Patents

Literature

36results about How to "Help broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

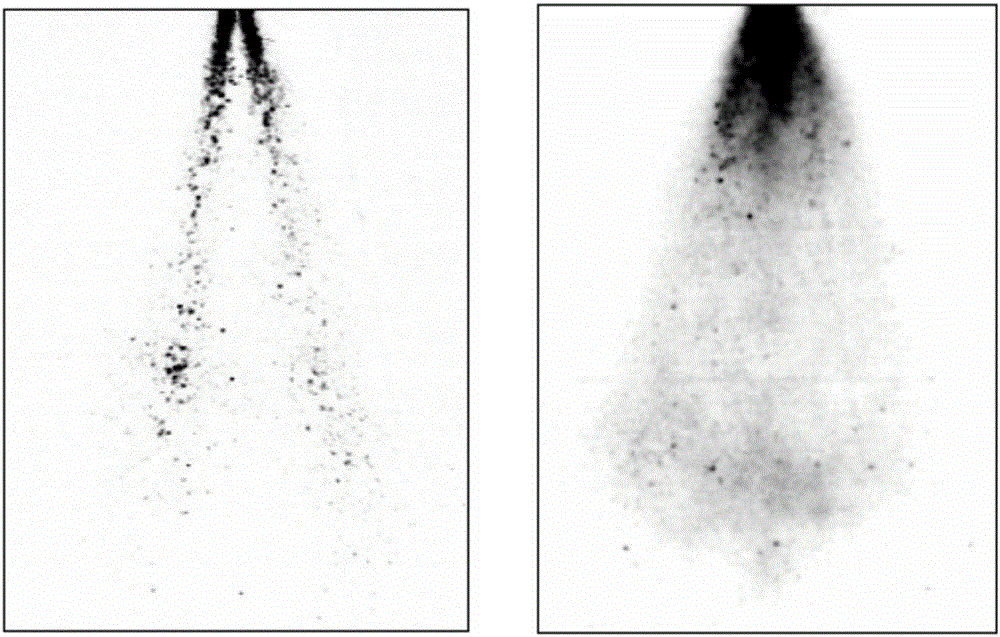

Method for promoting anaerobic digestion of excess sludge through pretreatment of ultrasonic waves and hydrogen peroxide

InactiveCN102424506AGood cracking effectHelp brokenWaste based fuelBiological sludge treatmentChemistryAerobic digestion

