Fluorescent powder capable of being effectively excited by blue light and preparation method thereof

A yellow phosphor, phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of not being able to improve the color rendering index and color temperature well, and achieve a wide range of excitation wavelengths, good luminescence effect, and luminous intensity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

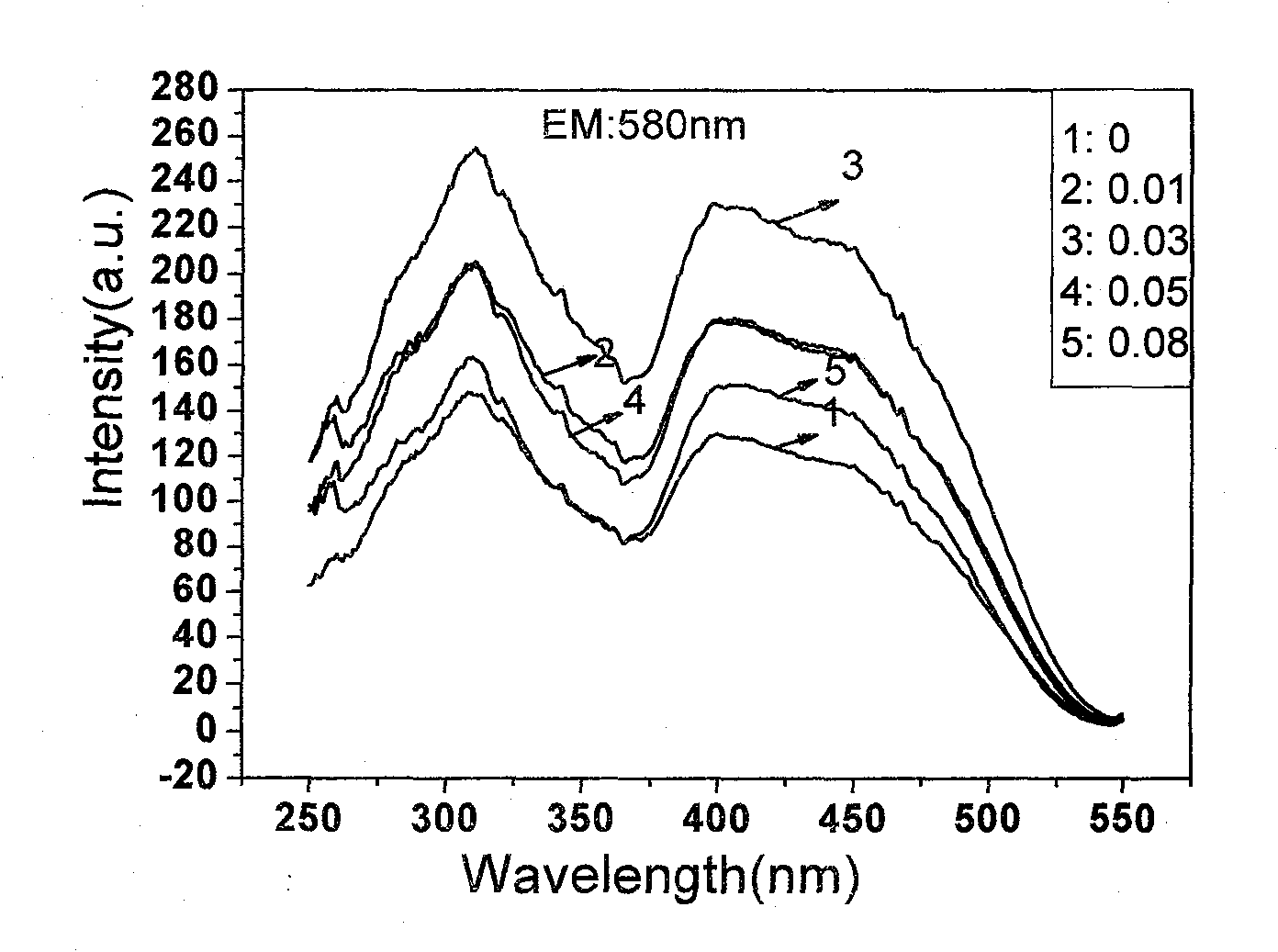

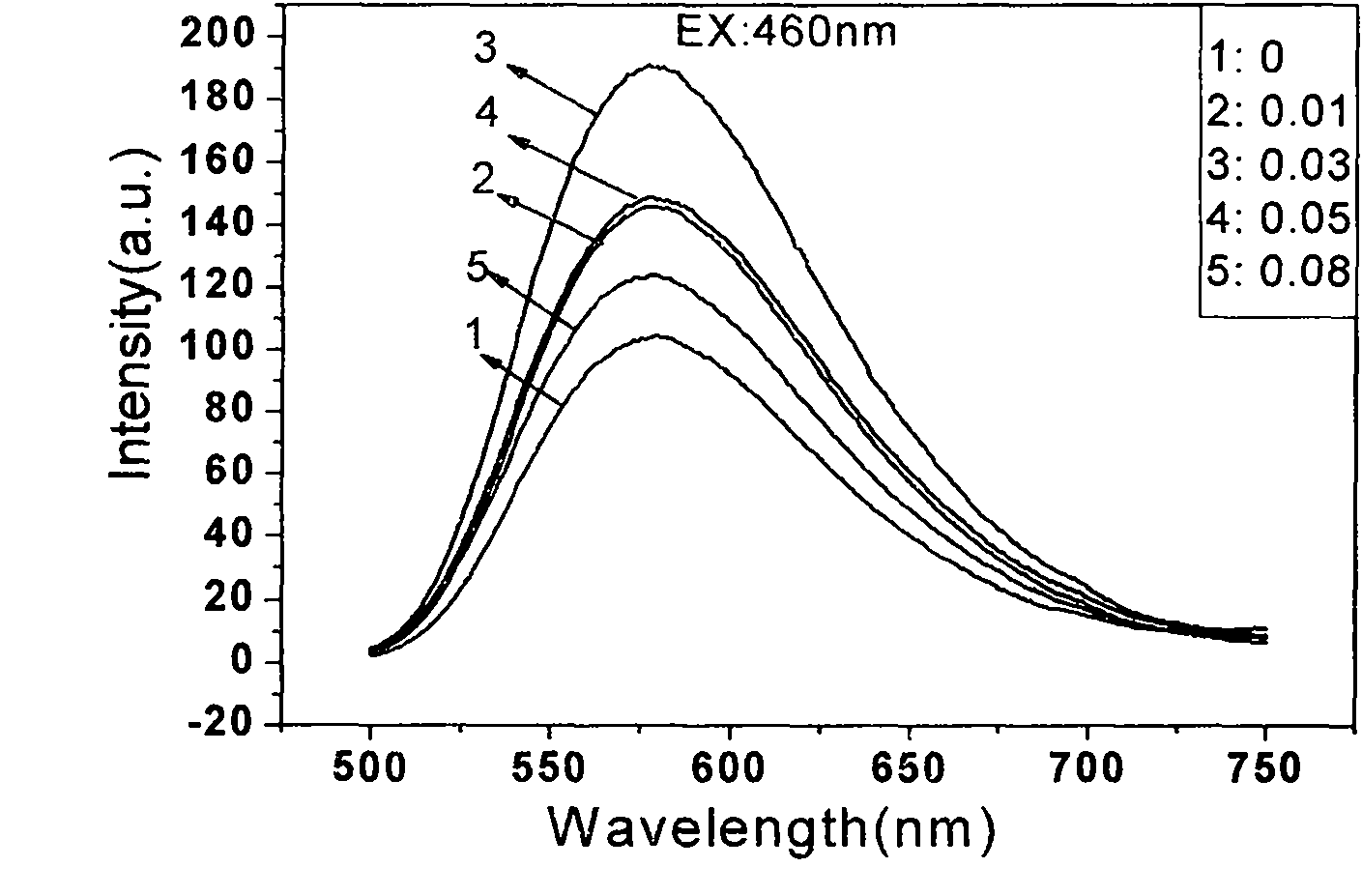

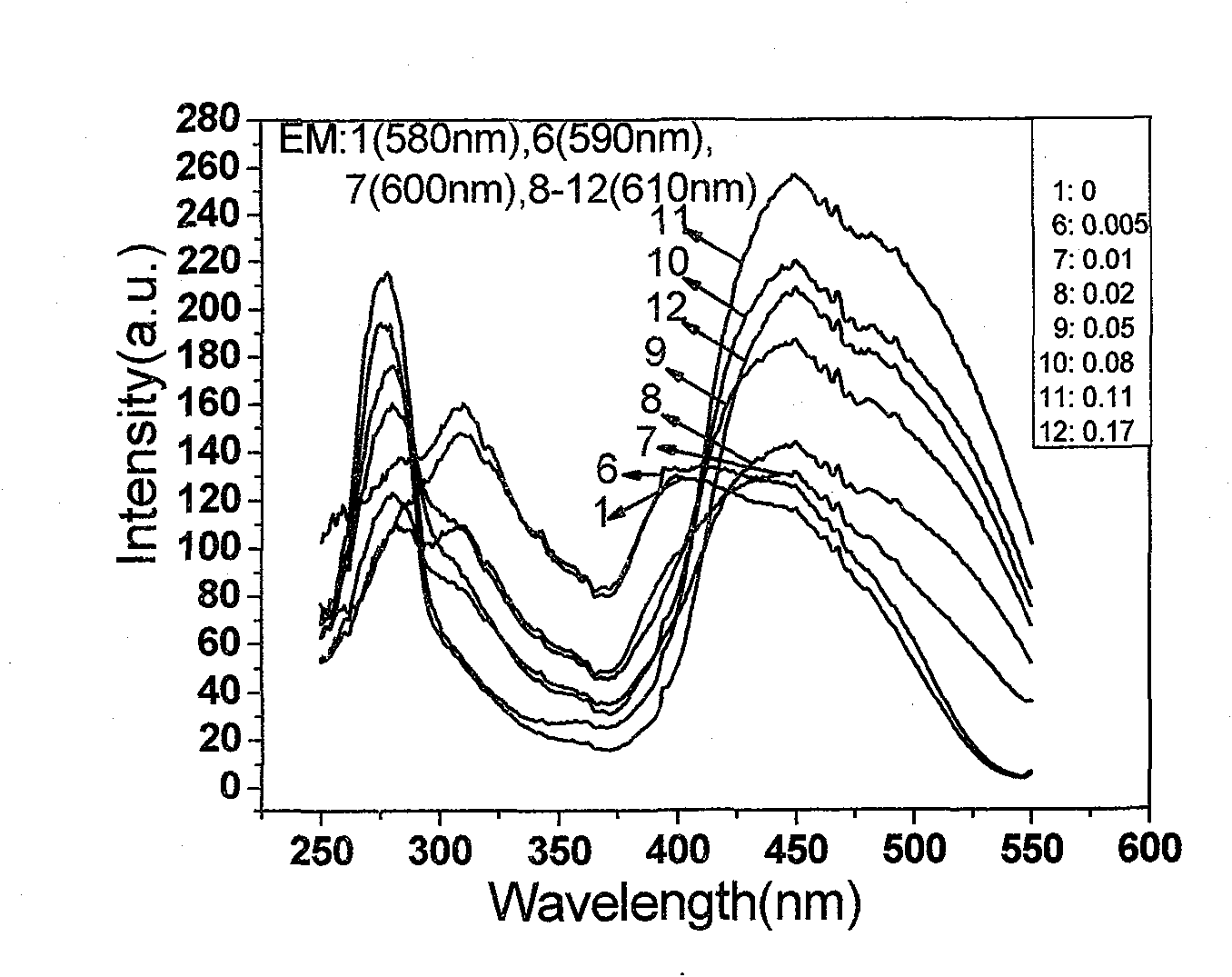

[0040] Weigh Li according to the molar ratio: Li:Sr:Si:Eu=2:0.995:1:0.005 2 CO 3 , SrCO 3 , SiO 2 , Eu 2 o 3 , the above raw materials are all analytically pure, after mixing the above raw materials evenly, put them into an alumina crucible and bake in air, keep the temperature at 600°C for 6 hours, and then bake at 850°C for 4 hours in a reducing