Cast forming method of small titanium alloy or titanium-aluminum alloy complicated casting

A titanium-aluminum alloy and casting forming technology, which is applied in the casting field of titanium alloy or titanium-aluminum alloy castings, can solve the problems of incapable of casting forming shape, low material utilization rate, complicated centrifugal casting method and process, etc. Low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

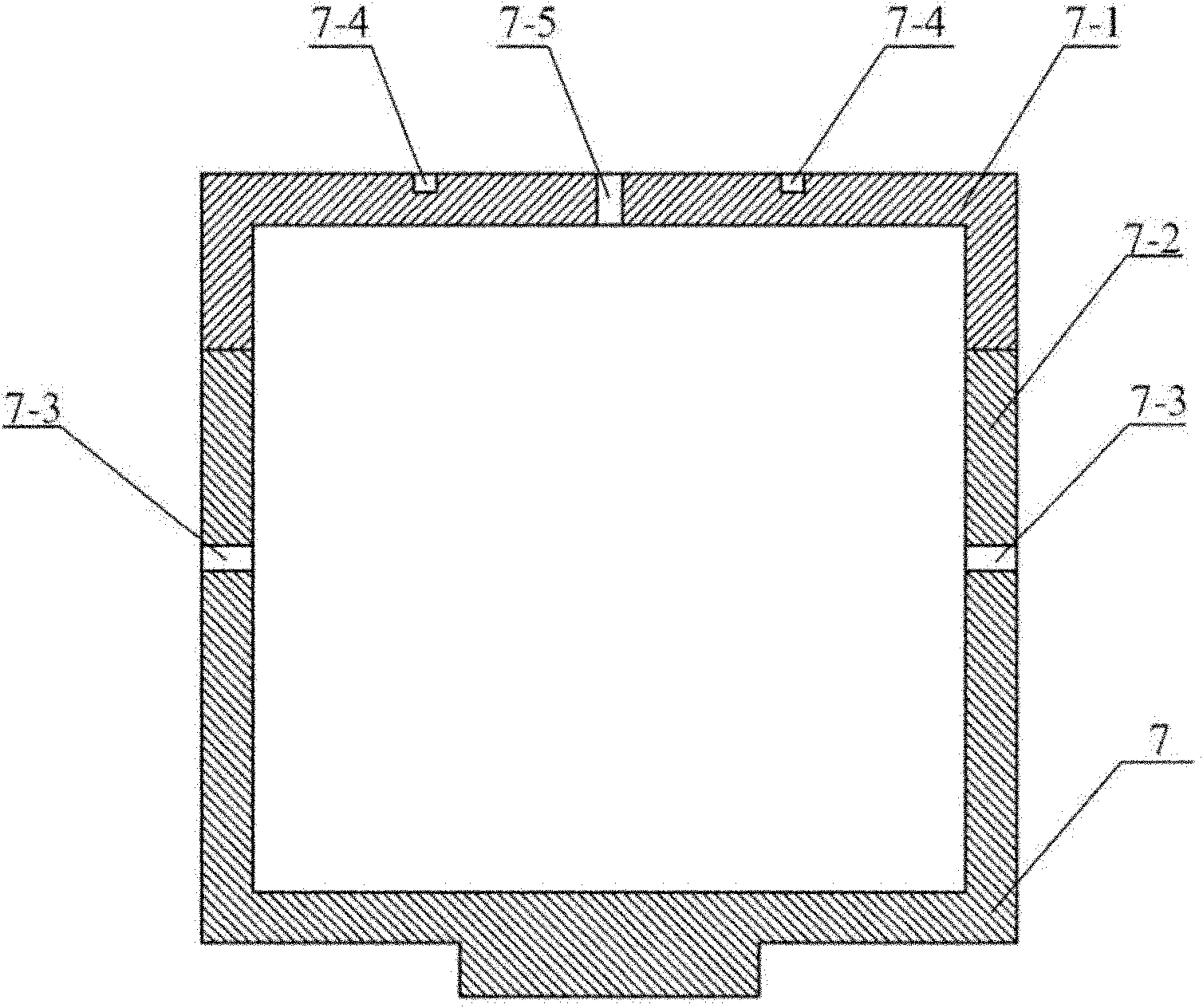

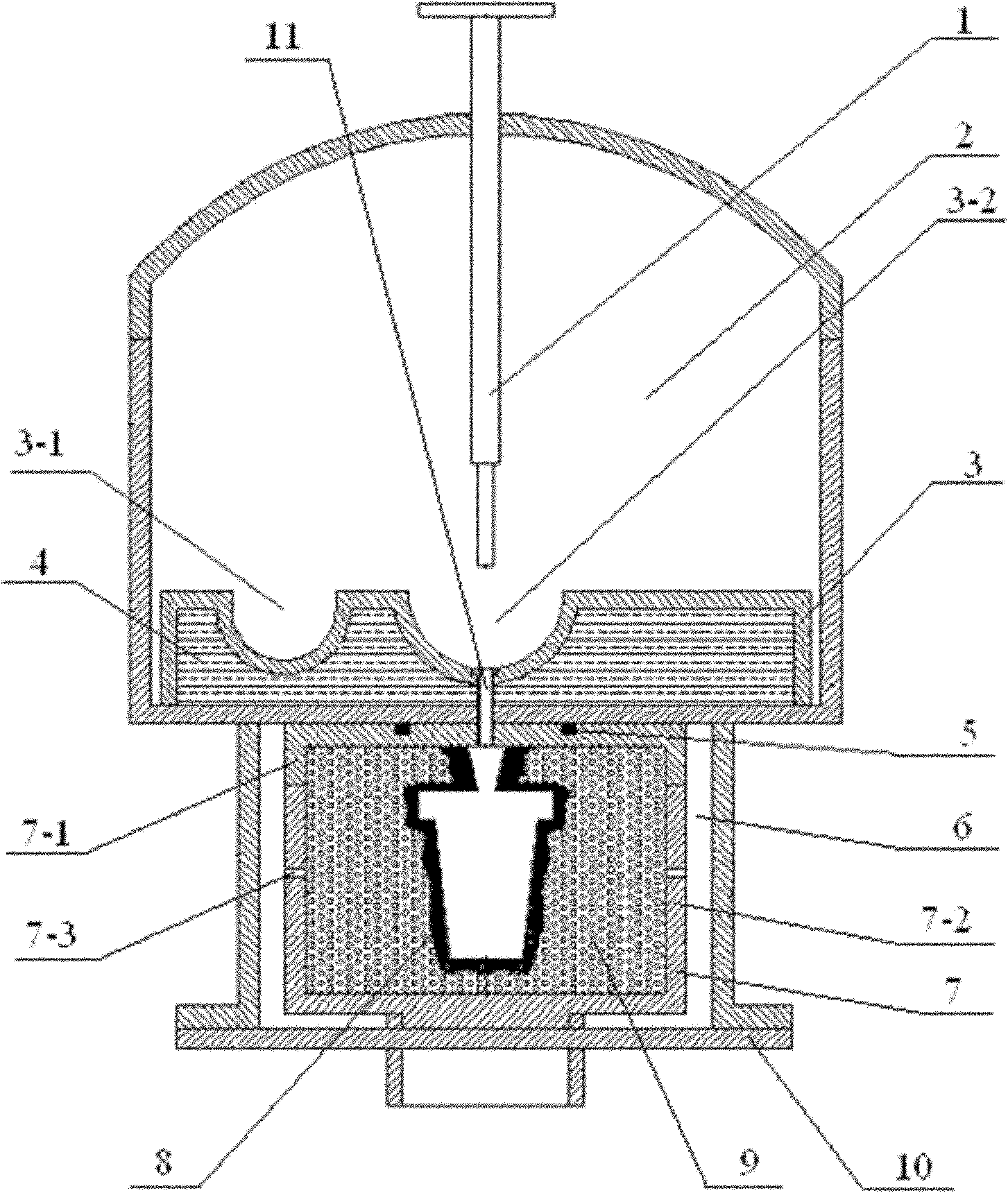

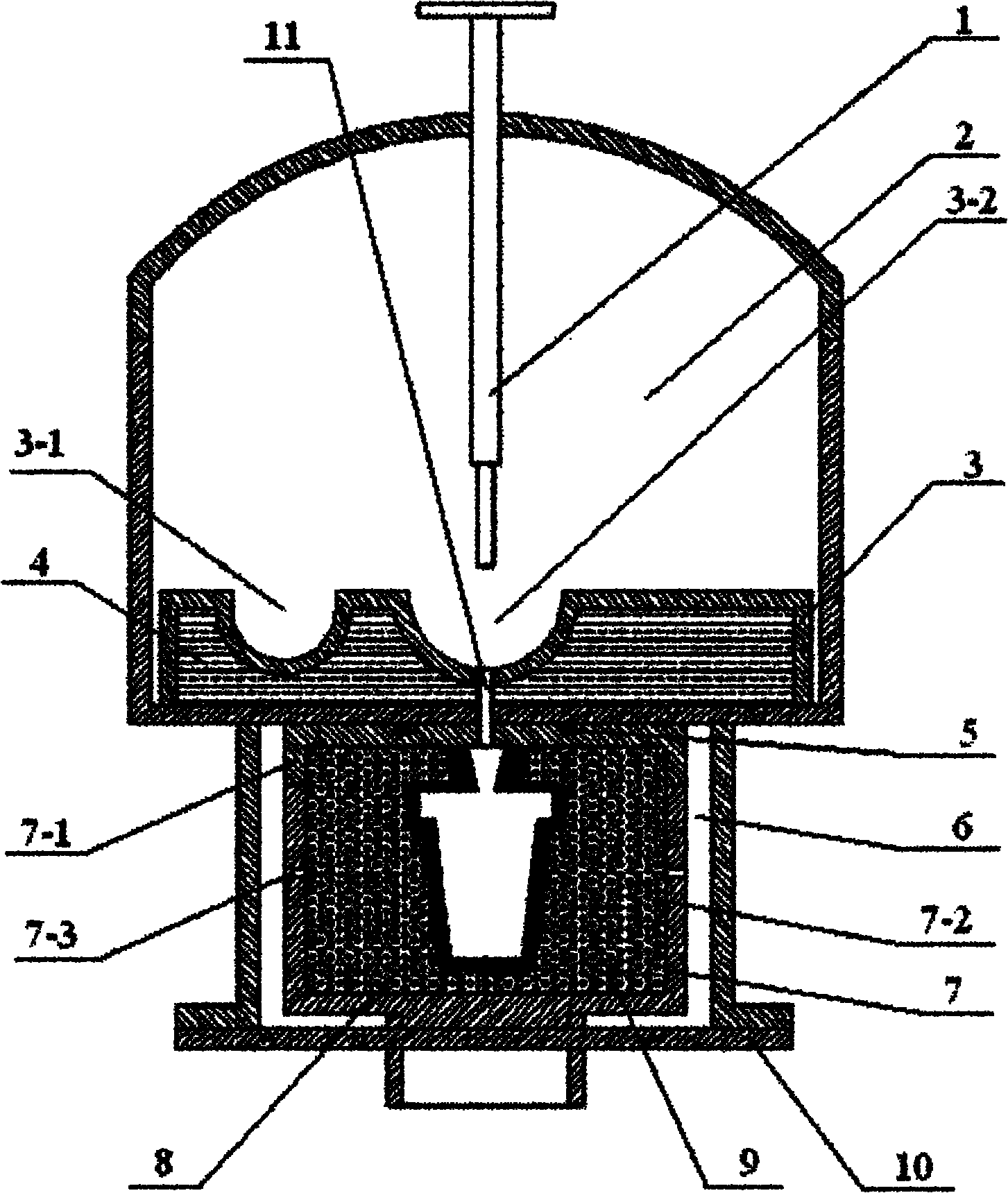

[0008] Specific implementation mode one: (see attached figure 1 and figure 2 ) The casting method of a small-sized titanium alloy or titanium-aluminum alloy complex casting of the present embodiment is carried