Heat-resistant steel hand welding rod for ultra-supercritical CB2 steel and preparation method thereof

An ultra-supercritical, welding rod technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problem of uneven composition of hand welding rods, and achieve the effects of good welding process performance, stable performance, and uniform welding seam composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

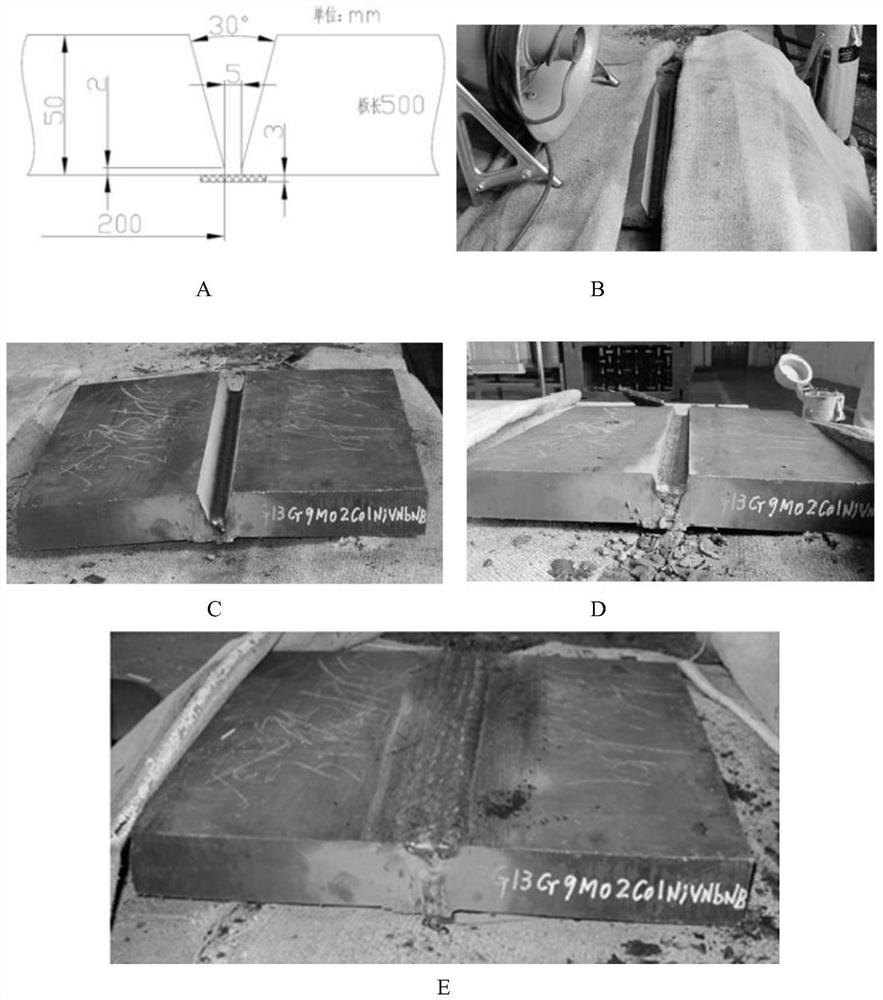

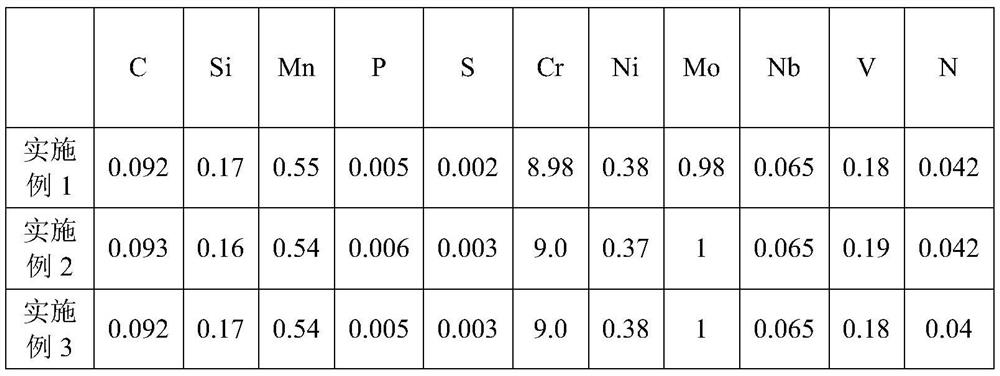

[0074] The composition of the special alloy core wire used in each embodiment of the heat-resistant steel hand electrode for ultra-supercritical CB2 steel in the present invention is shown in Table 1.

[0075] Table 1: (weight percentage)

[0076]

[0077] The flux formulation of the heat-resistant steel hand electrode for ultra-supercritical CB2 steel in each embodiment of the present invention is as shown in table 2

[0078] Table 2: (weight percentage)

[0079]

[0080]

[0081] The heat-resistant steel hand electrode for ultra-supercritical CB2 steel manufactured by the above-mentioned method in table 3, its deposited metal composition is as shown in table 3 below: (wt%)

[0082] Table 3: (weight percentage)

[0083]

[0084] The powder is weighed in proportion and mixed evenly, and then add water glass binder whose weight is 20% of the total weight of the drug skin component to carry out wet mixing and stir evenly, then press the cake, send it into the coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com