Integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on vacuum condition

A vacuum condition, acousto-magnetic coupling technology, applied in the field of metal material preparation, can solve problems such as inapplicability, and achieve the effect of inhibiting metal heterogeneous nucleation, eliminating clusters, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

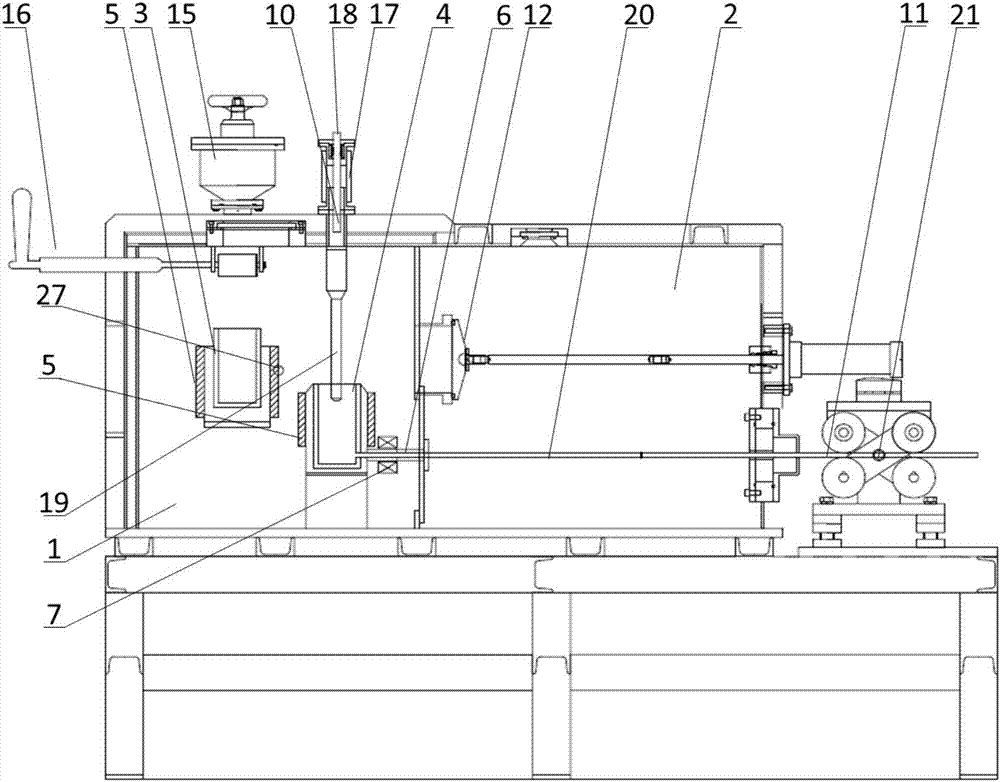

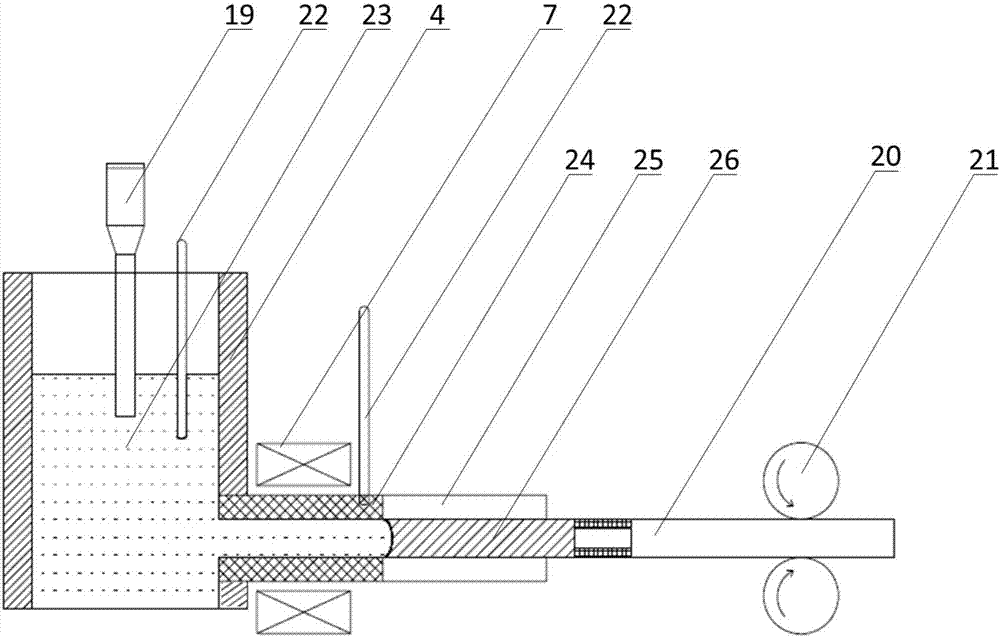

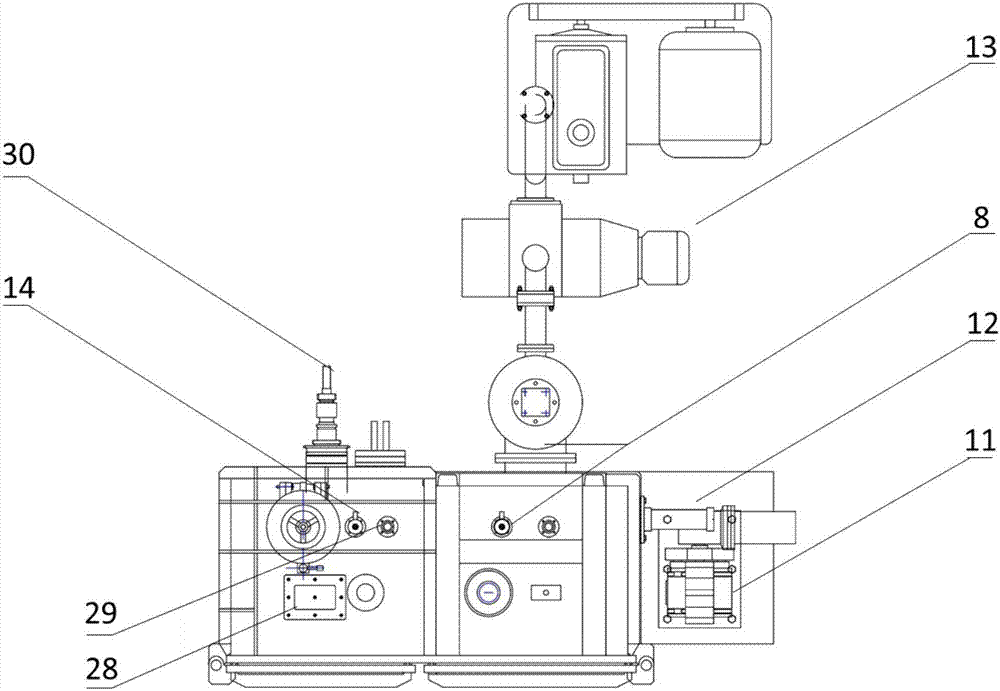

[0038] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0039] figure 1 A device for horizontal continuous casting of electromagnetic / ultrasonic coupled fields under vacuum is shown. Before smelting the alloy, move the draw bar 20 and the continuous casting slab 26 to the initial position so that the end of the continuous casting slab 26 is located in the graphite mold 24, and then put the alloy raw material into the melting furnace 3 and prepare for smelting; during smelting, first Open the isolation valve 12, and close the exhaust vent 14 and the inert gas valve 29, then by controlling the vacuum control system 8, turn on the vacuum pump 13, and then vacuumize the first vacuum chamber 1 and the second vacuum chamber 2 to 0.01Pa, and then close the vacuum pump 13 Open the inert gas valve 29 afterwards, fill argon gas to 0.05MPa in the first vacuum chamber 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com