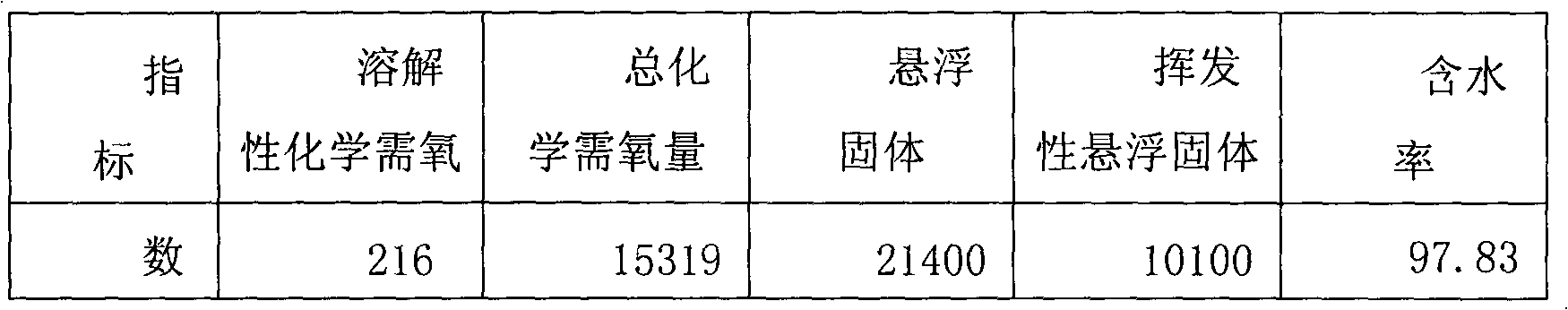

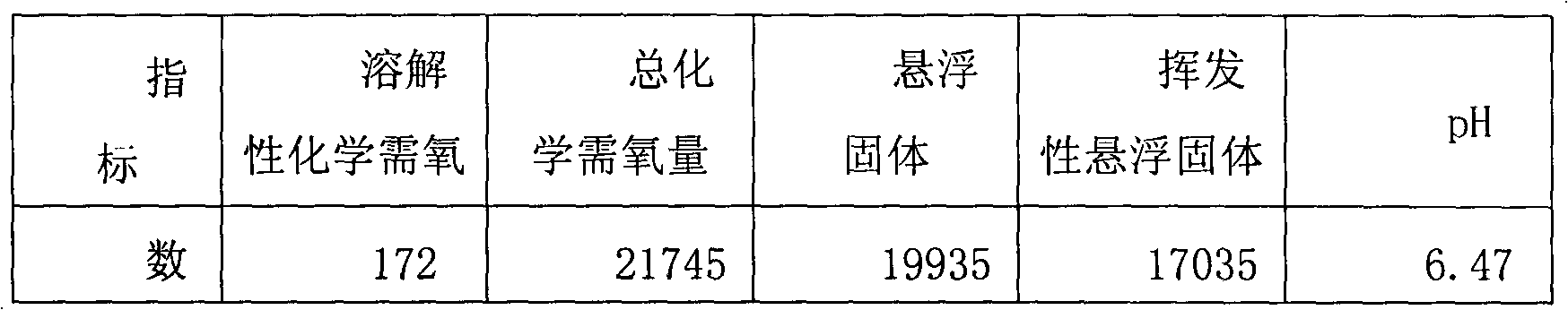

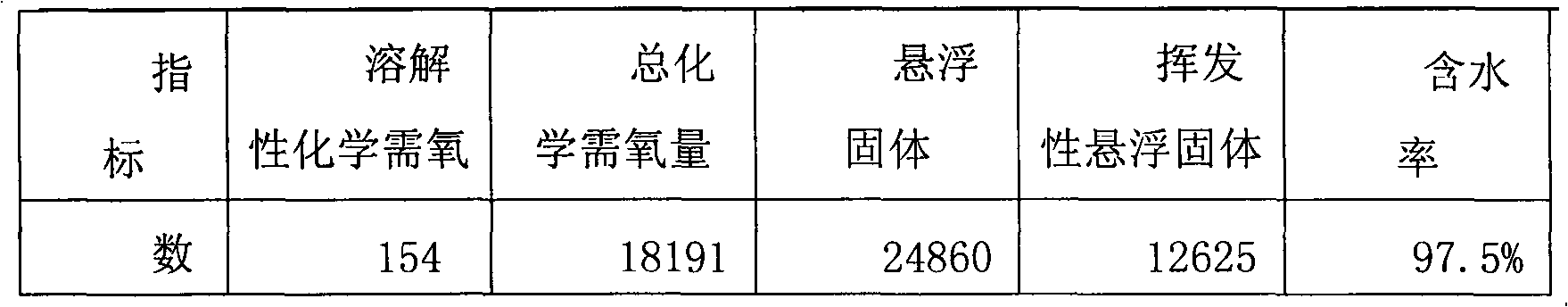

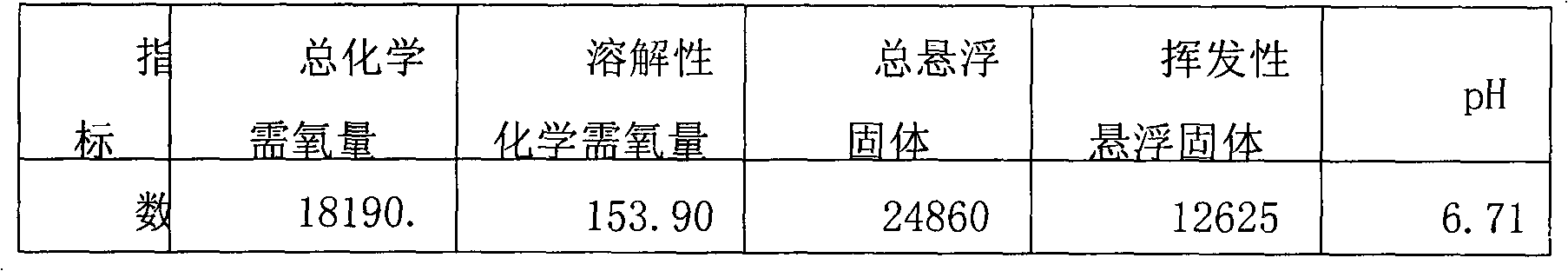

Belonging to the technical field of solid waste treatment, the invention relates to a method for promoting anaerobic digestion of excess sludge through pretreatment of ultrasonic waves and hydrogen peroxide. The method comprises: subjecting the excess sludge of an urban sewage treatment plant to gravity thickening, then adding a certain amount of hydrogen peroxide, conducting rapid stirring and sending the sludge into an ultrasonic reactor for ultrasonic treatment, in which the combined action of ultrasonic waves and hydrogen peroxide destroys the bacterial cell wall structure of the sludge, thus leading to leakage of the cell contents and content increase of dissolved organic matters in water, then sending the treated sludge into an anaerobic digestion reactor for subsequent mesophilic anaerobic digestion; delivering the biogas generated from anaerobic digestion to a gas collection gas for comprehensive utilization. After treatment, the concentration of SCOD (soluble chemical oxygen demand) in the liquid phase sludge can be increased by 23.83 times to 41.18 times, the biogas output can be increased by 17.40%-55.37%, and the methane content of the biogas can be increased by 10%-20%, thus reducing the energy consumption of ultrasonic treatment. For sewage treatment plants of different scales, only by making corresponding modification on existing facilities can good effects be achieved.

Owner:NANKAI UNIV

Method for utilizing enhanced pretreatment to promote anaerobic digestion of excess sludge

InactiveCN102424507AGood cracking effectHelp brokenWaste based fuelBiological sludge treatmentSolubilityChemical oxygen demand

