Sludge carbonization device for environmental protection equipment

A technology of carbonization device and environmental protection equipment, applied in sludge treatment, pyrolysis treatment of sludge, water/sludge/sewage treatment, etc. Precise quantitative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

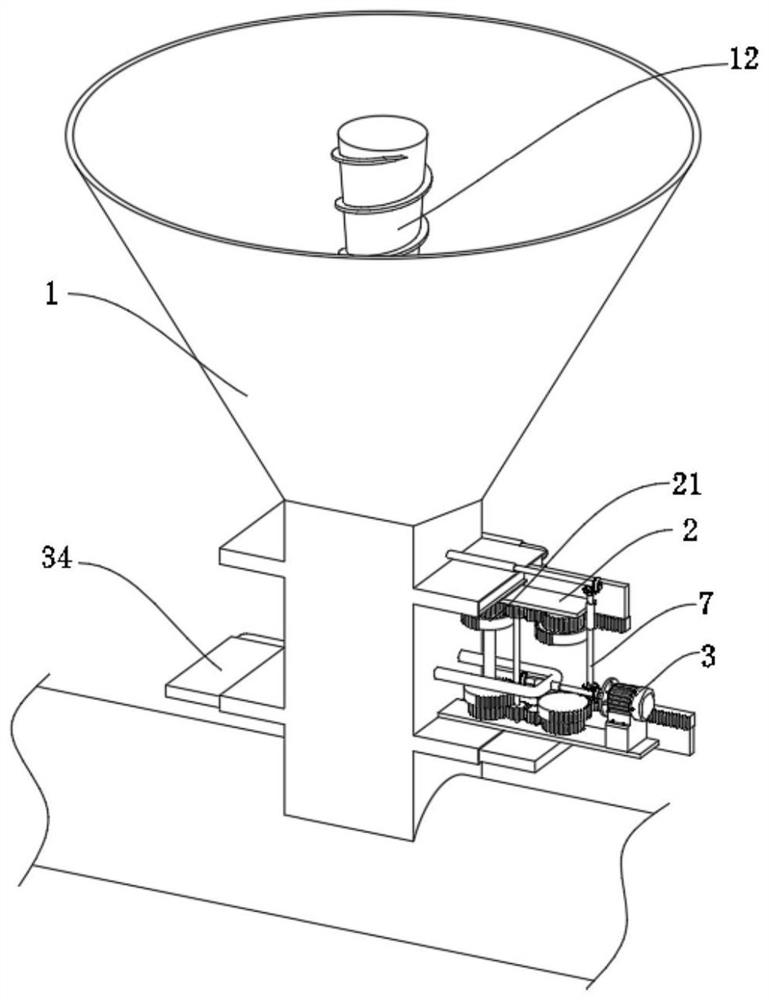

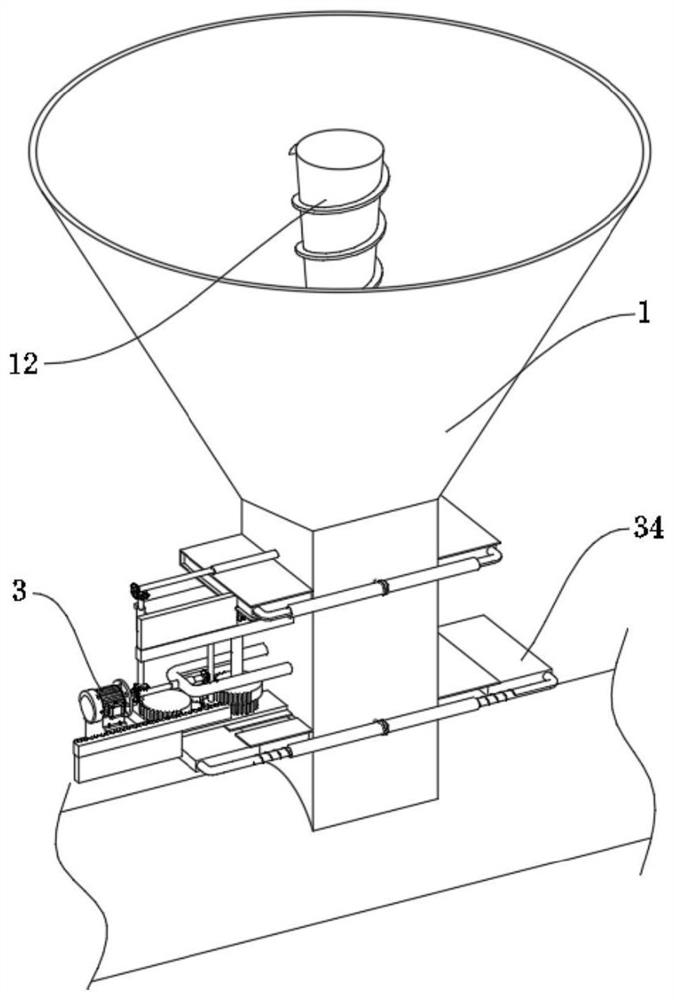

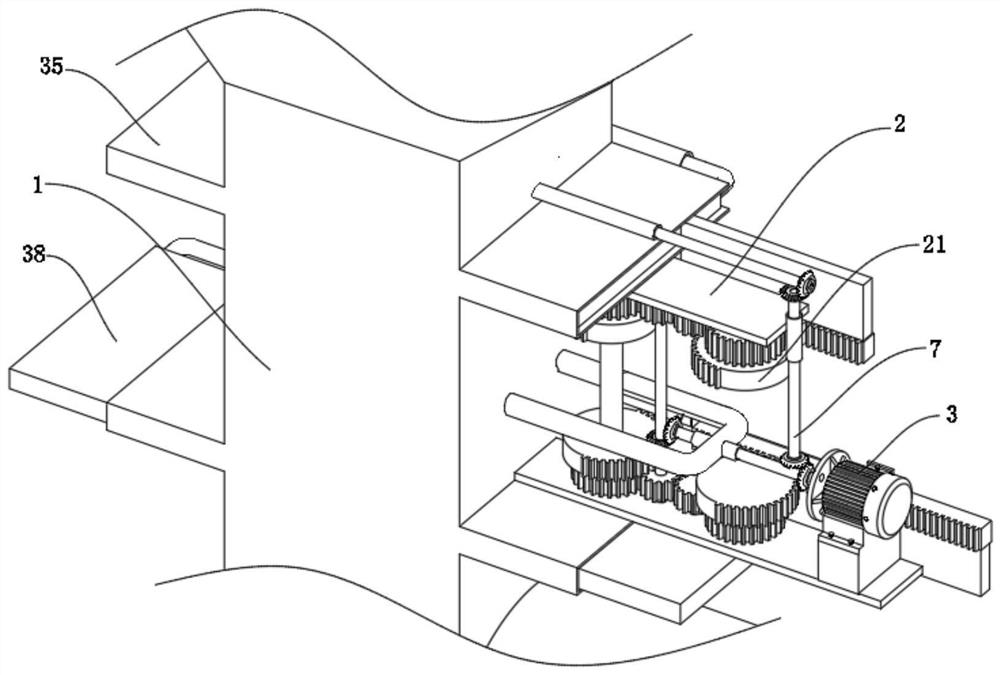

[0032] see Figure 1-6 , 9-10, a sludge carbonization device for environmental protection equipment in the illustration, including: a feeding cylinder 1 communicated and fixed with a connecting pipeline; it is characterized in that: it also includes two fixed plates 2 distributed in a symmetrical structure , the fixed plate 2 is connected and fixed with the feeding cylinder 1, and the outer side of the fixed plate 2 is provided with a blocking assembly 34;

[0033] A motor 3, the output shaft of the motor 3 is fixedly connected with a third rotating rod 4, one end of the third rotating rod 4 is fixedly connected with the sixth bevel gear 5, and the other end of the third rotating rod 4 is fixedly connected with the seventh cone Gear 6, one side of the seventh bevel gear 6 is provided with an adjustment assembly 21 for adjusting the opening and closing of the blocking assembly 34;

[0034] The linkage assembly 7 is used to connect the blocking assembly 34 and the adjustment as...

Embodiment 2

