Automatic pressure relief valve and data disaster recovery storage device comprising same

A storage device and automatic leakage technology, applied in valve devices, reducing physical parameters of carriers, balancing valves, etc., can solve problems such as poor heat resistance durability, achieve precise temperature control protection function, anti-corrosion data security, and improve heat resistance. lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

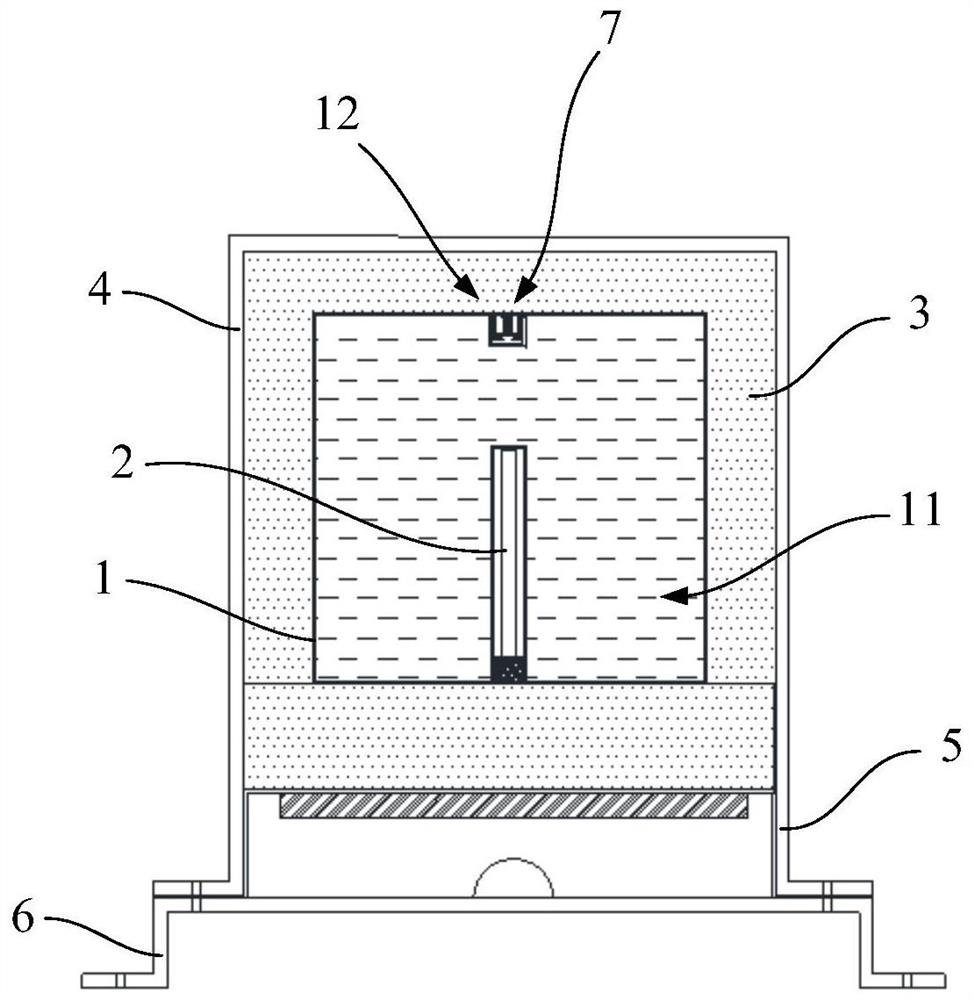

[0070] Such as figure 1 and figure 2 Shown is Embodiment 1 of the present invention. This embodiment provides a data disaster recovery storage device. The data disaster recovery storage device includes an inner tank 1 with a hollow cavity 11, and the hollow cavity 11 is filled with cooling liquid, and the cooling liquid surrounds Data Storage 2. Specifically in this embodiment, the outer wall of the liner 1 is inwardly recessed to form a groove for accommodating the data storage device 2, that is, the wall of the groove is integrally connected with the wall of the liner 1, specifically by welding, or sheet metal stamping, Or the way of flange installation to realize the above structure, which is not limited in the present invention. Through this structure, the data storage 2 can be installed outside the inner tank 1 without affecting the protection of the data storage 2 by the cooling liquid.