Owner:NANKAI UNIV

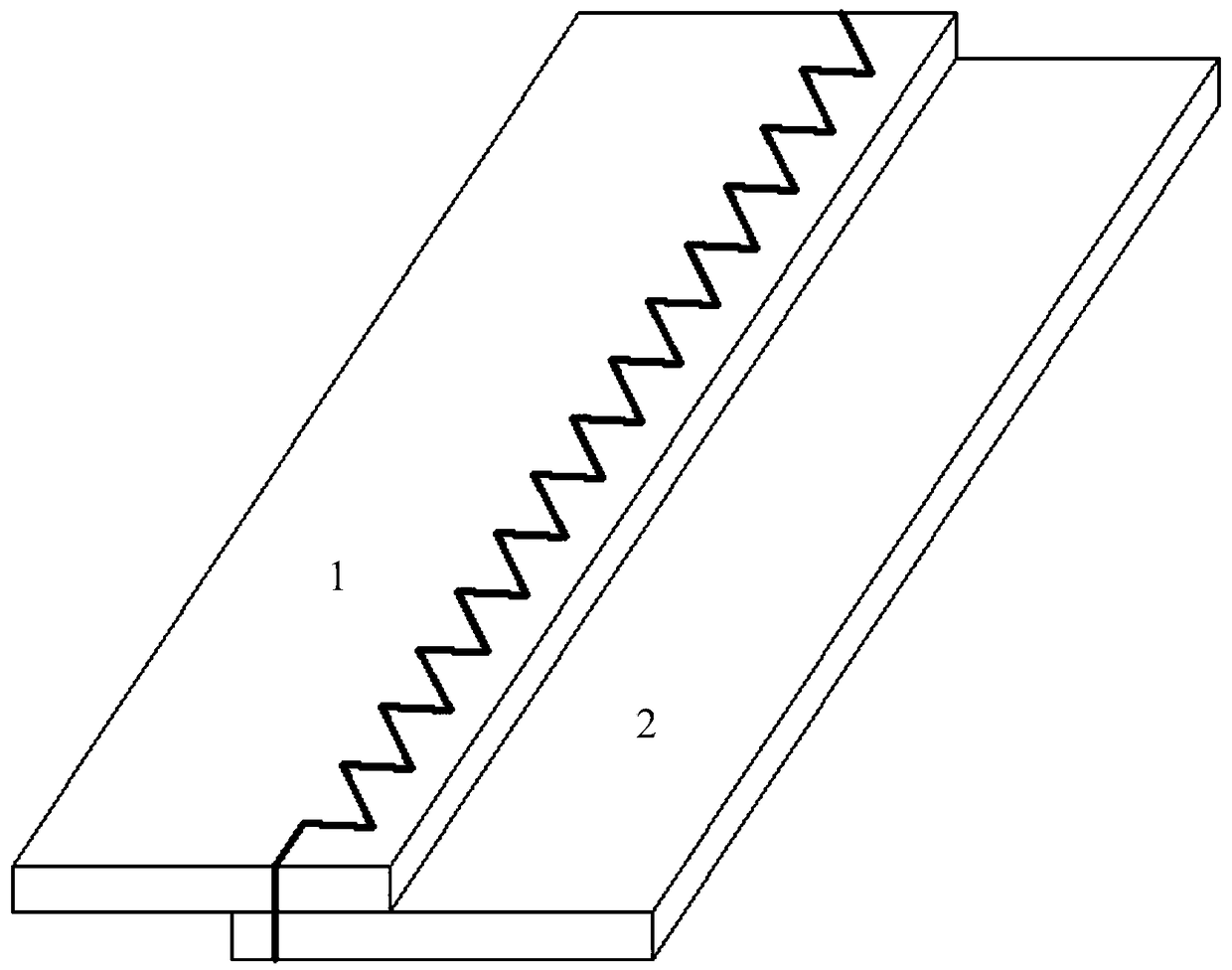

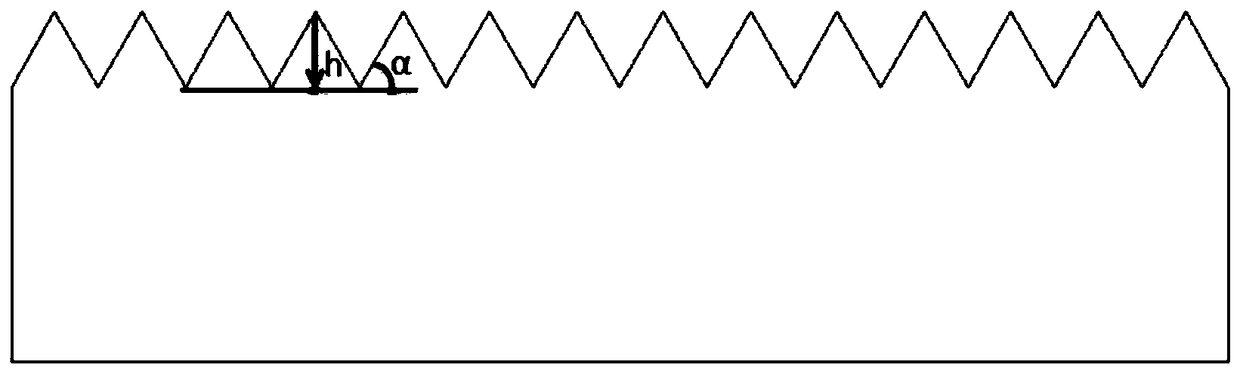

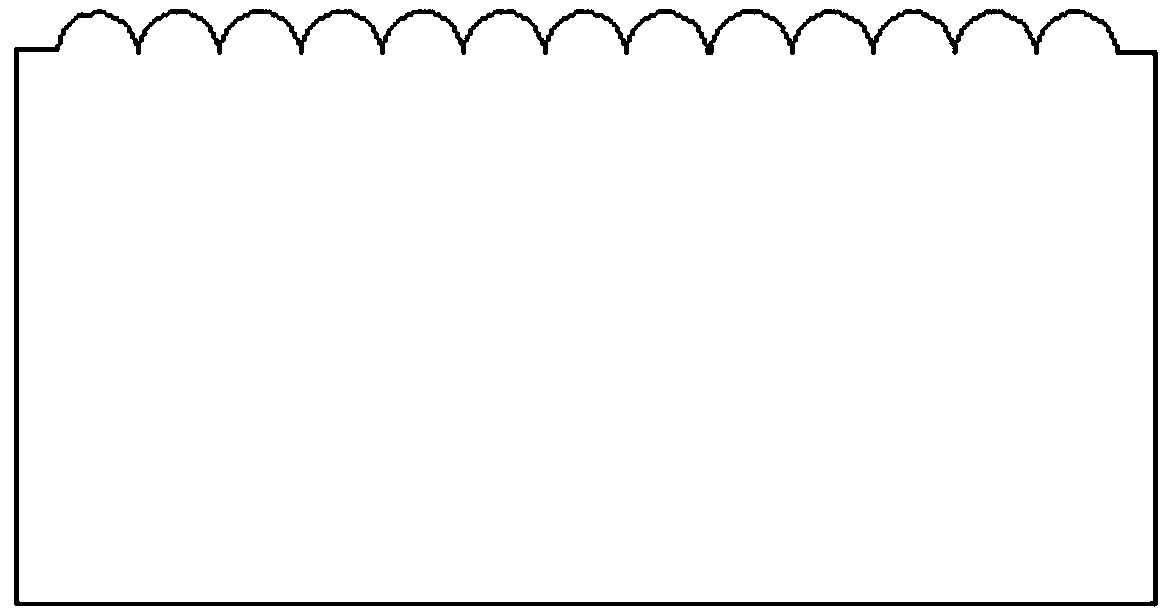

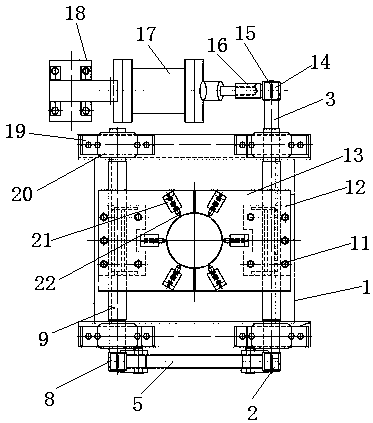

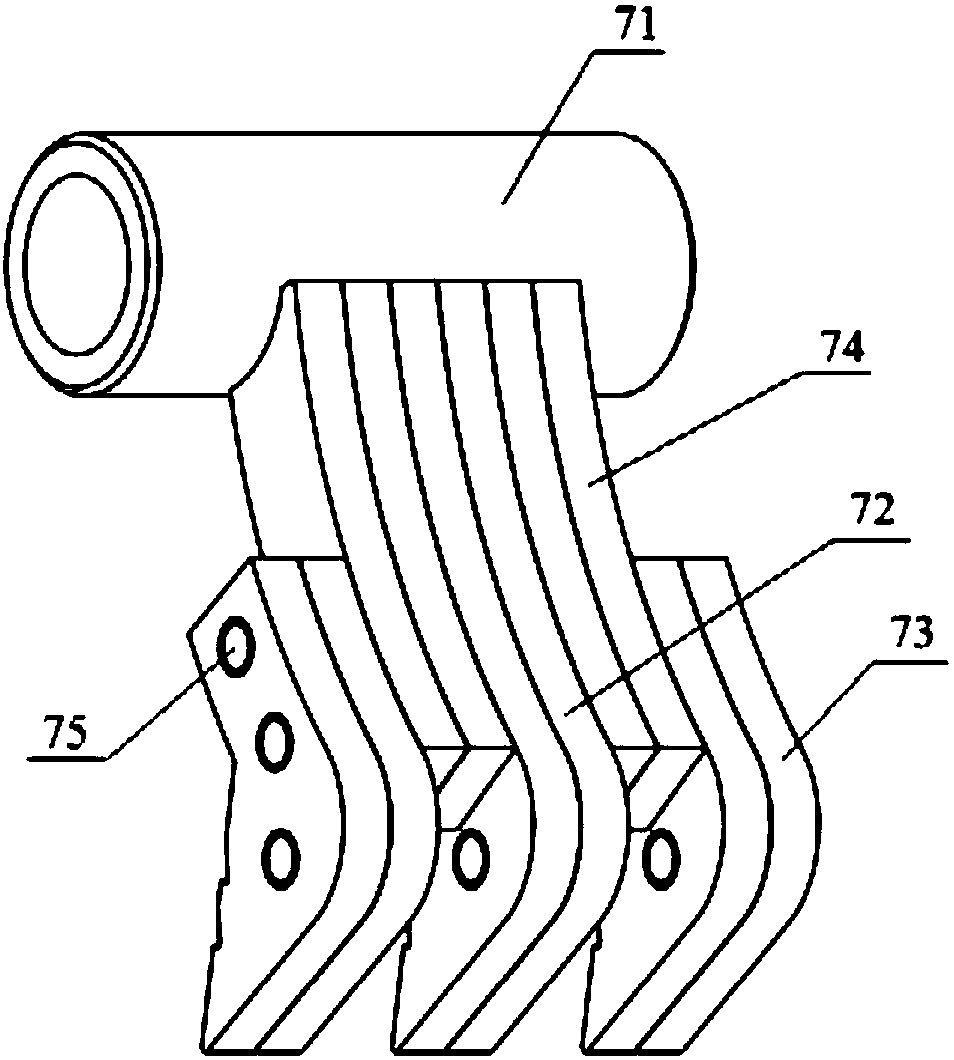

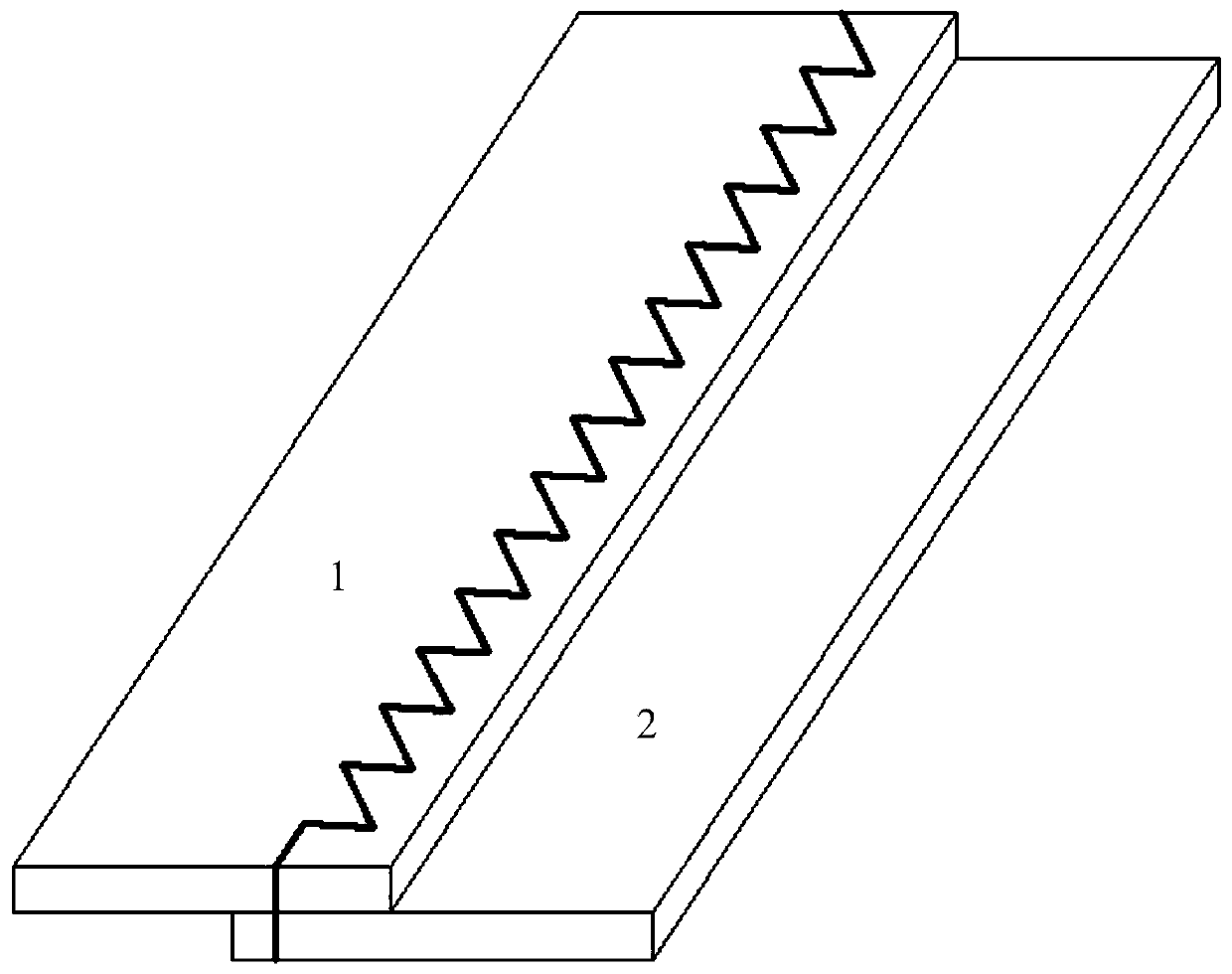

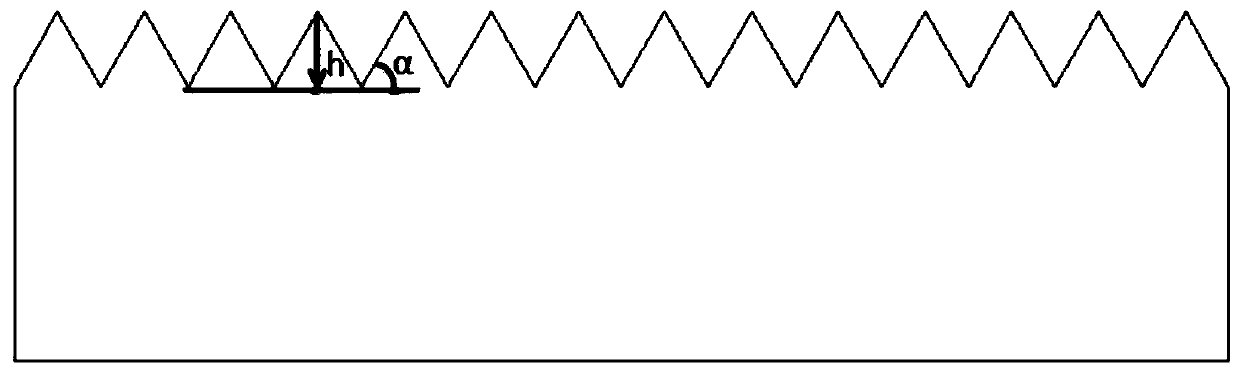

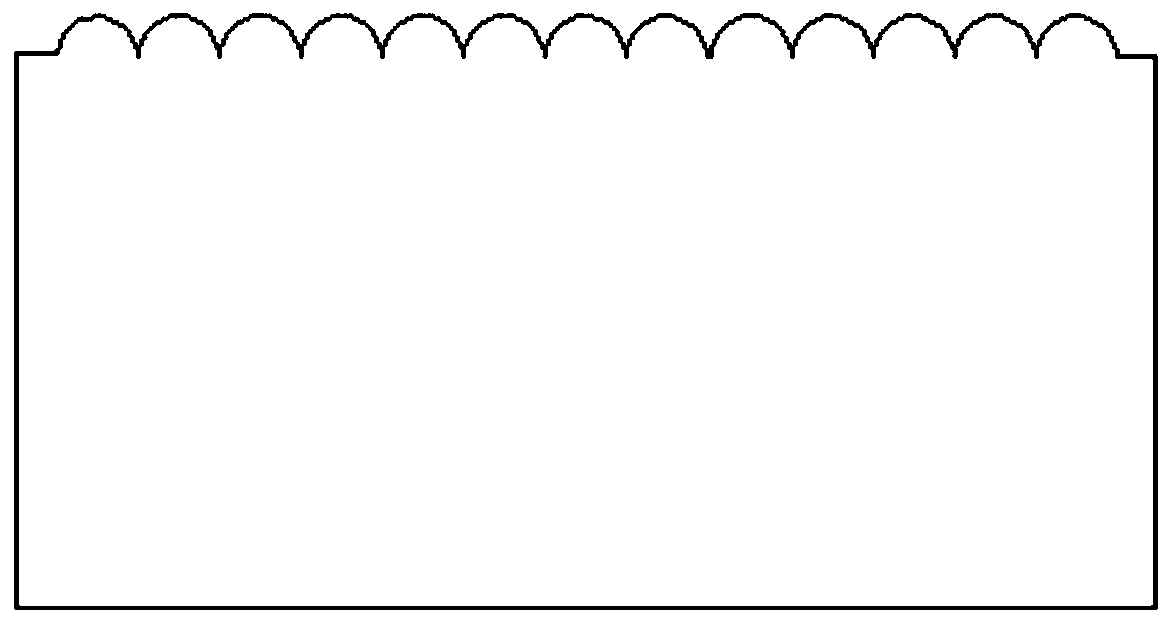

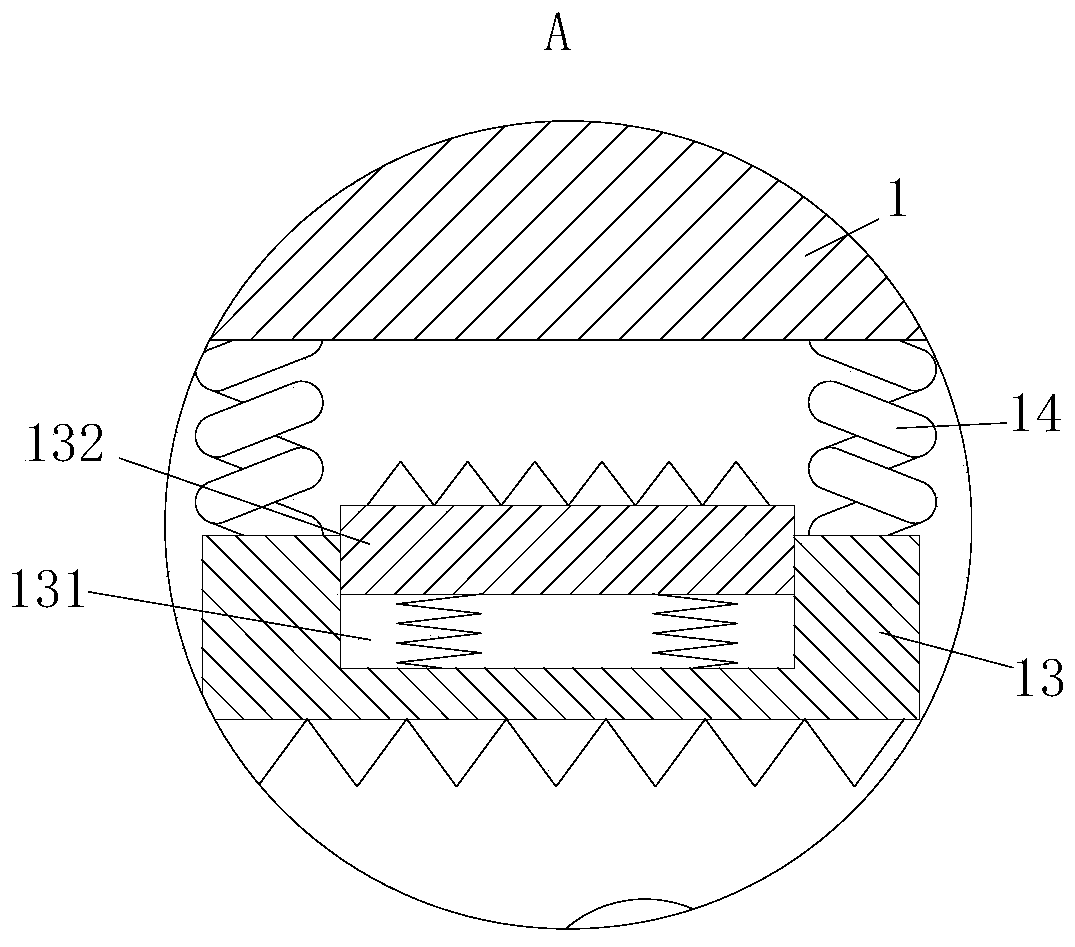

Titanium-steel dissimilar metal structure and manufacturing method thereof

ActiveCN108817647AHigh strengthHigh tensile strengthWorkpiece edge portionsNon-electric welding apparatusRelative motionEngineering

The invention provides a titanium-steel dissimilar metal structure and a manufacturing method thereof. The meshing-corresponding sawtooth structure with high integrating degree is obtained by a stacking-and-lapping mode; a composite plate is obtained by meshing-connection; and high-quality welding of titanium-steel dissimilar metal is achieved by a stirring-friction welding method. The influence on the performance of a dissimilar metal stirring-friction welding connector by deviation is not necessarily to be considered; and asymmetry of a forward side and a backward side in the traditional butt joint process is eliminated. The sawtooth meshing structure is adopted, and therefore action of welding force on materials during the welding process is improved to assist material smashing, the linear contact area of the dissimilar