atmosphere. The resulting product is crushed, washed with water, removed of impurities, and dried to obtain the chemical composition of Li 2 Sr 0.995 SiO 4 :0.005Eu 2+ sample. Its excitation spectrum is shown in Figures 1, 3, 5, and 7 in line 1, and its emission spectrum is shown in Figures 2, 4, 6, and 8 in line 1.

Embodiment 2

[0042] According to the molar ratio: Li:Sr:Si:Eu:P=2:0.995:0.9925:0.005:0.01 Weigh Li 2 CO 3 , SrCO 3 , SiO 2 , Eu 2 o 3 , (NH 4 ) 2 HPO 4 , the above raw materials are all analytically pure, after mixing the above raw materials evenly, put them into an alumina crucible and bake in air, keep the temperature at 600°C for 6 hours, and then bake at 850°C for 4 hours in a reducing atmosphere. The resulting product is crushed, washed with water, removed of impurities, and dried to obtain the chemical composition of Li 2 Sr 0.995 (SiO 4 ) 0.9925 (PO 4 ) 0.01 :0.005Eu 2+ sample. Its excitation spectrum is shown in line 2 in Figure 1, and its emission spectrum is shown in line 2 in Figure 2.

Embodiment 3

[0044] Weigh Li according to molar ratio: Li:Sr:Si:Eu:P=2:0.995:0.9775:0.005:0.03 2 CO 3 , SrCO 3 , SiO 2 , Eu 2 o 3 , (NH 4 ) 2 HPO 4 , the above raw materials are all analytically pure, after mixing the above raw materials evenly, put them into an alumina crucible and bake in air, keep the temperature at 600°C for 6 hours, and then bake at 850°C for 4 hours in a reducing atmosphere. The resulting product is crushed, washed with water, removed of impurities, and dried to obtain the chemical composition of Li 2 Sr 0.995 (SiO 4 ) 0.9775 (PO 4 ) 0.03 :0.005Eu 2+ sample. Its excitation spectrum is shown in line 3 in Figure 1, and its emission spectrum is shown in line 3 in Figure 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com