[0071] The inner tank 1 has an opening 12 through which cooling liquid can be i...

Embodiment 2

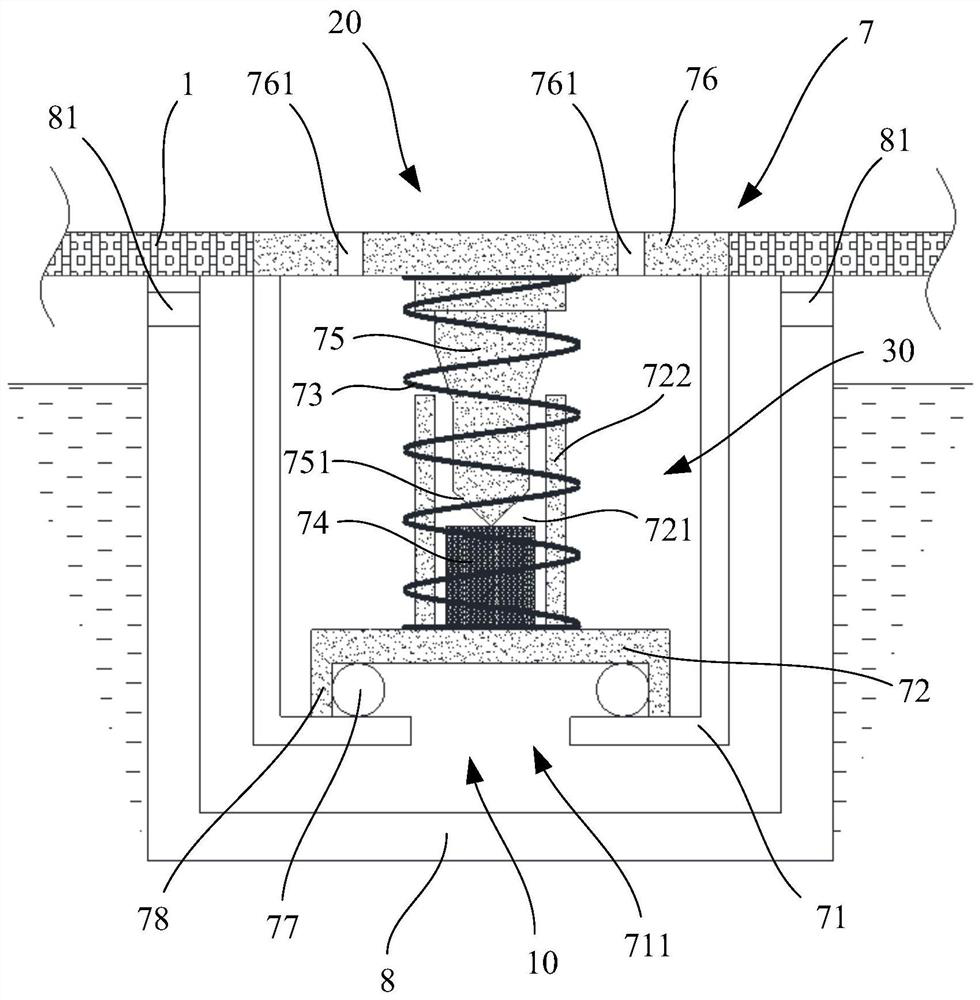

[0089] Such as image 3 Shown is Embodiment 2 of the present invention. The automatic pressure relief valve provided by this embodiment is basically the same as the automatic pressure relief valve of Embodiment 1. The difference is that in this embodiment, the movable part 72 is provided with a direction The plunger 723 protrudes from the pressure relief hole 711 , and the plunger 723 cooperates with the pressure relief hole 711 to improve the sealing performance of the pressure relief hole 711 . When the pressure difference causes the plunger 723 to escape from the pressure relief hole 711 , the pressure relief hole 711 is opened, and the high temperature and high pressure steam can be discharged through the pressure relief hole 711 . In this embodiment, the pressure relief hole 711 is completely filled by the plunger 723 to ensure that the pressure relief hole 711 is sealed.