metal is increased, relative movement distance of metal atoms is shortened so that more atoms can move under the same energy, the mutual flow and mutual mixing capacity of the dissimilar metal materials can be improved, the problem of nonuniform connector tissue mixing is avoided, interlocking mixing of weld joint materials is improved, and strength of the connector is greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for recycling and utilizing glutamic acid fermentation waste bacteria

InactiveCN106946976AAvoid pollutionHigh purityFood processingAnimal feeding stuffMicroorganismMicrobiological Techniques

The invention belongs to the technical field of microbiology, and discloses a method for recycling and utilizing glutamic acid fermentation waste bacteria. The method comprises the following steps of (1) centrifuging; (2) stoving and smashing; (3) salt treatment and ultrasonic treatment; (4) hydrolyzation; (5) decolouring and centrifuging; (6) filtering; (7) evaporating and drying; and (8) preparation of fodder. The preparation method is used for preparing oligopeptide products and fodder products, thereby increasing the industrial added value.

Owner:卢松

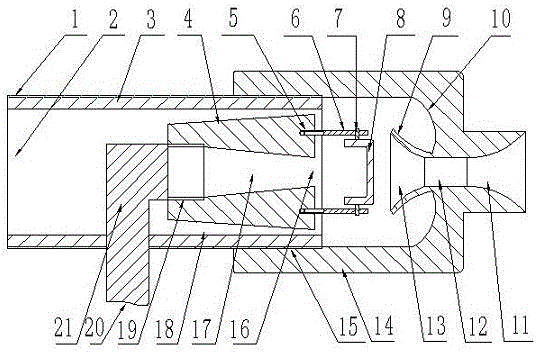

Ultrasonic efficient atomization device of water currents under narrow-slit airflow oscillation stirring

The invention discloses an ultrasonic efficient atomization device of water currents under narrow-slit airflow oscillation stirring. The device comprises a liquid-air leading shell and an atomization device generation shell; a liquid-air leading valve element is arranged in the liquid-air leading shell; an airflow gradual shrinking narrow-slit channel is formed in the outer side of the valve element; a center through hole of the liquid-air leading valve element is a jet water gradual shrinking channel, and a jet water outlet at the tail part is aligned with a water current ultrasonic oscillation cavity; an airflow self-exciting oscillation cavity is formed in the tail end of the atomization device generation shell; a horn-shaped airflow baffle plate is arranged in the center of the airflow self-exciting oscillation cavity; a water mist gradual shrinking channel is formed in the airflow baffle plate; and the water mist gradual shrinking channel, a water mist guide channel and a water mist jet outlet are smoothly transited and connected. An air flow enters the airflow self-exciting oscillation cavity after being accelerated by the airflow gradual shrinking narrow-slit channel; and the airflow baffle plate and the airflow self-exciting oscillation cavity are matched to form an airflow self-exciting oscillation field so as to successfully realize efficient liquid atomization. The device has the advantages of high atomization efficiency and simple structure, and is also suitable for efficient atomization of other liquid.

