Method for preparing superconducting yttrium barium copper oxide (YBCO) twisted wire through 3D printing

A technology of yttrium barium copper oxide and 3D printing, which is applied in superconducting devices, superconducting/high-conducting conductors, chemical instruments and methods, etc., can solve problems such as no related research on 3D printing technology, and achieve huge scientific research and commercial value , Reduce production cost, reduce the effect of phase forming treatment process and difficulty of twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

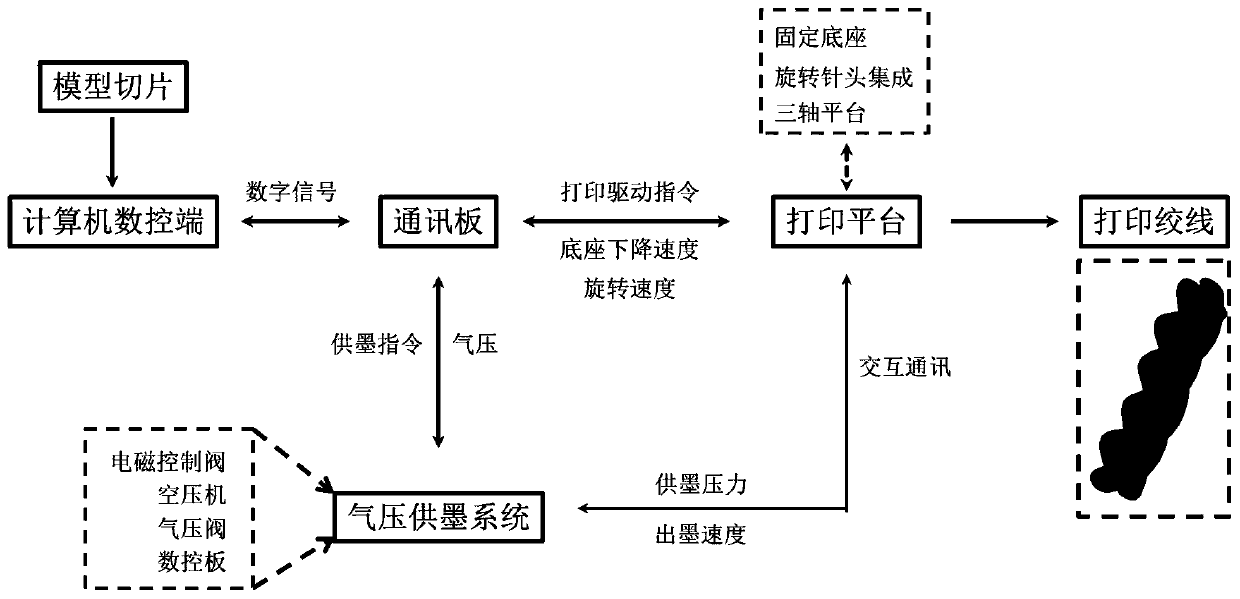

[0030] The invention discloses a method for preparing yttrium barium copper oxide superconducting stranded wire based on 3D printing:

[0031] Technical solutions:

[0032] 1. Preparation of superconducting powder precursor: The main printing material is YBCO superconducting material or mixed powder (copper oxide, yttrium oxide, barium carbonate) that can be sintered to form a superconducting phase. The printing main material is mechanically pulverized or jet pulverized or ball milled to obtain a printing powder with a particle size of 100-300nm.

[0033] 2. Preparation of printing paste: add the ground superconducting powder precursor to a suitable ratio of polymer binder and lubricant mixture to form a direct writing molding paste. The polymer binder used here can be polyethylene glycol (PVA), polyvinylpyrrolidone (PVP), polyvinyl butyral (PVB), sodium carboxymethylcellulose (CMC), etc., and the lubricating oil can be Mineral lubricants can also be used vegetable lubricant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com