Electrode and packaging material for skutterudite thermoelectric unicouple component and step method connection technology

A technology of packaging materials and thermoelectric materials, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric devices using only the Peltier or Seebeck effect, etc., which can solve the problems of deteriorating thermoelectric performance, lack of volatile elements, and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

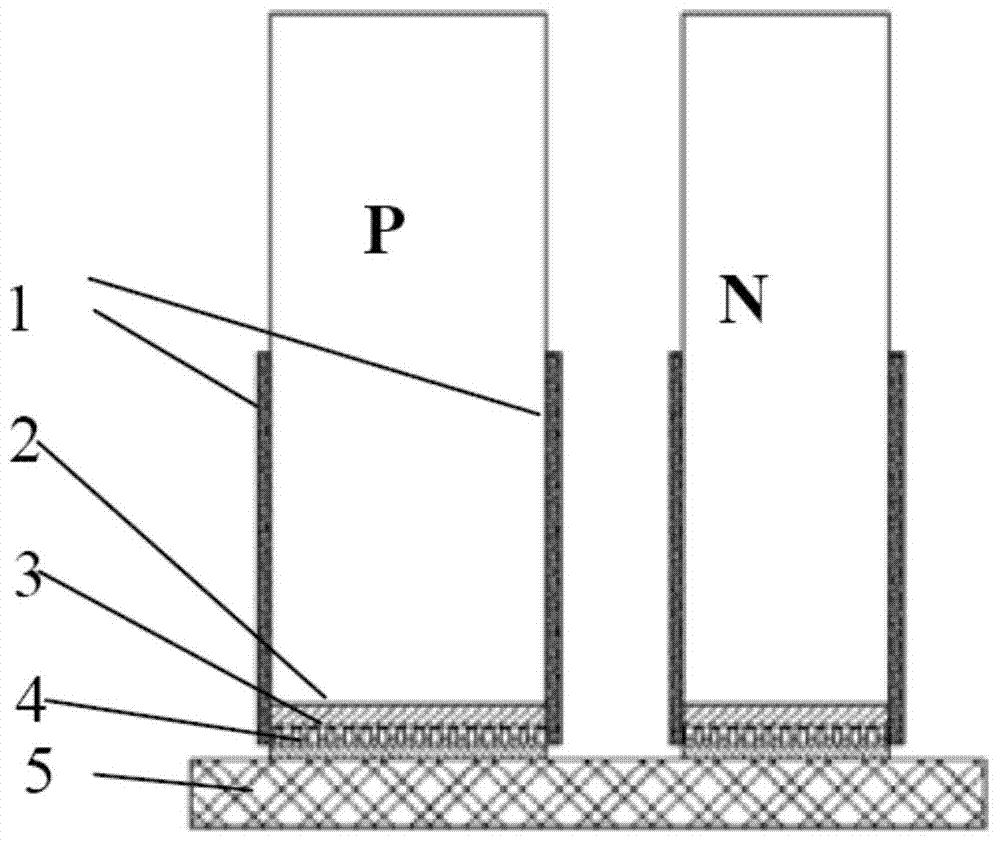

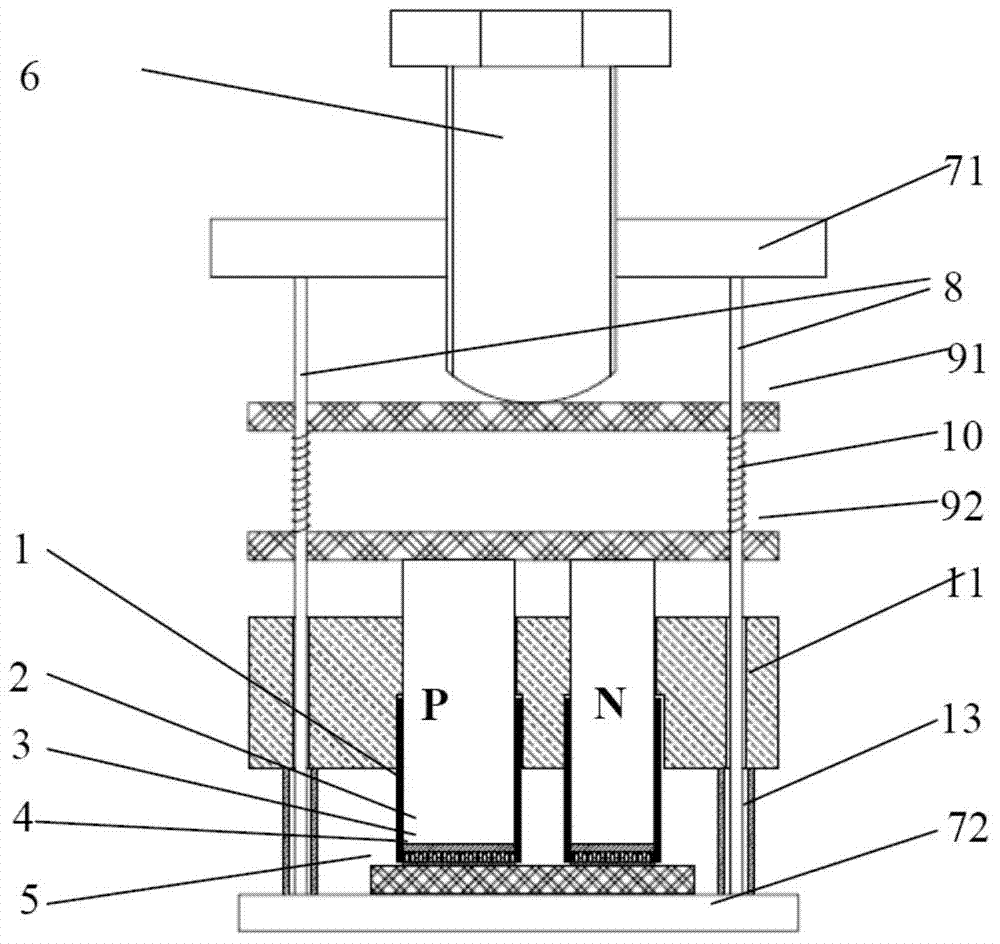

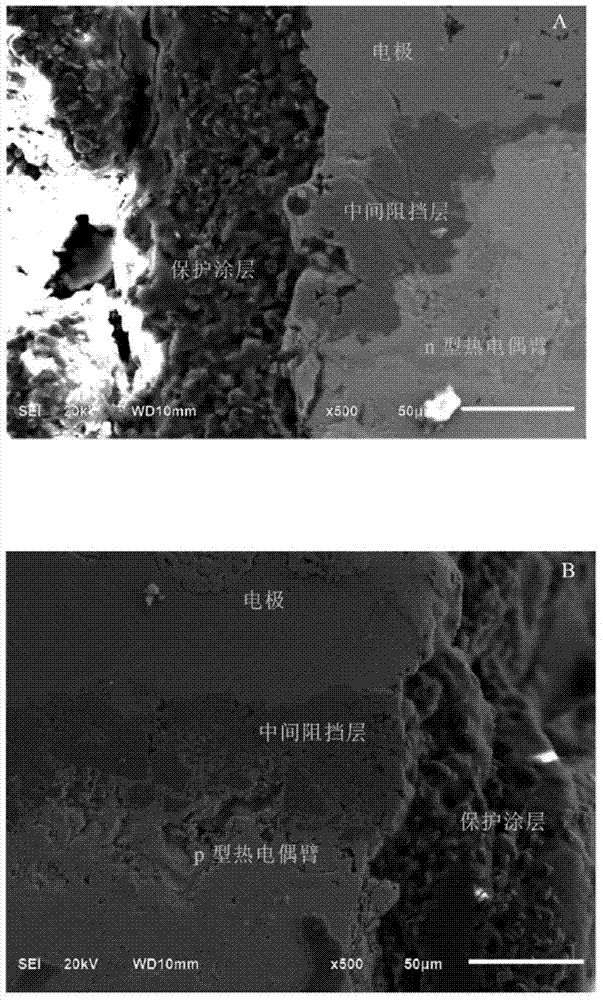

[0047] The present invention also provides a novel method for preparing a skutterudite thermoelectric monocouple element. The method has the advantage of realizing the connection between the P / N thermoelectric material and the electrode while connecting the monocouple, and completing the formation of the protective coating. preparation. The method has the characteristics of high production efficiency, high yield and low cost, and is suitable for large-scale production. First, use spark plasma sintering (SPS) or hot-press furnace to densify the P / N-type skutterudite powder material separately to obtain a bulk material, which includes a barrier layer added at the high-temperature end, and then undergoes electroplating or electroless plating Or magnetron sputtering or plasma spraying and other methods to prepare an enhanced bonding layer Ni or Cu layer on the barrier layer, the purpose of this enhanced bonding layer is to more easily realize the brazing welding with the connectin...

Embodiment approach

[0116] A preparation method for connecting an electrode and a packaging material to a thermoelectric monocouple element in one step, the preparation steps of which are as follows:

