Preparation method and application of high lithium salt concentration aqueous polyurethane ionomer

A water-based polyurethane, salt concentration technology, applied in electrochemical generators, electrical components, circuits, etc., can solve problems such as poor compatibility between organic groups and metal lithium, low conductivity of polymer electrolytes, and impact on use value, etc. Achieve the effect of high electrical conductivity, excellent comprehensive performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

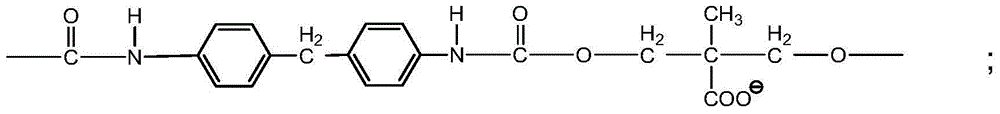

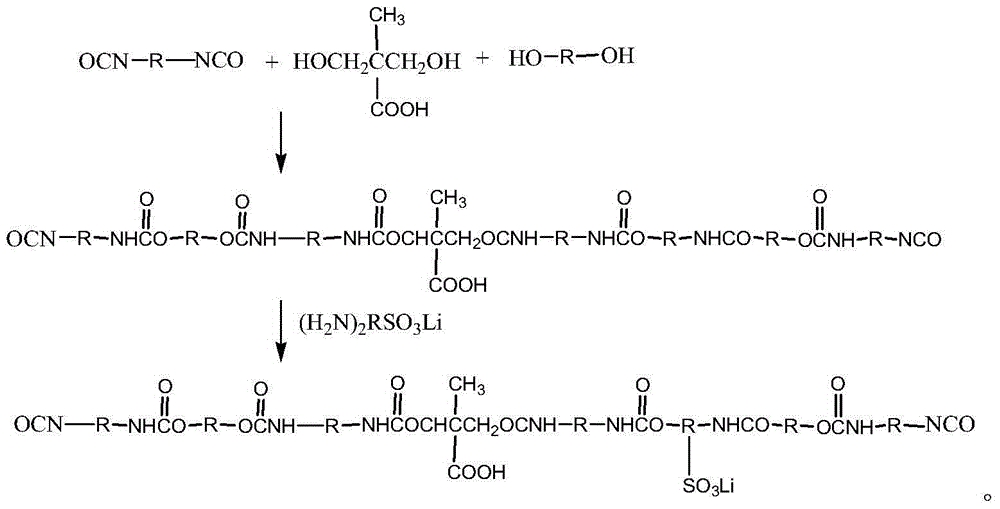

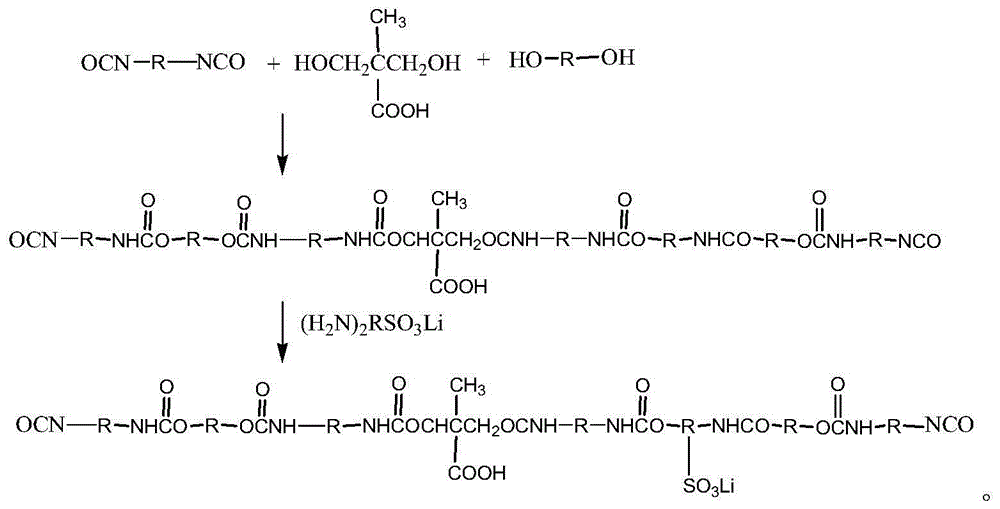

Image

Examples

Embodiment 1

[0023] The present embodiment provides a kind of preparation method of the aqueous polyurethane ionomer of high lithium salt concentration, and it comprises the steps:

[0024] S1. In a 500ml four-neck flask equipped with a stirring thermometer, reflux condenser and feeder, add PEG (2000) and PTMG (2000) with a mass ratio of 1:1 according to the ratio of NCO / OH to 1.2. Dehydration at room temperature for 2 hours, cooling to 80°C, adding DMPA with a total mass of 4% of the PEG and PTEG, vacuum dehydration for 1 hour, cooling to 60°C to obtain a prepolymer, adding 3% of the prepolymer mass to it Solvent NMP, and add IPDI of 8% by mass of the prepolymer and T-12 of 0.03% by mass of the prepolymer, slowly raise the temperature to 85°C, and continue the reaction for 3h until the NCO value reaches the theoretical value, and the NCO value It can be determined by the di-n-butylamine method to obtain an NCO-terminated waterborne polyurethane prepolymer;

[0025] S2. Add lithium disulf...

Embodiment 2

[0028] The present embodiment provides a kind of preparation method of the aqueous polyurethane ionomer of high lithium salt concentration, and it comprises the steps:

[0029] S1. In a 500ml four-neck flask equipped with a stirring thermometer, reflux condenser and feeder, add PEG (2000) and PTMG (2000) with a mass ratio of 2:1 according to the NCO / OH ratio of 1.4. Dehydration at room temperature for 3 hours, cooling to 85°C, adding DMPA with a total mass of 3.5% of the PEG and PTEG, vacuum dehydration for 1.5 hours, cooling to 65°C to obtain a prepolymer, adding 5% of the mass of the prepolymer to it solvent NMP, and add 10% of the prepolymer mass of IPDI and 0.05% of the prepolymer mass of T-12, slowly heat up to 90 ° C, and continue the reaction for 4 hours until the NCO value reaches the theoretical value, the NCO Value can be measured by the di-n-butylamine method, promptly obtains the aqueous polyurethane prepolymer of NCO termination;

[0030] S2. Add lithium disulfam...

Embodiment 3

[0033] The present embodiment provides the preparation method of the aqueous polyurethane ionomer of a kind of high lithium salt concentration of high lithium salt concentration, and it comprises the steps:

[0034] S1. In a 500ml four-neck flask equipped with a stirring thermometer, reflux condenser and feeder, add PEG (2000) and PTMG (2000) with a mass ratio of 1.5:1 according to the NCO / OH ratio of 1.8, at 120°C Dehydration at room temperature for 4 hours, after cooling to 75°C, adding DMPA with a total mass of 5% of the PEG and PTEG, vacuum dehydration for 2 hours, cooling to 70°C to obtain a prepolymer, adding 7% of the mass of the prepolymer to it Solvent NMP, and add 12% of the prepolymer mass of IPDI and 0.06% of the prepolymer mass of T-12, slowly raise the temperature to 90°C, and continue the reaction for 4.5h until the NCO value reaches the theoretical value, the NCO Value can be measured by the di-n-butylamine method, promptly obtains the aqueous polyurethane prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com