Investment casting utilizing flexible wax pattern tool

A technology of investment casting and flexible mold, which is applied in the field of investment casting and can solve problems such as size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As part of an investment casting process—such as may be used to cast gas turbine blades or other components with complex internal cooling passages—a ceramic core is first fabricated that will define the internal cooling passages. shape. Figure 1 illustrates such a ceramic core 10, which may be formed by any known method.

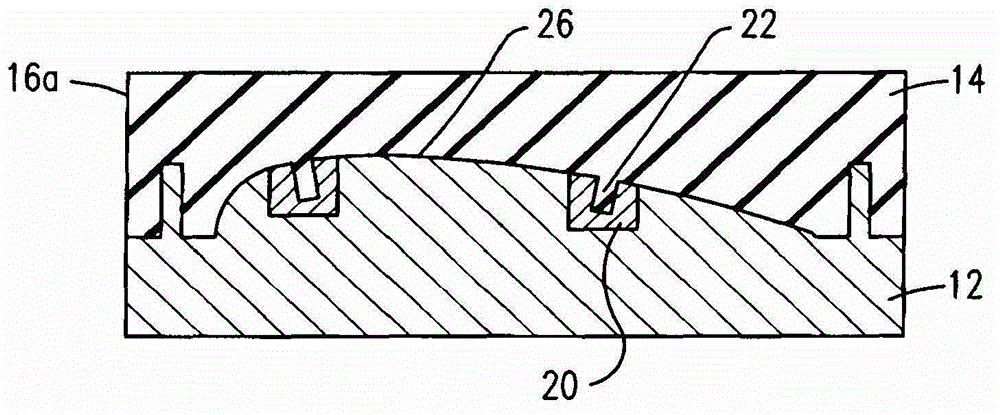

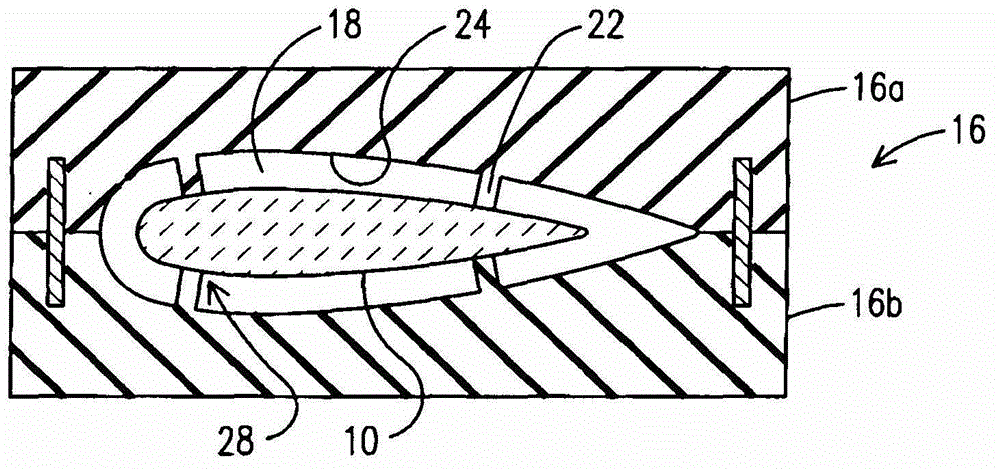

[0034] After the ceramic core has been produced, the next step in the investment casting process is to use the core as part of a wax pattern tool used to cast wax around the core to define the final outer surface shape of the cast blade or other cast part . Wax pattern tool designs in the prior art are complex and expensive when multiple opening surfaces are required to remove the tool from the wax pattern or other cast part due to part geometry. The present invention provides a new method for wax-up tooling that reduces the time and cost of tooling to a fraction of the time and cost required for traditional wax-up tooling, and provides the ability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com