Method for preparing jadeite microcrystal glass ceramic composite board

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of glass-ceramic building materials and building materials, can solve the problems of limited application scope, poor surface strength and wear resistance, no jade texture, etc., and achieves stable and reliable effects. The effect of high surface strength and wear resistance, unique jade texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

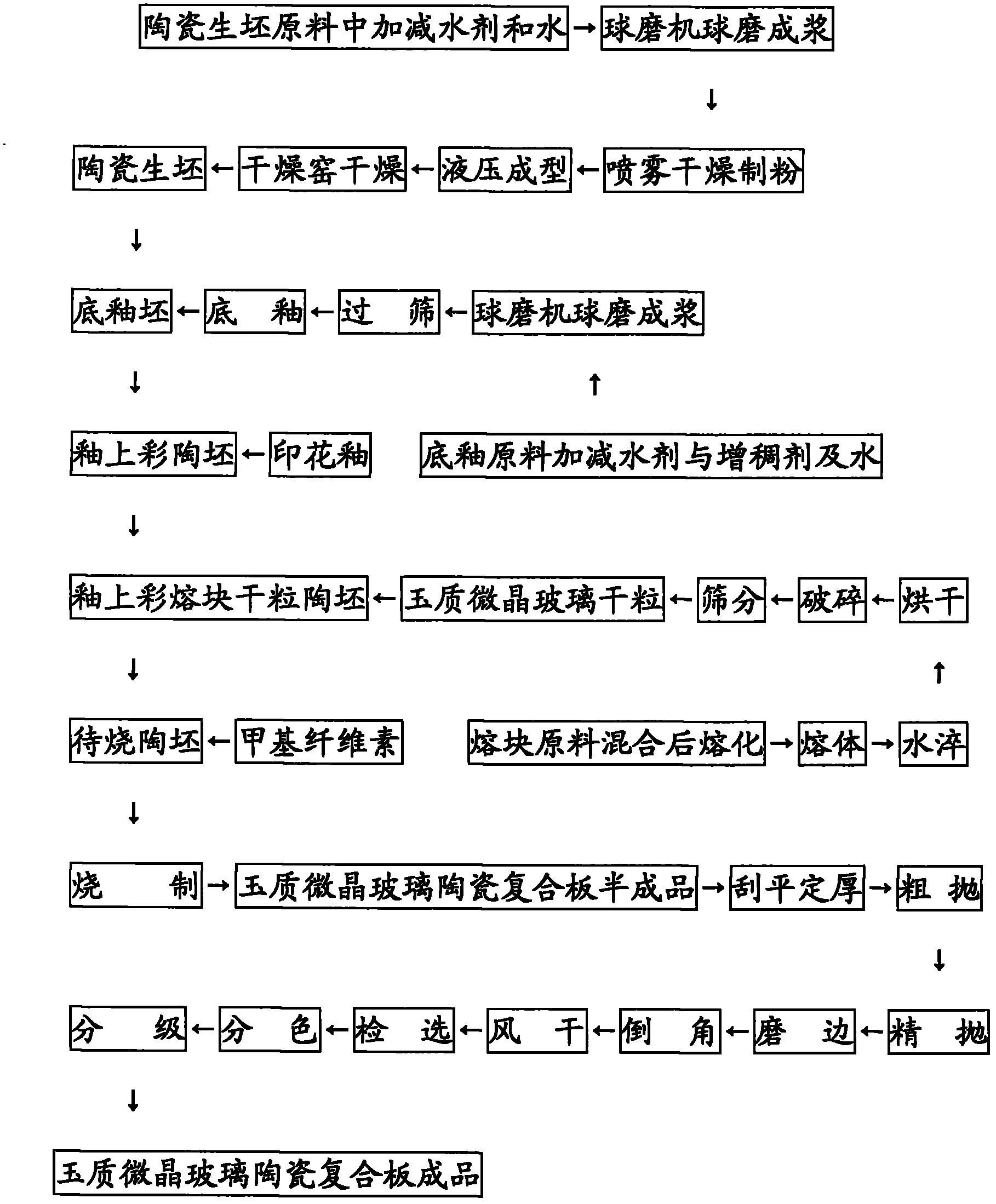

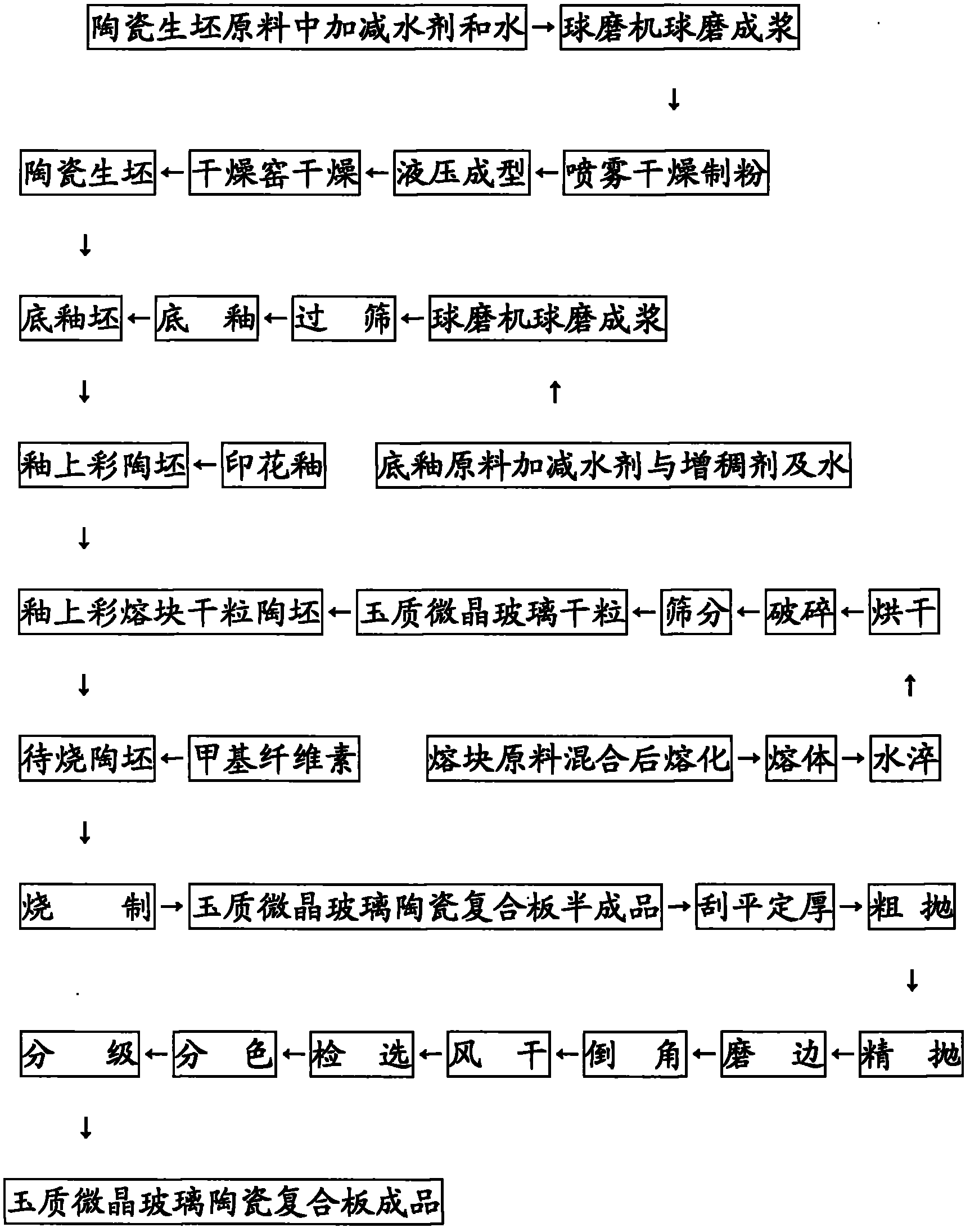

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0041] A preparation method of a jade glass-ceramic composite board:

[0042] ①. Preparation of jade glass-ceramic frit dry granules: quartz, potassium feldspar, albite, calcite, dolomite, barium carbonate, sodium carbonate, potassium carbonate, borax, boric acid, calcium phosphate each with a thickness of less than 100 mesh 80-700 kg is mixed evenly as raw materials and sent to the glass tank kiln for melting. The melting temperature is 1520-1600°C. 2 50-70%, Al 2 o 3 5-20%, CaO 0-10%, MgO 0-8%, K 2 O+Na 2 O 2-10%, BaO 0-8%, B 2 o 3 0-8%, P 2 o 5 0-5% and 30-200 mesh jade glass-ceramic frit dry granules with moisture <0.5% for use;

[0043] ②. Preparation of ceramic green body: 385-12250 kg each of kaolin, clay, quartz, potassium feldspar, albite, and talc with a particle size of less than 1 mm are mixed as cerami...

