Conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and preparation method thereof

A cable sheathing material and oil-resistant technology, which is applied to conductive materials, insulated cables, cables and other directions dispersed in non-conductive inorganic materials, can solve the problems of no results and related reports on cable sheathing materials, and achieve improvement. Processing performance, low plasticizing temperature, and the effect of preventing droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

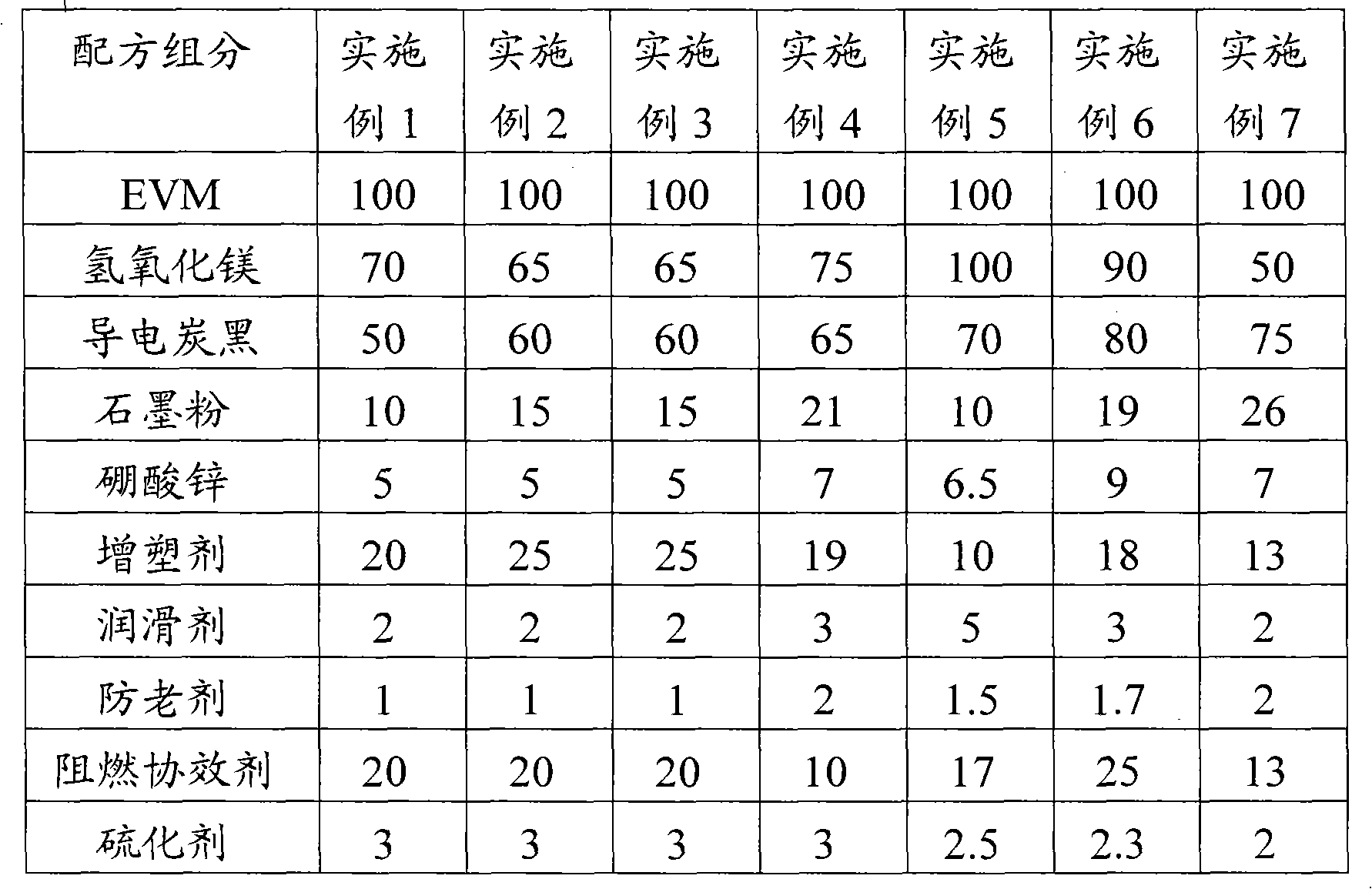

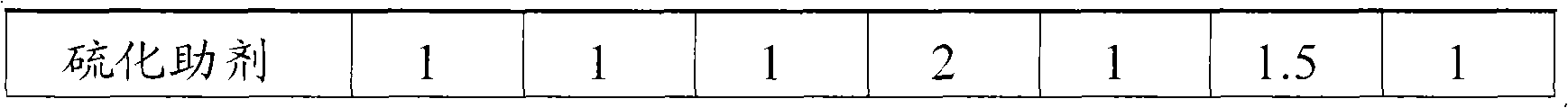

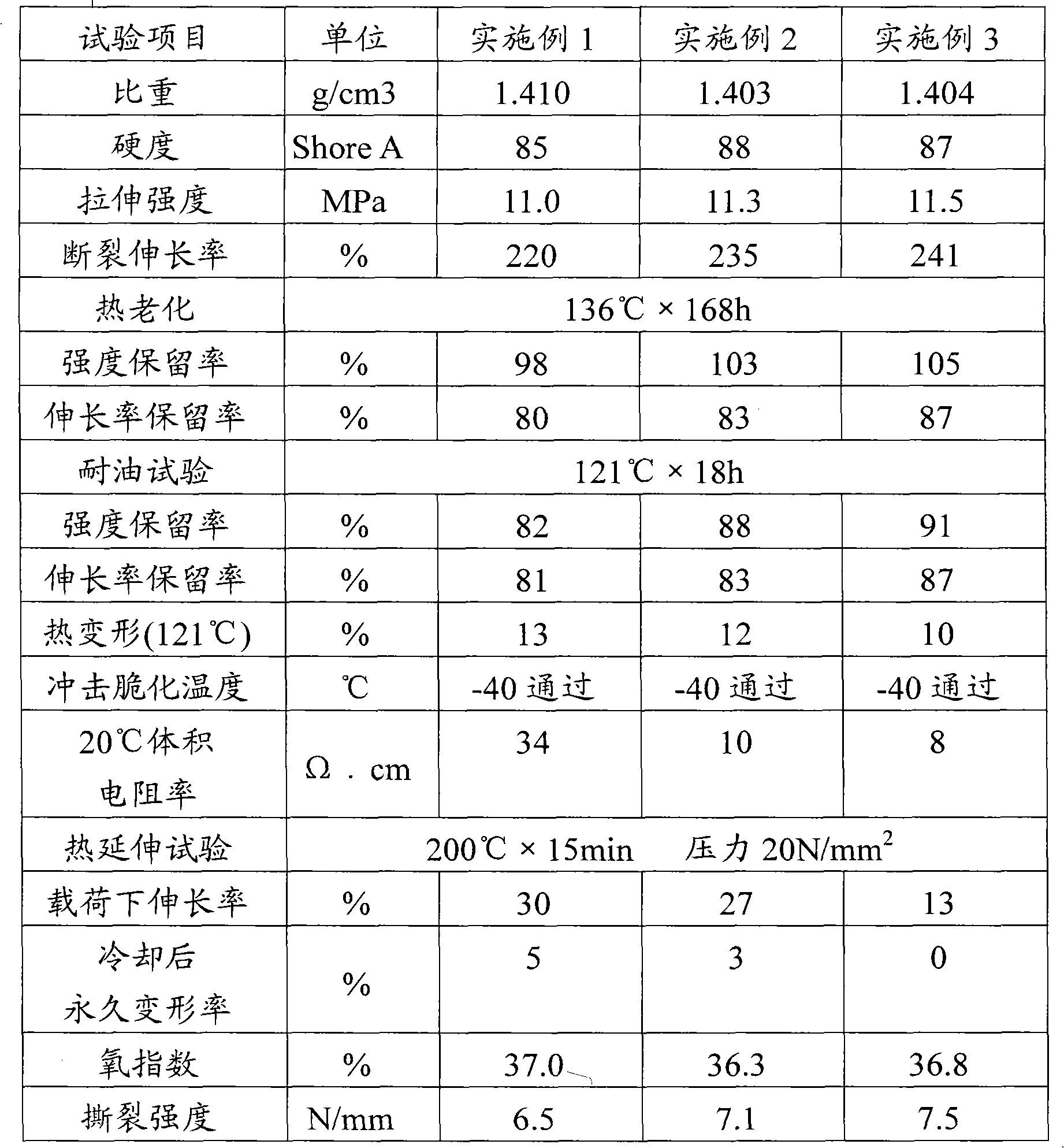

[0037] Examples 1-7: A conductive low-smoke, halogen-free, flame-retardant and oil-resistant cable sheathing material

[0038] One, raw material formula: the specific proportioning of embodiment 1~7 is shown in table 1.

[0039] 2. Preparation method, prepare materials according to the ratio in Table 1, accurately weigh, put the raw materials except vulcanizing agent and auxiliary vulcanizing agent into the internal mixer for mixing, and the principle of feeding is to let the materials mix evenly, so it can be Feeding in batches, such as: raw rubber, half of the carbon black, half of the flame retardant, and then small additives, and then cover the remaining carbon black and flame retardant. Let the main engine rotate for 30 seconds without pressing the top bolt, so that the materials can be stirred and mixed automatically. After kneading, add vulcanizing agent and co-vulcanizing agent and mix again, turn it over and over again until no liquid vulcanizing agent can be seen. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com