Preparation method of thermoelectric material of skutterudite

A thermoelectric material and skutterudite technology, which is applied in the field of rapid preparation of filled skutterudite thermoelectric materials to achieve the effects of shortening the preparation period, cheap performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

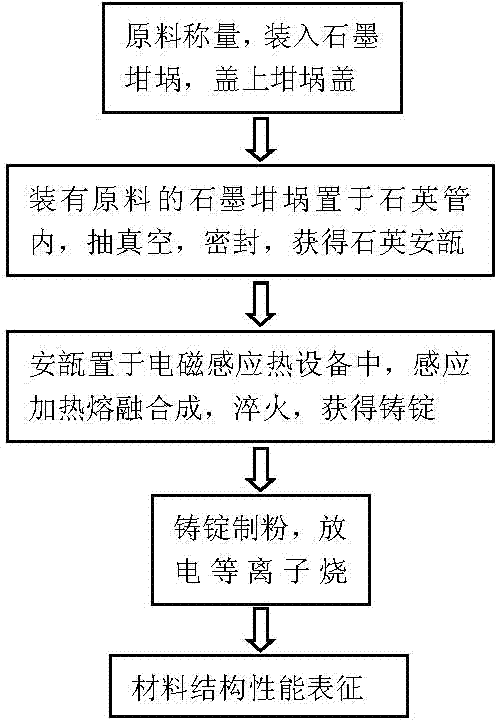

[0025] The invention provides a rapid preparation method of skutterudite thermoelectric material, comprising the following main steps:

[0026] (1) Weigh the raw material of skutterudite material, place it in a high-purity graphite crucible, and cover the crucible lid;

[0027] (2) Place the crucible in the quartz tube, vacuumize and seal it to form a quartz ampoule;

[0028] (3) The quartz ampoule is heated by induction, and the raw materials are melted to form a melt uniformly mixed in liquid phase;

[0029] (4) quenching the melt to form an ingot;

[0030] (5) The ingot is pulverized and sintered to obtain a dense skutterudite block thermoelectric material.

[0031] The raw material is placed in a high-purity graphite crucible and covered with a crucible lid to avoid Sb loss and ensure controllable composition; induction melting plus quenching can quickly obtain ingots with fine structure; spark plasma sintering, powder reaction quickly forms skutterudite, saving Anneali...

Embodiment 1

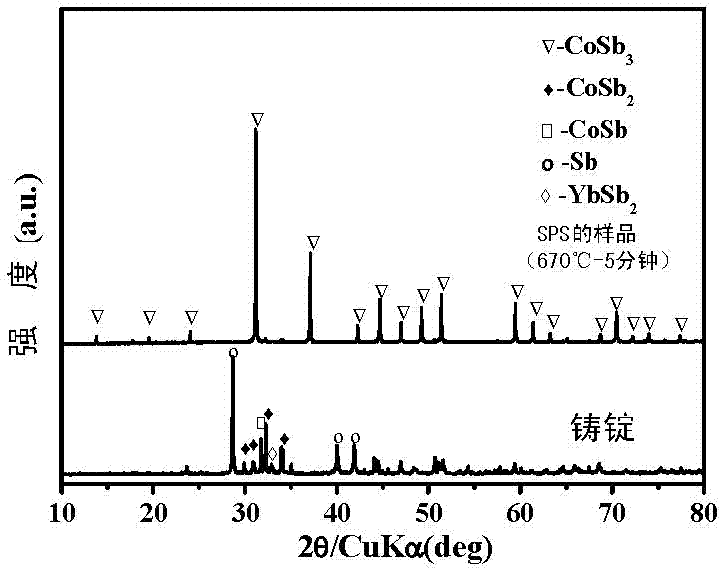

[0049] Yttrium-filled skutterudite (Yb 0.3 co 4 Sb 12 ) rapid preparation method of thermoelectric material, its technological process is as follows figure 1 As shown, the specific steps are as follows:

[0050] (1) Using high-purity granular Co, Sb and Yb as raw materials, according to the chemical formula Yb 0.3 co 4 Sb 12.1 Weighing, the total weight of the raw materials is 20 grams; the weighing raw materials are put into the graphite crucible, and the crucible lid is covered; the crucible and the crucible lid are tightly matched to ensure that the Sb vapor does not escape from the crucible during the melting and synthesis of raw materials;

[0051] (2) The graphite crucible with raw materials is placed in the quartz tube, vacuumized, filled with argon, vacuumized, repeated 3 times, and the quartz tube is sealed to obtain a quartz ampoule;

[0052] (3) Place the above-mentioned quartz ampoule in the center of the induction coil of the electromagnetic induction heatin...

Embodiment 2

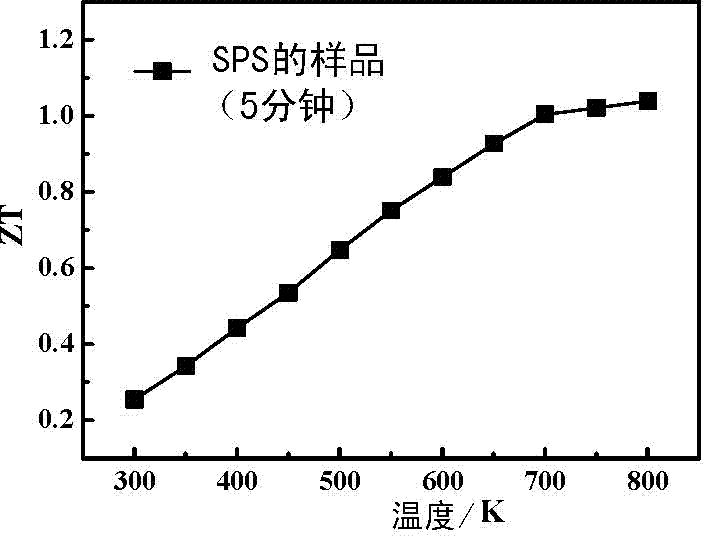

[0056] Other steps are the same as in Example 1, the sintering holding time is 15 minutes, and a dense filled skutterudite material is obtained, and the ZT value of the material is 1.15, such as Figure 4 Shown; The extension of the sintering holding time makes the ZT value of the skutterudite material further increased (10%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com