Owner:TAIYUAN UNIV OF TECH

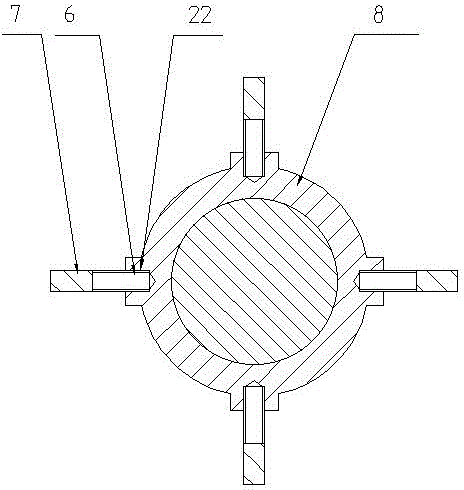

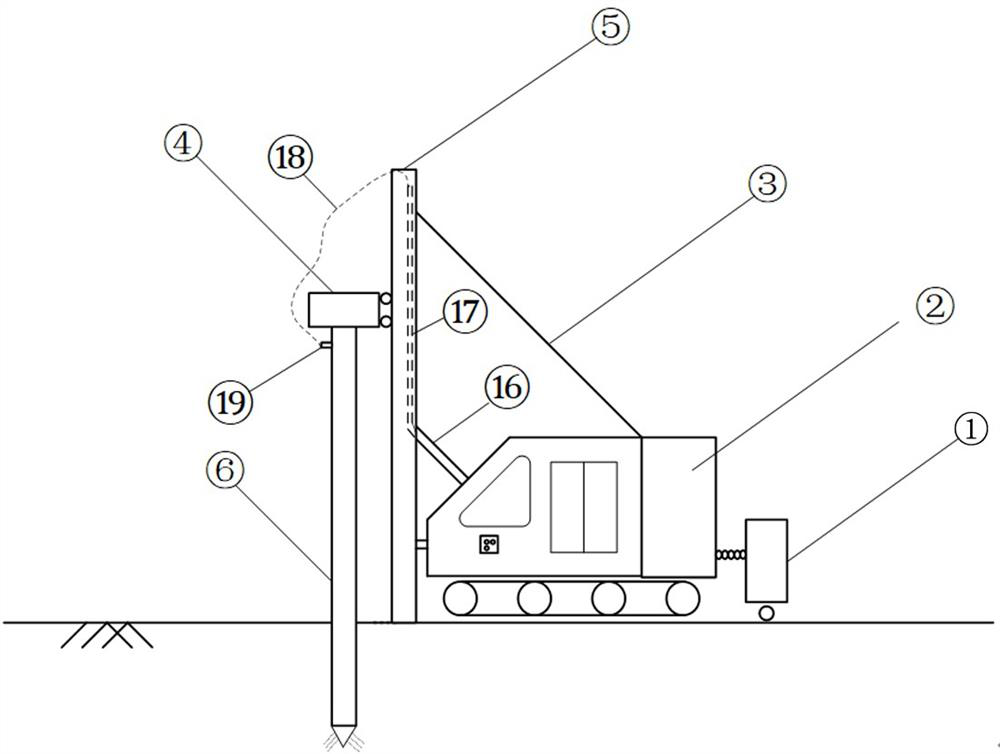

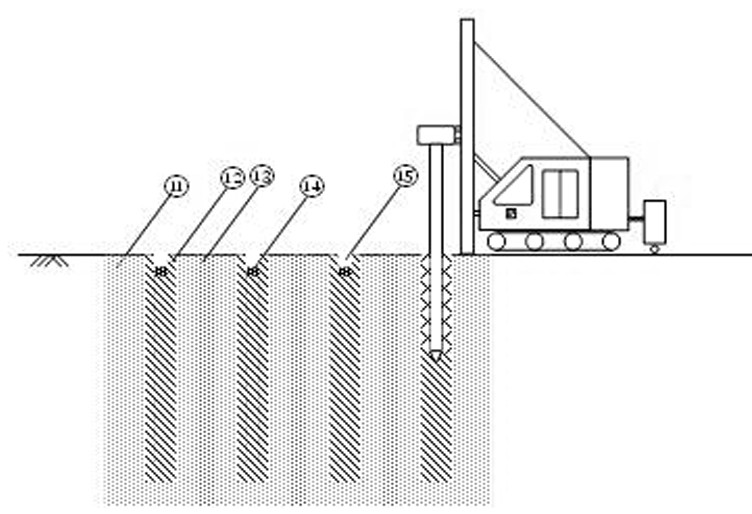

