of 1:5, and stir evenly to obtain the desired slurry. Apply the slurry on the surface of the skutterudite-based thermoelectric material that has been sandblasted (the π-type device is polished to 400 mesh), ultrasonically cleaned, and dried at 80°C, and cured once in a vacuum drying oven at 100°C×2 hours at a low temperature to obtain a coating.

Embodiment 2

[0079] Preparation of Component A: Blend 13.61 grams of methyltrimethoxysilane with 5.4 grams of deionized water adjusted to pH 4-5 with nitric acid, and stir in a water bath at 60°C for 20 minutes to obtain Component A, which is Hydrolyzed polymer product of methyltrimethoxysilane.

[0080] Preparation of Component B: Blend 4.99 g of glass powder with 5.09 g of silica sol, add an appropriate amount of dispersant and other additives, and ball mill at 206 rpm for 5 hours to obtain Component B. Next, component A was added to component B, and ball milled at 150 rpm for 20 minutes to obtain an organic-inorganic composite slurry. Coat it on the surface of the skutterudite-based thermoelectric material that has been sandblasted (the π-type device is ground to 400 mesh), ultrasonically cleaned, and dried at 80°C, cured once, and preheated in air: 60°C×4 hours , and then 100 °C x 2 hours. That is, a non-vitrified primary cured coating is obtained.

[0081] The slurry of Example 2 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com