Method for preparing lanthanum-zirconium oxide La2Zr2O7 buffer layer thin film of high-temperature superconducting coating conductor on biaxially textured NiW alloy substrate

A technology of coated conductors and high-temperature superconductors, which is applied in the manufacture/processing of superconductor devices, can solve the problems of high prices and restrictions on the development of practical strips, and achieve reduced production costs, smooth coatings, and simple production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first specific embodiment of the present invention is a method for preparing a high-temperature superconducting coating conductor La on a biaxially textured NiW alloy substrate. 2 Zr 2 o 7 The method for buffer layer thin film, its step is:

[0029] a, preparation of anhydrous solution: equal to the ratio of 1:1 by the ion number ratio of lanthanum and zirconium, get lanthanum nitrate (La(NO 3 ) 3 .6H 2 O) and zirconium nitrate (Zr(NO 3 ) 4 .5H 2 O), be dissolved in ethylene glycol methyl ether, form anhydrous solution;

[0030] b. Colloid preparation: Add polyethylene glycol-20000 to the anhydrous solution of step a to form a colloid;

[0031] c. Colloid coating and drying: coating the colloid prepared in step b on the biaxially textured NiW alloy substrate;

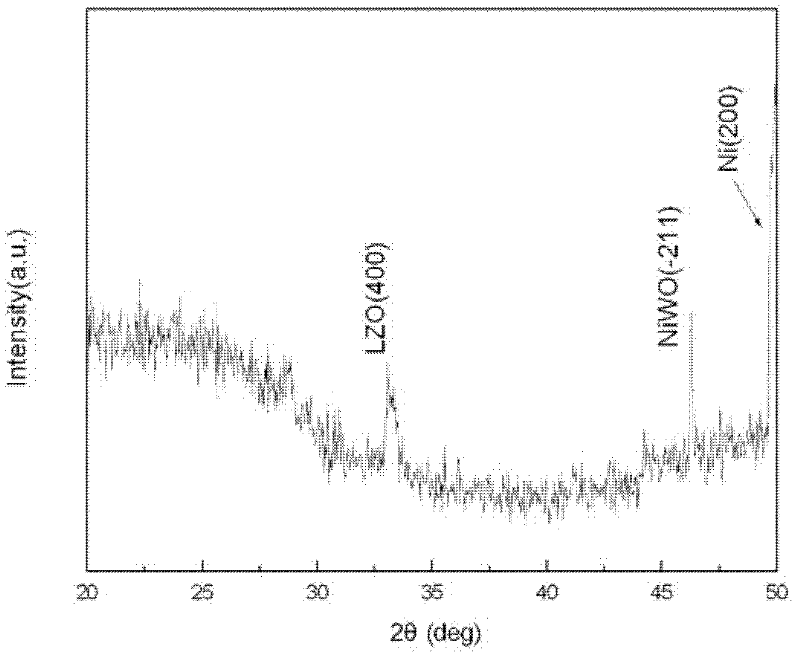

[0032] d, thermal decomposition treatment: the substrate coated with colloid is placed in a sintering furnace, and 2 5% H by volume 2 -In an Ar mixed gas atmosphere, raise the furnace temperature f...

Embodiment 2

[0039] The preparation method of this example consists of the following steps in turn:

[0040] a, preparation of anhydrous solution: equal to the ratio of 1:1 by the ion number ratio of lanthanum and zirconium, get lanthanum nitrate (La(NO 3 ) 3 .6H 2 O) and zirconium nitrate (Zr(NO 3 ) 4 .5H 2 O), be dissolved in ethylene glycol methyl ether, form anhydrous solution;

[0041] b. Colloid preparation: Add polyethylene glycol-20000 to the anhydrous solution of step a to form a colloid;

[0042] c. Colloid coating and drying: coating the colloid prepared in step b on the biaxially textured NiW alloy substrate;

[0043] d, thermal decomposition treatment: the substrate coated with colloid is placed in a sintering furnace, and 2 5% H by volume 2 -In an Ar mixed gas atmosphere, raise the furnace temperature from room temperature to 400°C at a rate of 0.7°C / min, then to 670°C at a rate of 1.2°C / min and keep it warm for 0.5 hours, then let the furnace cool down to room temper...

Embodiment 3

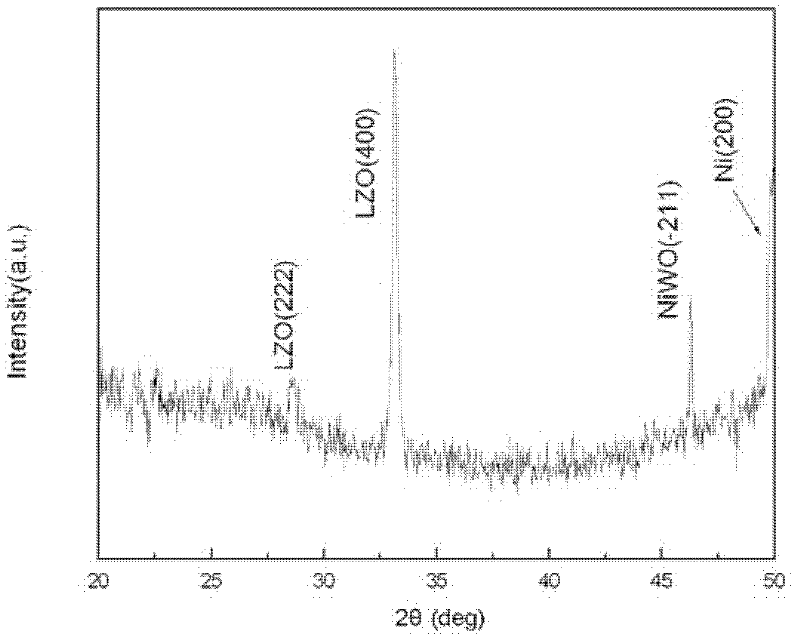

[0050] The preparation method of this example consists of the following steps in turn:

[0051] a, preparation of anhydrous solution: equal to the ratio of 1:1 by the ion number ratio of lanthanum and zirconium, get lanthanum nitrate (La(NO 3 ) 3 .6H 2 O) and zirconium nitrate (Zr(NO 3 ) 4 .5H 2 O), be dissolved in ethylene glycol methyl ether, form anhydrous solution;

[0052] b. Colloid preparation: Add polyethylene glycol-20000 to the anhydrous solution of step a to form a colloid;

[0053] c. Colloid coating and drying: coating the colloid prepared in step b on the biaxially textured NiW alloy substrate;

[0054] d, thermal decomposition treatment: the substrate coated with colloid is placed in a sintering furnace, and 2 5% H by volume 2 -In an Ar mixed gas atmosphere, the furnace temperature was raised from room temperature to 420°C at a rate of 0.7°C / min, and then raised to 700°C at a rate of 1.4°C / min for 0.5 hours, and then the furnace was allowed to cool down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com