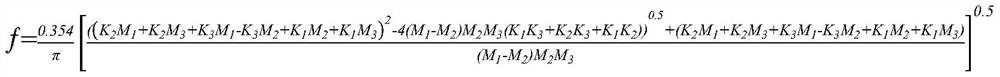

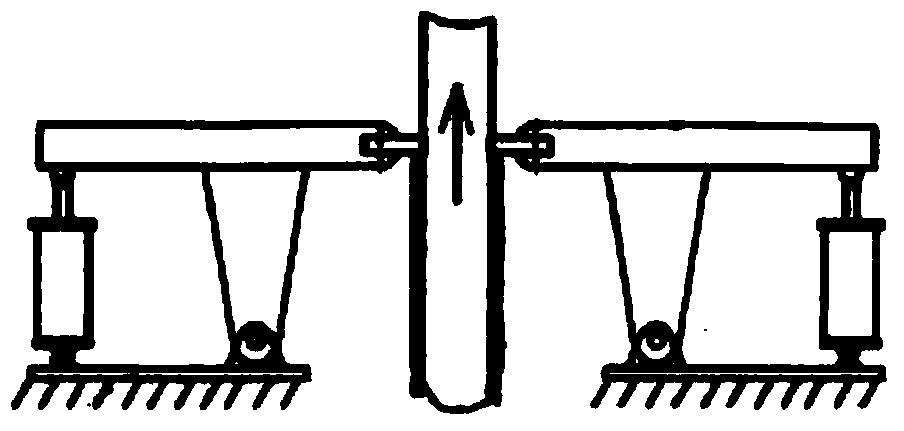

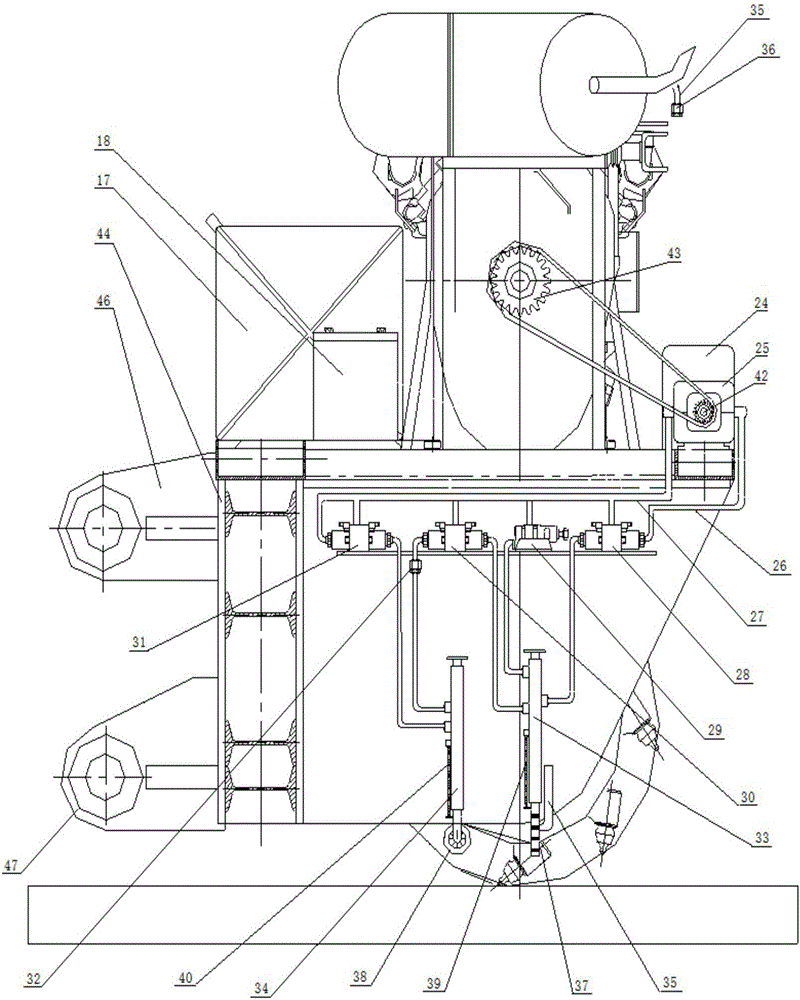

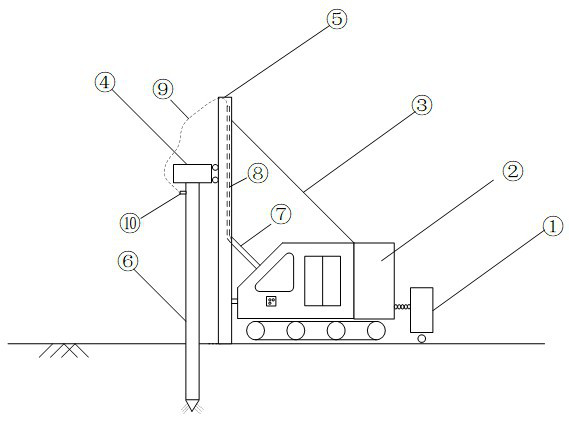