specific Embodiment approach 2

[0064] Carry out by specific embodiment one, just as shown in the accompanying drawing of description, just:

[0065] 1. In the preparation of the jade quality glass-ceramic frit dry granules of ①: press SiO 2 56.53%, Al 2 o 3 9.92%, CaO 5.53%, MgO 6.12%, K 2 O+Na 2 O 6.25%, BaO 5.86%, B 2 o 3 6.71%, P 2 o 5 3.08%, select the corresponding proportion of quartz, potassium feldspar, calcite, dolomite, soda ash, barium carbonate, boric acid, potassium nitrate, calcium phosphate, less than 100 mesh, for batching. Mix in a mixer for 30 minutes, melt in a pool kiln of 22 square meters, the melting temperature is 1580°C, and the storage time is about 24 hours. The clarified melt is water quenched, dried, crushed, and sieved , to obtain 30-200 mesh glass pellets. Then, through a dry distributing machine, evenly distribute the prepared jade glass-ceramic frit dry particles on the ceramic green body with printed patterns, and the cloth amount is 3.5-6Kg / m 2 , and then spray...

specific Embodiment approach 3

[0068] Carry out by the step of specific embodiment one, but the difference with specific embodiment one lies in the prescription of jade glass-ceramic frit. The formula composition of its jade glass-ceramic frit is SiO 2 53.21%, Al 2 o 3 9.85%, CaO 5.90%, MgO 5.14%, K 2 O+Na 2 O 8.22%, BaO 7.56%, B 2 o 3 6.99%, P 2 o 5 3.13%. Also received the expected effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com