High-strength face-centered cubic structure medium-entropy alloy and preparation method thereof

A technology of face-centered cubic and entropy alloy, applied in the field of entropy alloy and its preparation in high-strength face-centered cubic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

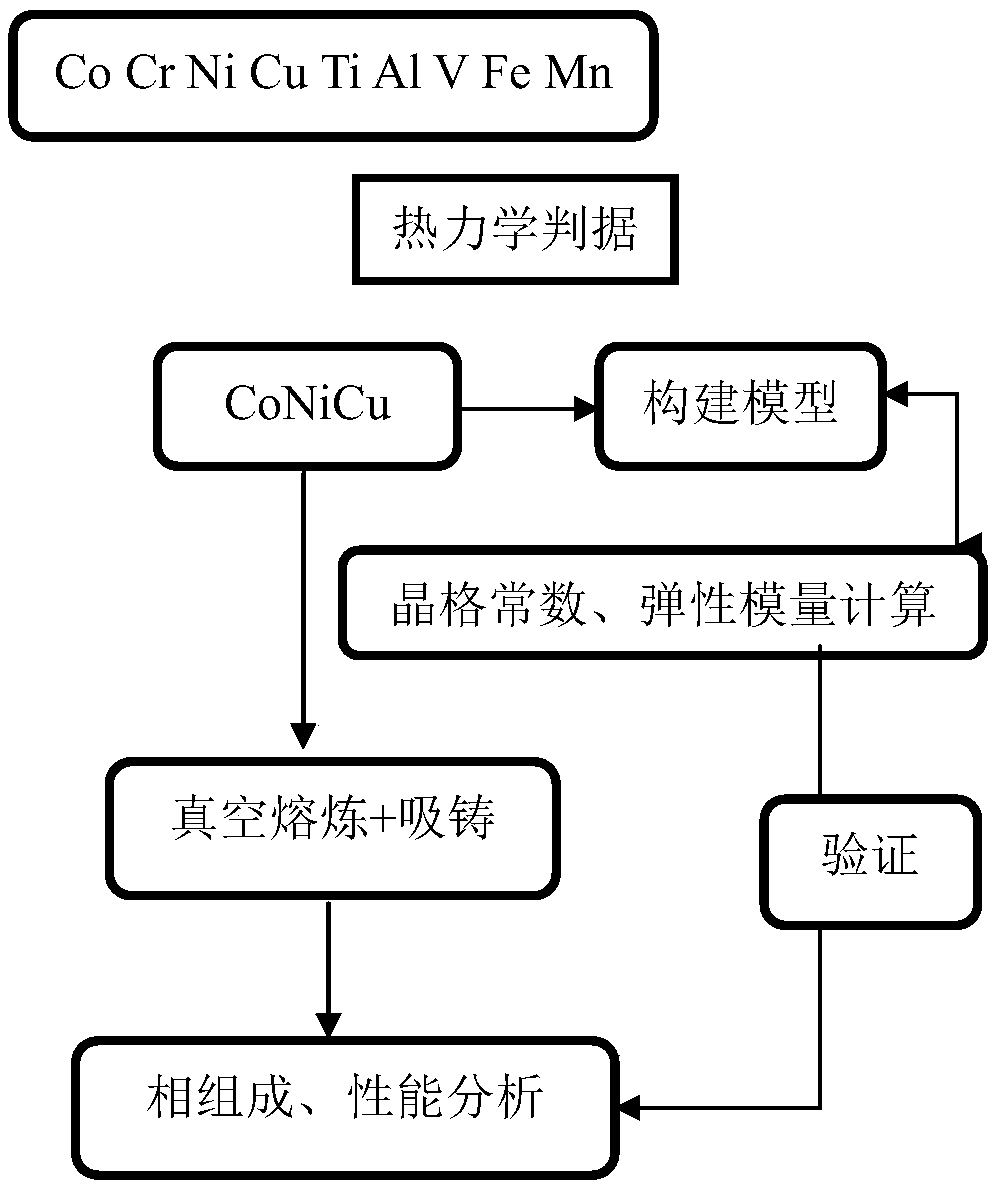

AI Technical Summary

Problems solved by technology

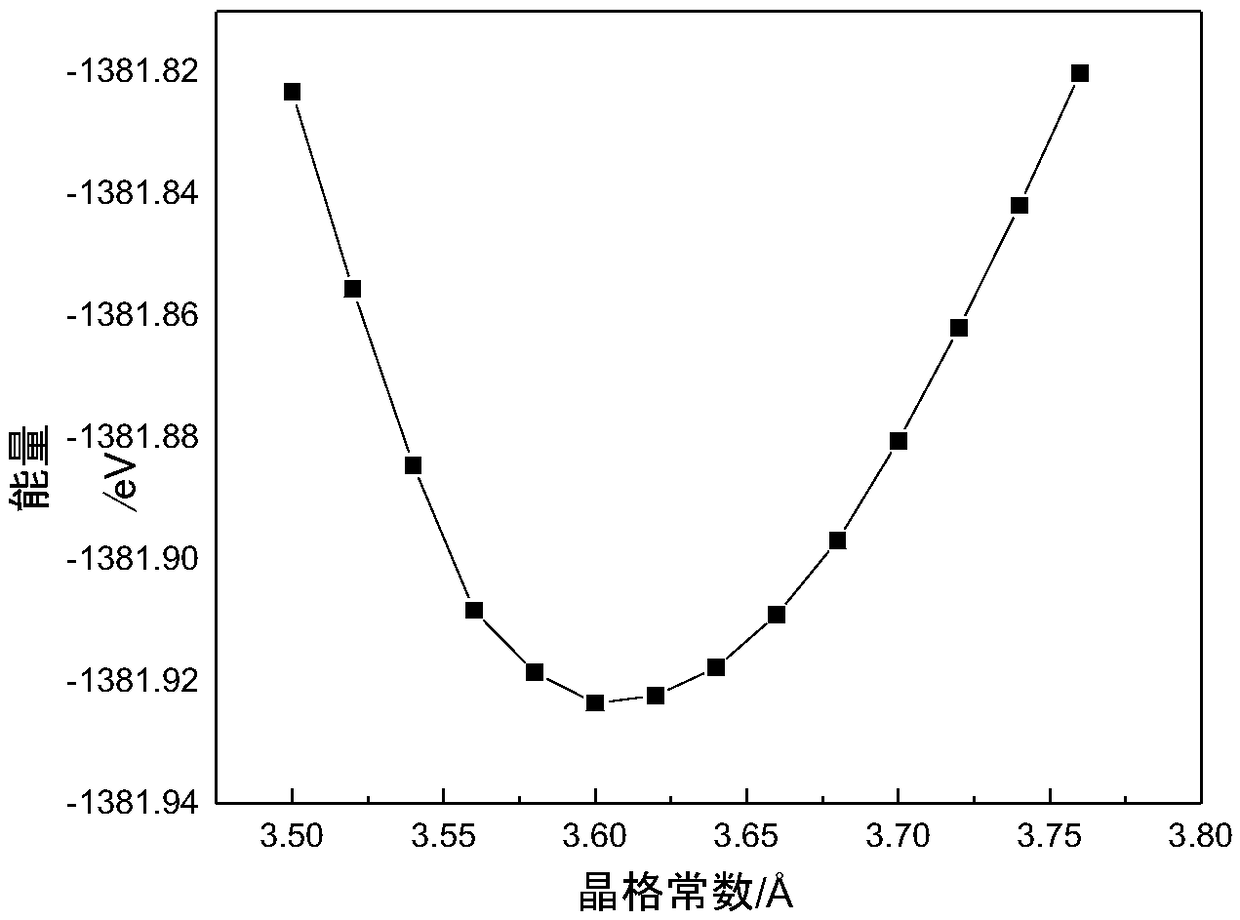

Method used

Image

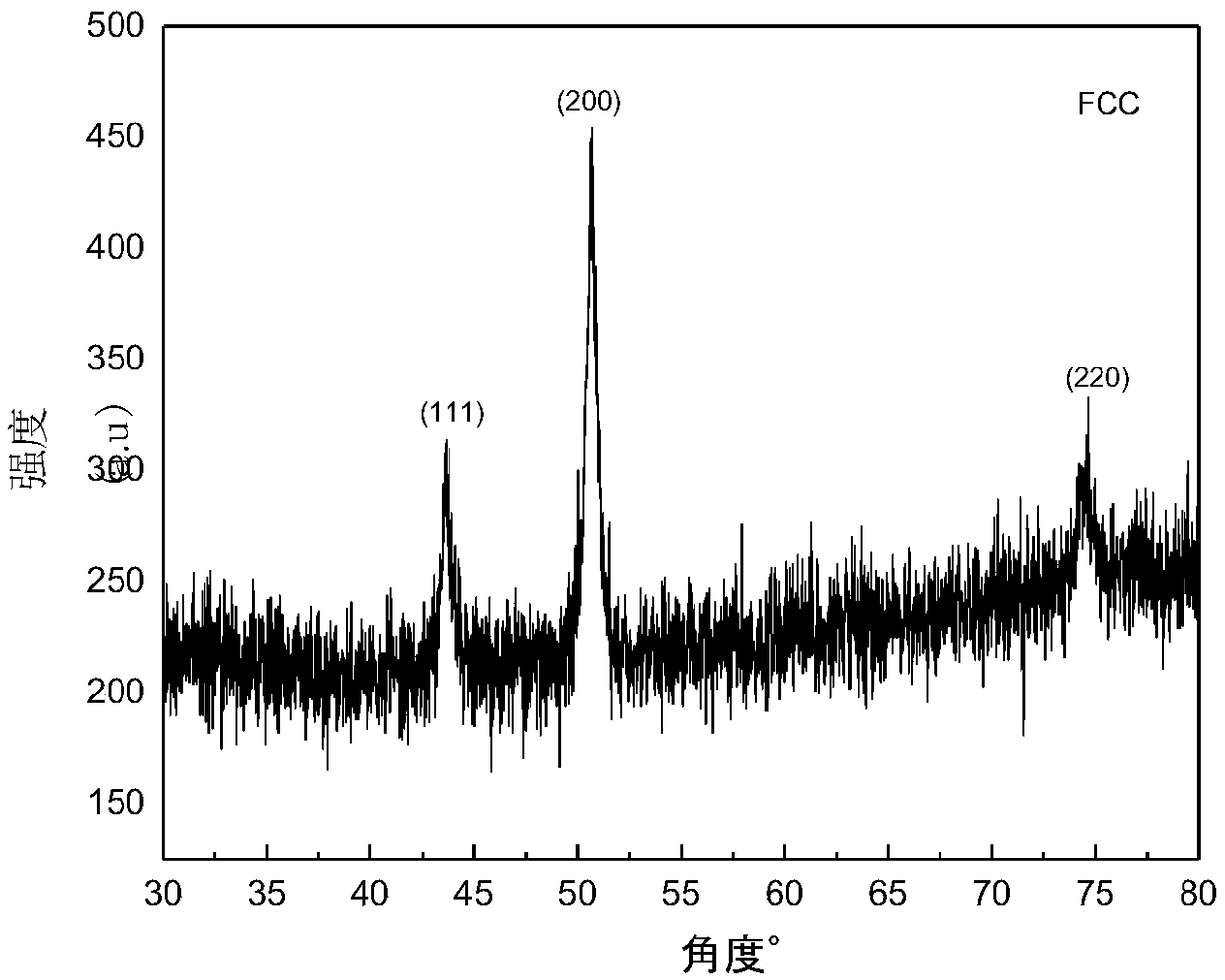

Examples

Embodiment 1

[0042] A high-strength face-centered cubic medium-entropy alloy, the alloy composition: Co: 30%, Ni: 30%, Cu: 40%, and its preparation method comprises the following steps:

[0043] Weigh 5.62g of Co ingot, 6.29g of Ni ingot, and 8.08g of Cu ingot, and mix the granular / block raw materials Co, Cu, and Ni with a purity greater than 99.99% in proportion.

[0044] 2) Put the ingredients into the vacuum melting furnace and vacuumize to 1×10 -3 Pa, then fill with argon until the pressure in the furnace reaches 0.05MPa, melting current: 200A, turn over and repeat melting for more than 5 times.