out according to the following steps: 1. The gas-permeable shell 8 of titanium alloy or titanium-aluminum alloy casting is prepared by the method of investment casting in the prior art ; Two, prepare the bottom leakage type vacuum suction casting container 7, this container 7 is made up of cavity 7-2 and loam cake 7-1, has ventilation hole 7-3 on the side wall of cavity body 7-2, loam cake 7 -1 has a gate 7-5, and the upper surface of the upper cover 7-1 has an annular sealing groove 7-4, and the gate 7-5 is located in the ring of the sealing groove 7-4; 3. Prepare step 1 The molded shell 8 is fixed in the container 7 prepared in step 2 with an air-permeable filler 9, the container loam cake 7-1 is covered, the sealing ring 5 is installed in the sealing groove 7-4 of t...

specific Embodiment approach 2

[0010] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, when using the investment casting method to prepare the shell 8 of titanium alloy or titanium aluminum alloy casting, the particle size of the surface sand is 80 mesh to 100 mesh. mesh, the particle size of the second layer sand is 20 mesh to 40 mesh, and the particle size of the back layer sand is 8 mesh to 20 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is: when using investment casting method to prepare the shell 8 of titanium alloy or titanium aluminum alloy casting in step one, the grain size of surface sand is 90 mesh, two The particle size of the layer sand is 30 mesh, and the particle size of the back layer sand is 16 mesh. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com