La-Fe based magnetic refrigeration composite material and preparation method thereof

A technology of magnetic refrigeration materials and composite materials, which is applied in the fields of magnetic materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of material pulverization, high energy consumption, poor impact resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

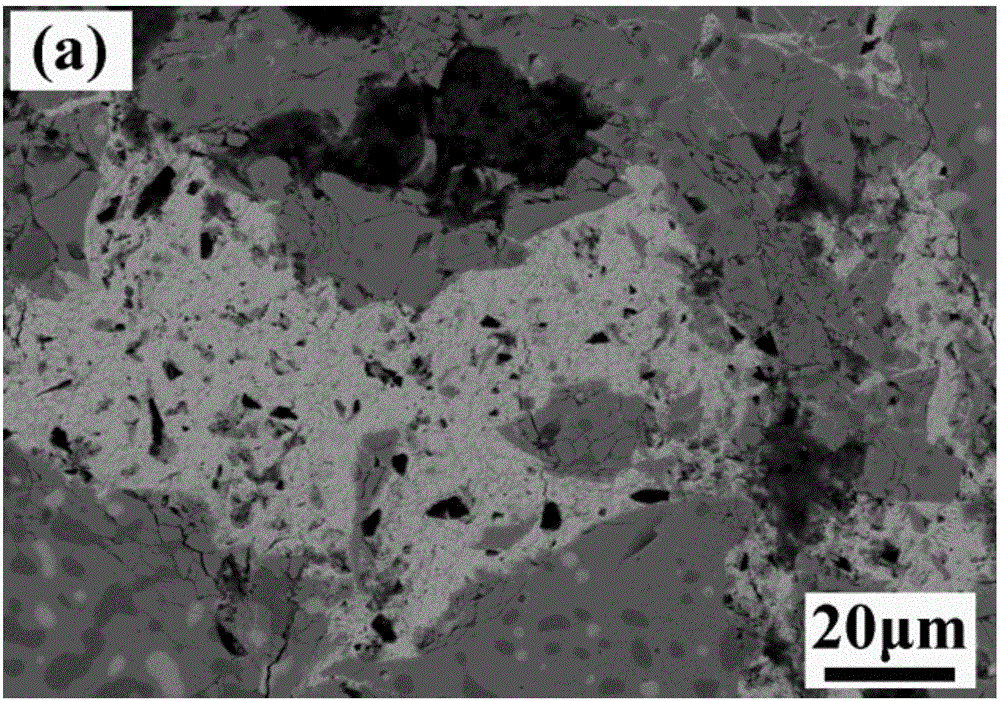

Embodiment 1

[0032]A kind of La-Fe base magnetic refrigeration composite material, its preparation method is as follows:

[0033] Step 1: Calculate based on the total mass of 1.4g, where 10% of the metal tin is 0.14g, and the rest is La with good phase formation 0.8 Ce 0.2 (Fe 0.95 co 0.05 ) 11.8 Si 1.2 The compounds are all composed of 180-250 μm coarse main phase particles, that is, the weight ratio of the fine main phase powder less than 45 μm is 0%.

[0034] Step 2: Mix the weighed materials until they are uniform. When they are uniform, the aggregation of fine powder cannot be seen with the naked eye. Then put the mixed materials into a Φ8 mold and perform pre-compacting.

[0035] Step 3: Heat the mold to 151°C at a heating rate of 10-15°C / min, pressurize to 980MPa after the temperature is stable, stop heating after holding the heat for 2 minutes, and release the pressure when the temperature cools below 100°C. The mold temperature can be demoulded when it is close to room tempe...

