Centrifugally-cast burr cylinder sleeve and preparation method thereof

A centrifugal casting and cylinder liner technology, which is applied to casting molding equipment, cylinders, casting molds, etc., can solve the problems of reduced service life of the mold, deterioration of the metallographic structure of the cylinder liner, and poor filling ability of molten iron, so as to reduce heat, Good metallographic structure and good burr formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A centrifugal casting burr cylinder liner, in weight percentage, the chemical composition of the burr cylinder liner provided by this example is as follows:

[0028]

[0029] The preparation method of the burr cylinder liner of above-mentioned centrifugal casting comprises the following steps:

[0030] (1) Accurately weigh each raw material, use an intermediate frequency induction furnace for melting, add silicon carbide powder (particle size 0.2~10mm) accounting for 0.1% of the molten iron mass, and control the temperature of the molten iron at 1550°C;

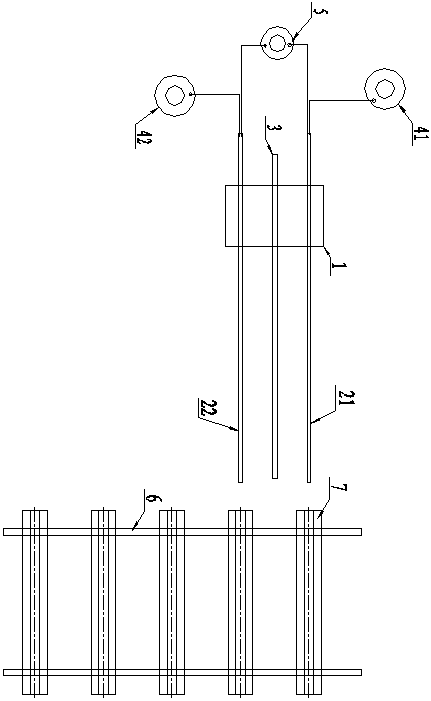

[0031] (2) Preparation of paint: Mix bentonite and water at a mass ratio of 1:10, stir for 10 hours, weigh 100kg of the solution, add 16kg of diatomite (-300 mesh accounts for more than 70%), and stir for 1.5 hours ,Such as figure 1 As shown, add the stirred paint into the first paint pressure tank 41, adjust the pressure of the first paint pressure tank 41 to 0.15MPa, add the second paint prepared in advance in th...

Embodiment 2

[0037] A centrifugal casting burr cylinder liner, in weight percentage, the chemical composition of the burr cylinder liner provided by this example is as follows:

[0038]

[0039] The preparation method of the burr cylinder liner of above-mentioned centrifugal casting comprises the following steps:

[0040] (1) Accurately weigh each raw material, use an intermediate frequency induction furnace for melting, add silicon carbide powder (particle size 0.2~10mm) accounting for 0.15% of the molten iron mass, and control the temperature of the molten iron at 1500°C;

[0041] (2) Preparation of paint: Mix bentonite and water at a mass ratio of 1:10, stir for 11 hours, weigh 100kg of the solution, add 15kg of diatomite (-300 mesh accounts for more than 70%), and stir for 1 hour ,Such as figure 1 As shown, add the stirred paint into the first paint pressure tank 41, adjust the pressure of the first paint pressure tank 41 to 0.1MPa, add the second paint prepared in advance in the sec...

Embodiment 3

[0047] A centrifugal casting burr cylinder liner, in weight percentage, the chemical composition of the burr cylinder liner provided by this example is as follows:

[0048]

[0049] The preparation method of the burr cylinder liner of above-mentioned centrifugal casting comprises the following steps:

[0050] (1) Accurately weigh each raw material, use an intermediate frequency induction furnace to smelt, add silicon carbide powder (particle size 0.2~10mm) accounting for 0.2% of the molten iron mass, and control the temperature of the molten iron to 1550°C;

[0051] (2) Preparation of paint: Mix bentonite and water at a mass ratio of 1:10, stir for 12 hours, weigh 100kg of the solution, add 20kg of diatomite (-300 mesh accounts for more than 70%), and stir for another 2 hours ,Such as figure 1 As shown, add the stirred paint into the first paint pressure tank 41, adjust the pressure of the first paint pressure tank 41 to 0.2MPa, add the second paint prepared in advance in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com