[0042] Reference attached Figure 8 Embodiment 2 is illustrated. This embodiment is further described with respect to Embodiment 1. A protective layer is stuck on the inside of the two movable panels 38 located in the horizontal position. When the movable panels 38 are close to each other, rigidity will appear in the two movable panels 38. Collision, through the protective layer, avoids deformation of structures such as the limit frame 35 and increases the durability of the equipment.

[0043] In order to avoid leakage when the movable plates 38 are closed and opened, the drum 8 is located between two movable plates 38 distributed up and down, and the diameter of the movable plates 38 is adapted to the width of the movable plates 38 .

Embodiment 3

[0045] Reference attached Figure 7 Embodiment 3 is described. This embodiment is further described relative to Embodiment 1. The stirring rod 12 has a structure with a wide top and a narrow bottom, and the roll plate 13 has a downward-sloping structure as a whole.

[0046] Through the rotation of the stirring rod 12 with a wide top and narrow bottom structure and the rolling plate 13 with a downward sloping structure, an inclined downward rotational pressure is given to the sludge in the feeding barrel 1, which facilitates the dewatered sludge to move downward. Entering the drum 8, on the one hand, it crushes and squeezes the sludge with different softness and hardness, and on the other hand, it continuously pushes the sludge into the drum 8 to ensure that the drum 8 is filled with sludge, so that the sludge is quantified accurately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com