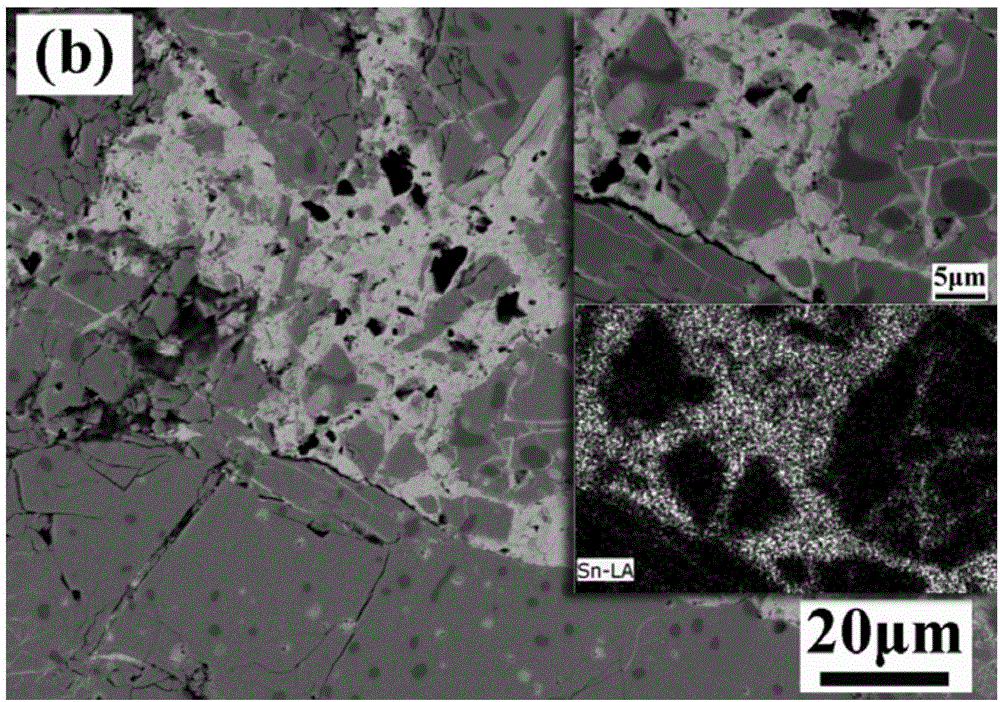

Embodiment 2

[0043] A kind of La-Fe base magnetic refrigeration composite material, its preparation method is as follows:

[0044] Step 1: Calculate based on the total mass of 1.4g, where 10% of the metal tin is 0.14g, and the rest is La with good phase formation 0.8 Ce 0.2 (Fe 0.95 co 0.05 ) 11.8 Si 1.2 The compound is composed of coarse main phase particles of 180-250 μm and fine main phase powder less than 45 μm, wherein the weight ratio of the fine main phase powder less than 45 μm is 5%.

[0045] Step 2: Mix the weighed materials until they are uniform. When they are uniform, the aggregation of fine powder cannot be seen with the naked eye. Then put the mixed materials into a Φ8 mold and perform pre-compacting.

[0046] Step 3: Heat the mold to 148°C at a heating rate of 10-15°C / min, pressurize to 950MPa after the temperature is stable, stop heating after holding the heat for 2 minutes, and release the pressure when the temperature cools below 100°C. The mold temperature can be ...

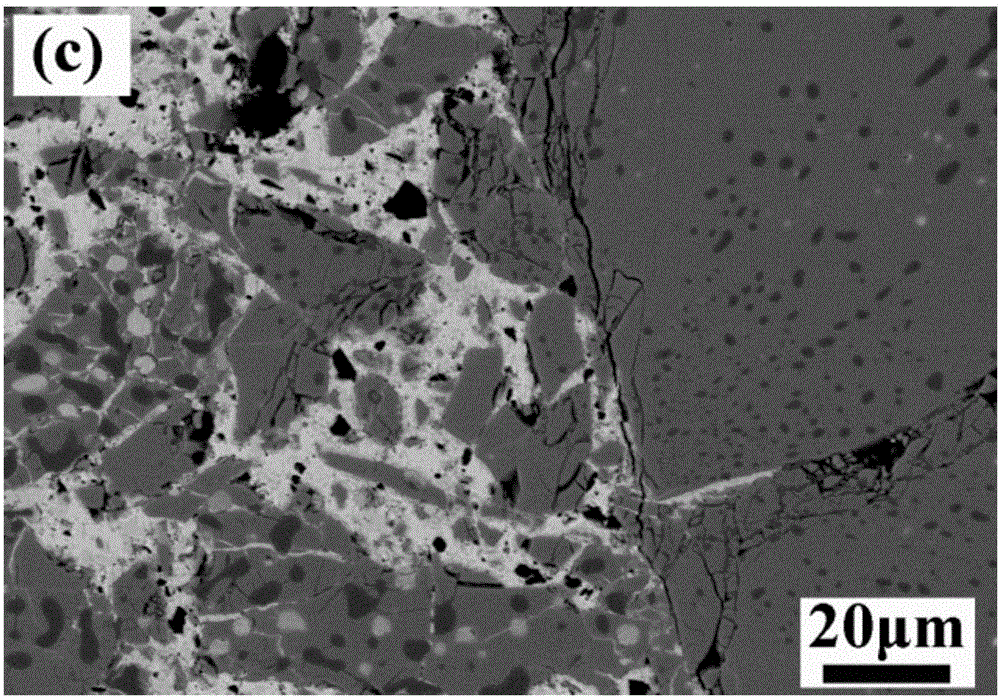

Embodiment 3

[0054] A kind of La-Fe base magnetic refrigeration composite material, its preparation method is as follows:

[0055] Step 1: Calculate based on the total mass of 1.4g, where 10% of the metal tin is 0.14g, and the rest is La with good phase formation 0.8 Ce 0.2 (Fe 0.95 co 0.05 ) 11.8 Si 1.2 The compound is composed of coarse main phase particles of 180-250 μm and fine main phase powder of less than 45 μm, wherein the weight ratio of the fine main phase powder of less than 45 μm is 10%.

[0056] Step 2: Mix the weighed materials until they are uniform. When they are uniform, the aggregation of fine powder cannot be seen with the naked eye. Then put the mixed materials into a Φ8 mold and perform pre-compacting.

[0057] Step 3: Heat the mold to 145°C at a heating rate of 10-15°C / min, pressurize to 930MPa after the temperature is stable, stop heating after holding the heat for 2 minutes, and release the pressure when the temperature cools below 100°C. The mold temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com