[0045] 3) Suction cast the ingot, after cooling, take out the cast rod, put it into the muffle furnace for homogenization annealing treatment, raise the temperature to 1000°C at a rate of 5°C / min, then open the furnace door, and quickly place the cast rod Put it into the furnace, wait for the temperature of the furnace to return to 1000°C, and keep it for 1 hour.

[0046] 3. Put the medium ...

Embodiment 2

[0048]A high-strength face-centered cubic medium-entropy alloy, the alloy composition: Co: 32%, Ni: 32%, Cu: 36%, and its preparation method comprises the following steps:

[0049] Weigh 5.99g of Co ingots, 6.72g of Ni ingots, and 7.27g of Cu ingots, and mix the granular / blocky raw materials Co, Cu, and Ni with a purity greater than 99.99% in proportion.

[0050] 2) Put the ingredients into the vacuum melting furnace and vacuumize to 1×10 -3 Pa, then fill with argon until the pressure in the furnace reaches 0.05MPa, melting current: 200A, turn over and repeat melting for more than 5 times.

[0051] 3) Suction-cast the ingot, after cooling, take out the cast rod, put it into the muffle furnace for homogenization annealing treatment, raise the temperature to 1000°C at a rate of 5°C / min, then open the furnace door, and quickly put the cast rod Put it into the furnace, wait for the temperature of the furnace to return to 1000°C, and keep it for 1 hour.

[0052] 3. Put the medium...

Embodiment 3

[0054] A high-strength face-centered cubic medium-entropy alloy, the alloy composition: Co: 33.3%, Cu: 33.3%, Ni: 33.3%, and its preparation method comprises the following steps:

[0055] Weigh 6.5g of Co ingots, 7.01g of Cu ingots, and 6.47g of Ni ingots, and mix the granular / blocky raw materials Co, Cu, and Ni with a purity greater than 99.99% in proportion.

[0056] 2) Put the ingredients into the vacuum melting furnace and vacuumize to 1×10 -3 Pa, then fill with argon until the pressure in the furnace reaches 0.05MPa, melting current: 200A, turn over and repeat melting for more than 5 times.

[0057] 3) Suction-cast the ingot, after cooling, take out the cast rod, put it into the muffle furnace for homogenization annealing treatment, raise the temperature to 1000°C at a rate of 5°C / min, then open the furnace door, and quickly put the cast rod Put it into the furnace, wait for the temperature of the furnace to return to 1000°C, and keep it for 1 hour.

[0058] 3. Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com