Hard aluminum alloy for metal die casting of precision electronic product structural member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

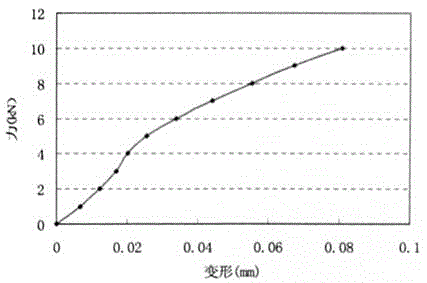

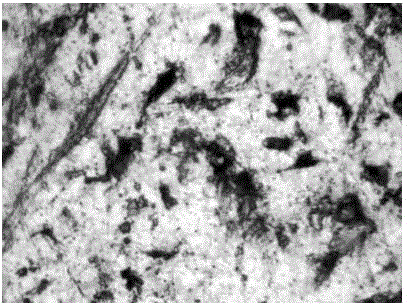

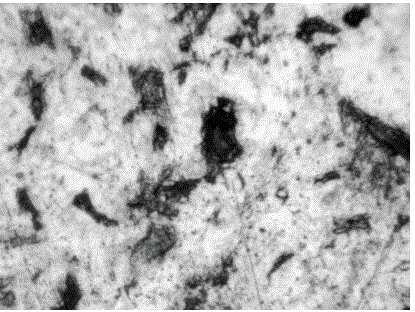

Image

Examples

Embodiment 1

[0042] Step 1: The ingredients are shown in Table 1-1.

[0043]

[0044] Step 2: Melting

[0045] The alloy is smelted in a graphite crucible resistance furnace. Aluminum-silicon alloy, aluminum-manganese alloy, aluminum-nickel alloy, aluminum-chromium alloy and pure aluminum ingot are loaded at room temperature at the same time; aluminum-copper alloy and pure zinc ingot are added at 720°C; aluminum-titanium-boron rare-earth alloy is added at 740°C and stirred for 5 minutes. Use C 2 Cl 6 For refining with refining agent, the amount of flux added during refining is about 2% of the weight of the raw material. Stir up and down with a refining spoon until the liquid surface becomes a mirror surface. After standing for 10 minutes, remove the slag, add a small amount of covering agent, add pure magnesium ingot, and stand still. Leave it for 5 minutes, stir evenly, and then die-cast at 720°C.

[0046] Step 3: Die casting manufacturing

[0047] 1600N horizontal cold-chamber die-casting mac...

Embodiment 2

[0053] Step 1: The ingredients are shown in Table 2-1.

[0054]

[0055] Step 2: Melting

[0056] The alloy is smelted in a graphite crucible resistance furnace. Aluminum-silicon alloy, aluminum-manganese alloy, aluminum-nickel alloy, aluminum-chromium alloy, aluminum-vanadium alloy and pure aluminum ingot are simultaneously loaded into the furnace at room temperature; aluminum-copper alloy and pure zinc ingot are added at 720°C; after aluminum-titanium-boron rare-earth alloy is added at 740°C Stir for 5min. Use C 2 Cl 6 For refining with refining agent, the amount of flux added during refining is about 2% of the weight of the raw material. Stir up and down with a refining spoon until the liquid surface becomes a mirror surface. After standing for 10 minutes, remove the slag, add a small amount of covering agent, add pure magnesium ingot, and stand still. Leave it for 5 minutes, stir evenly, and then die-cast at 720°C.

[0057] Step three:

[0058] 1600N horizontal cold-chambe...

Embodiment 3

[0064] Step 1: The ingredients are shown in Table 3-1.

[0065]

[0066] Step 2: Melting

[0067] The alloy is smelted in a graphite crucible resistance furnace. Aluminum-silicon alloy, aluminum-manganese alloy, aluminum-nickel alloy, aluminum-chromium alloy, aluminum-vanadium alloy and pure aluminum ingot are simultaneously loaded into the furnace at room temperature; aluminum-copper alloy and pure zinc ingot are added at 720°C; after aluminum-titanium-boron rare-earth alloy is added at 740°C Stir for 5min. Use C 2 Cl 6 For refining with refining agent, the amount of flux added during refining is about 2% of the weight of the raw material. Stir up and down with a refining spoon until the liquid surface becomes a mirror surface. After standing for 10 minutes, remove the slag, add a small amount of covering agent, add pure magnesium ingot, and stand still. Leave it for 5 minutes, stir evenly, and then die-cast at 720°C.

[0068] Step three:

[0069] 1600N horizontal cold-chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com