Method for improving luminescent intensity and stability of synthesized YAG (yttrium aluminum garnet):Ce fluorescent powder

A technology of luminous intensity and stability, applied in the field of rare earth luminescent materials, can solve the problems of severe color coordinate drift, low LED luminous efficiency, poor dispersion, etc., to achieve improved luminous intensity and stability, good luminous effect, dispersion and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

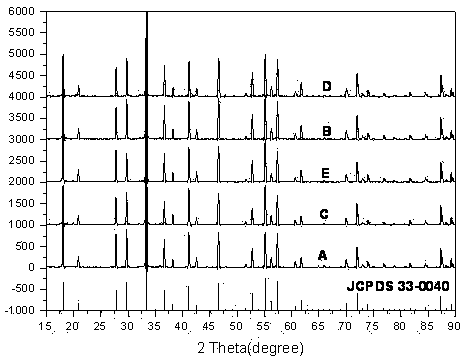

[0027] Weigh Y according to the molar ratio Y:Al:Ce=2.94:5:0.06 2 o 3 , Al(OH) 3 , CeO 2 ,, the above are all analytically pure, add an appropriate amount of NaF flux, mix the above raw materials evenly, transfer them to an alumina crucible for compaction and place them in a high-temperature reaction furnace for high-temperature calcination, and introduce reducing gas at a temperature of 1600 ° C. Time 6h. After cooling to room temperature, take out the sample and grind it, and dry-sieve it through a 100-mesh sieve. For the XRD characterization of the sample, see figure 1 Sample A. Wash the obtained powder with hot water, then pass through a 200-mesh wet sieve, and put the sample obtained by the wet sieve into an oven at 100°C to dry to obtain a water-washed fluorescent raw powder for future use.

Embodiment 2

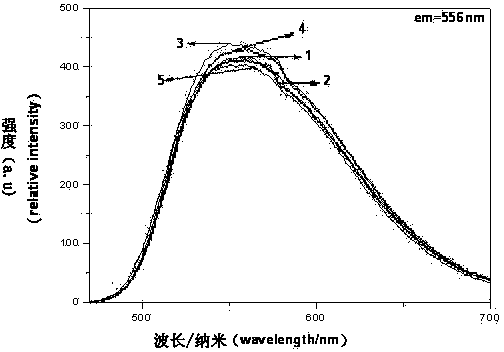

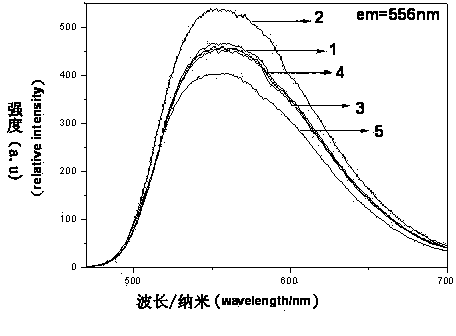

[0029] Take the washed fluorescent raw powder obtained in Example 1, put it in a tube furnace for secondary reduction with hydrogen-nitrogen mixed gas (5%-95%), the temperature is 1450°C, the holding time is 4h, and take it out after cooling to room temperature The sample is ground, and the fluorescence emission spectrum of the obtained sample is shown in figure 2 Sample 1, the XRD characterization of the sample is shown in figure 1 For sample B, its fluorescence intensity is 1.03 times that of the factory YAG product.

Embodiment 3

[0031] Take the washed fluorescent raw powder obtained in Example 1, add 8‰NH4HF2 and place it in a tube furnace for secondary reduction with hydrogen-nitrogen mixed gas (5%-95%), the temperature is 1450°C, the holding time is 4h, cool After reaching room temperature, the sample was taken out for grinding, and the fluorescence emission spectrum of the obtained sample was shown in figure 2 Sample 2, its fluorescence intensity is 1.02 times that of factory YAG products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com