Embodiment 3

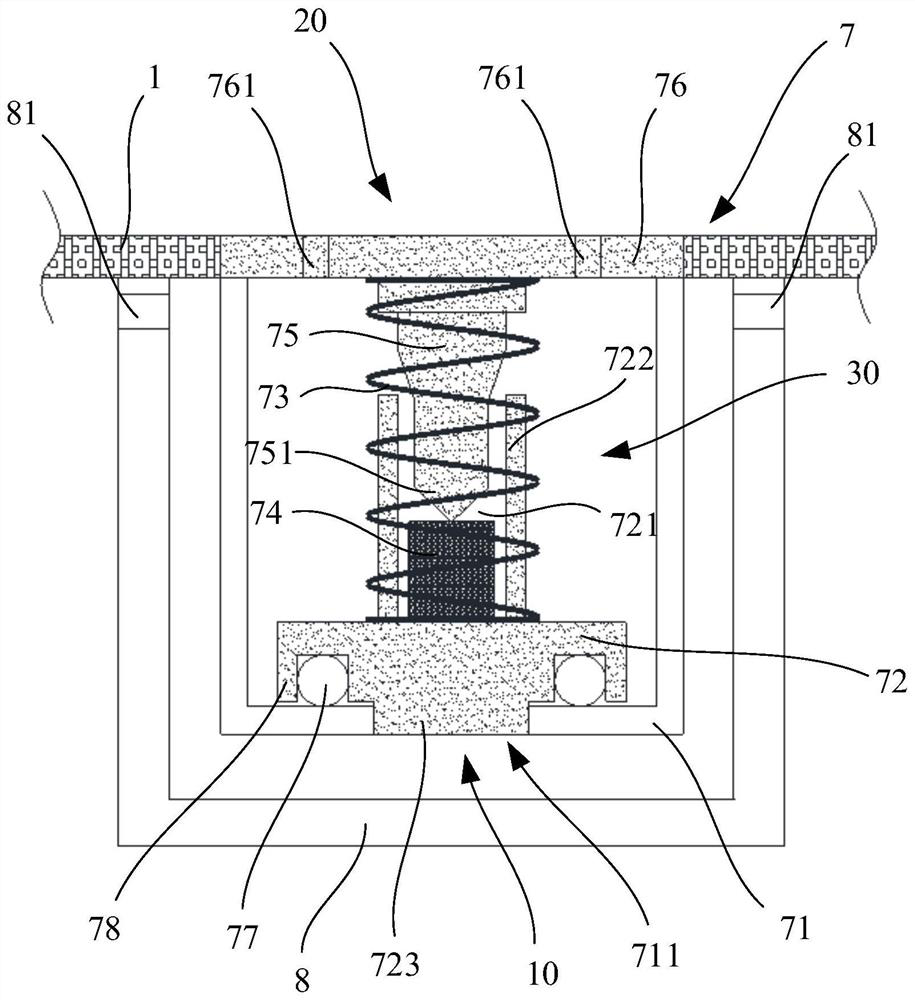

[0091] Such as Figure 4 Shown is Embodiment 3 of the present invention, the automatic pressure relief valve provided by this embodiment is basically the same as that of Embodiment 2, the difference is that in this embodiment, the length of the plunger 723 is shorter , when the movable part 72 is in the first position, only part of the pressure relief hole 711 is filled by the plunger 723, so the movable part 72 can be lifted up for a short distance to make the pressure relief hole 711 discharge high-temperature and high-pressure steam. In addition, the end of the plunger 723 is provided with a chamfer, so when the movable part 72 moves from the second position to the first position, the plunger 723 can enter the pressure relief hole 711 relatively easily, preventing the plunger 723 from being stuck in the pressure relief hole. Outside hole 711, sealing cannot be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com