[0117] Sintering in square or circular molds to obtain P / N skutterudite thermoelectric blocks by spark plasma sintering (SPS) or hot pressing sintering;

[0118] The feature of the skutterudite block is that its high temperature end has a barrier layer and an enhanced bonding layer, the barrier layer includes Ti powder or Ti foil, Mo or TiAl mixed powder and alloy, and the enhanced bonding layer can be Ni foil or Ni powder or Cu Foil or Cu powder, the barrier layer and the enhanced bonding layer can be directly sintered, and can also be used after sintering by plasma spraying, arc spraying, thermal spraying, electroplating, electroless plating, magnetron sputtering, electron beam evaporation and other methods preparation.

[0119] The skutterudite block is cut by wire to obtain blocks of target si...

Embodiment 1

[0150] First, the SPS bulk is sintered

[0151] The Ni foil (0.1mm) 3 of the reinforcing bonding layer, the Ti powder of the barrier layer 2, and the P / N skutterudite powder are put into the mold in turn for SPS sintering to obtain the skutterudite block material.

[0152] Then, cut the P type with a size of 7*4*13mm and the N type with a size of 7*3*13mm by wire cutting, and then perform degreasing treatment, use a detergent to ultrasonic for 10 minutes, and then clean with alcohol for 10 minutes. Then carry out drying treatment, the treatment condition is 80°C, 30min. The connection electrode 5, the solder (solder sheet) 4, and the welding joint surface of the skutterudite block are respectively treated for the purpose of removing the surface oxide layer and roughening it, so as to enhance the welding bonding force. Preferably, use 200# sandpaper for grinding, and then clean the surface.

[0153] Secondly, coating 1 is applied to the side of the high-temperature end (that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com