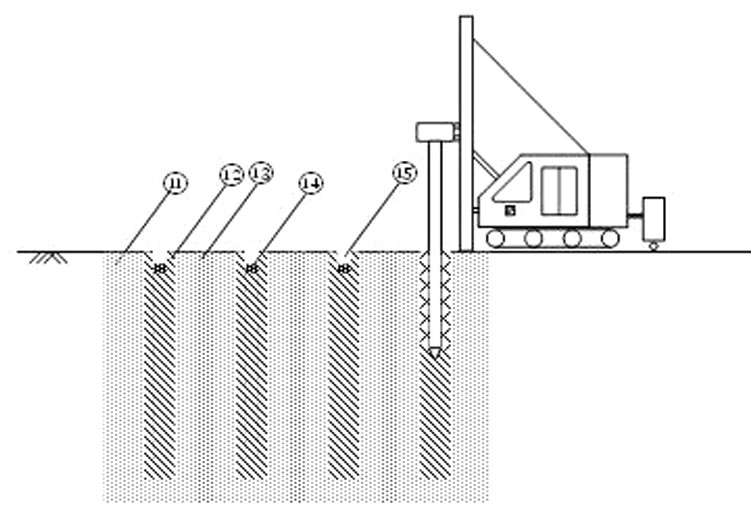

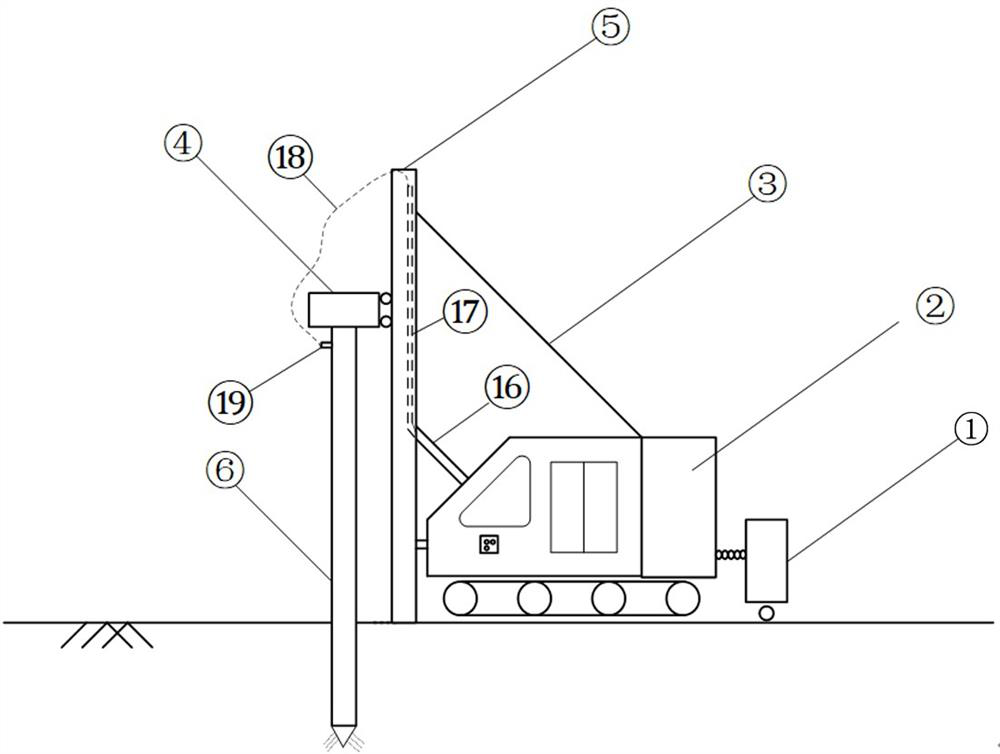

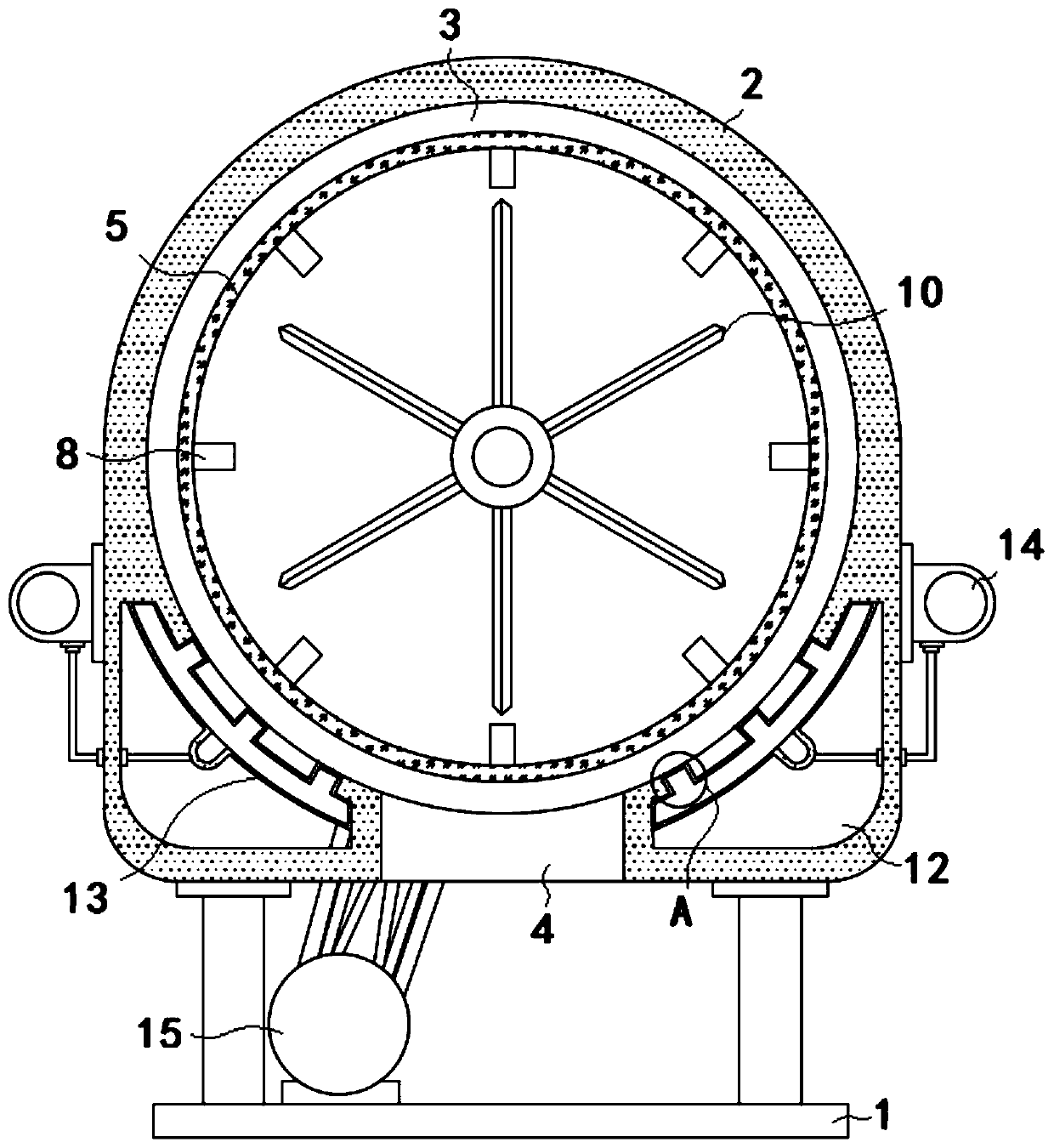

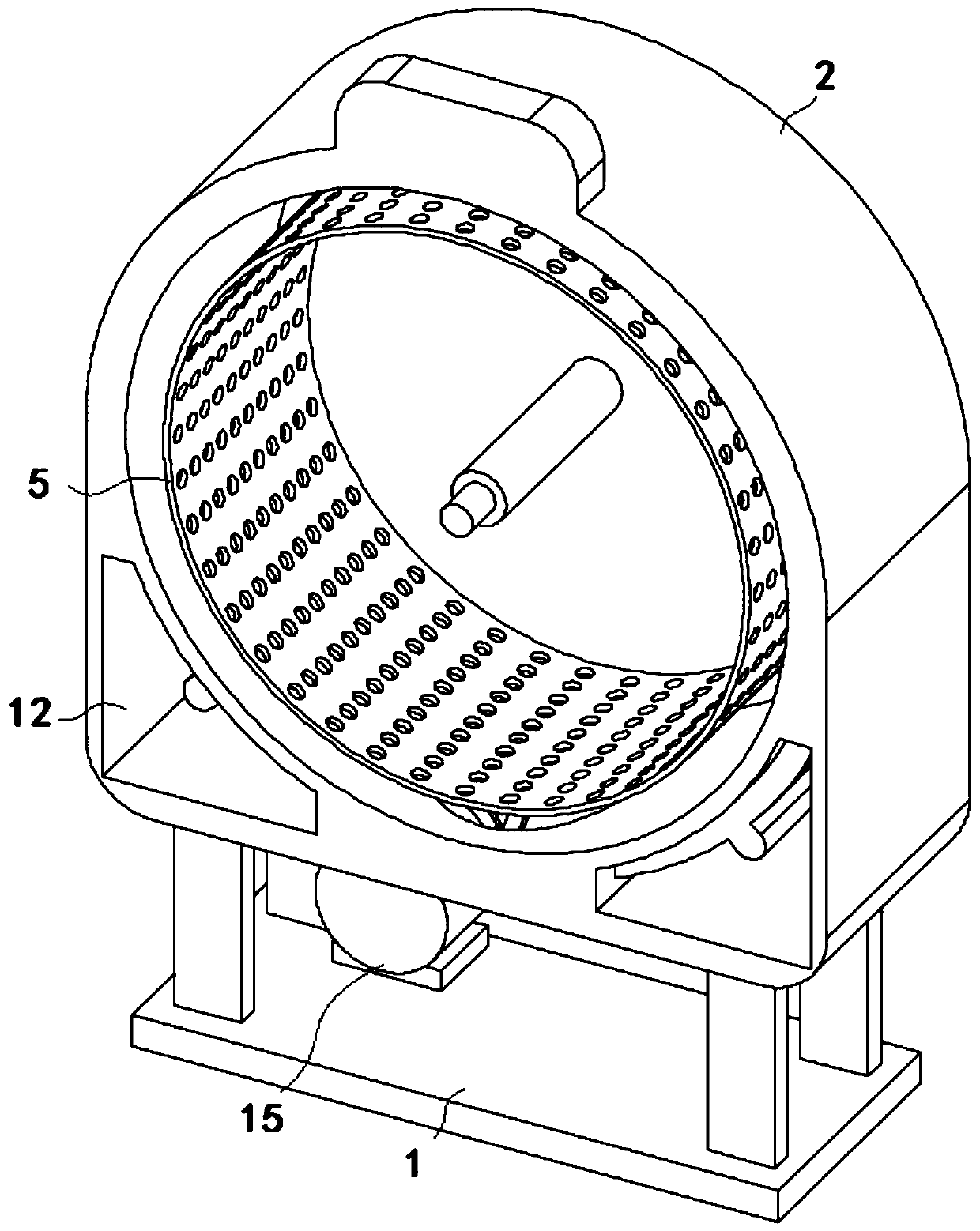

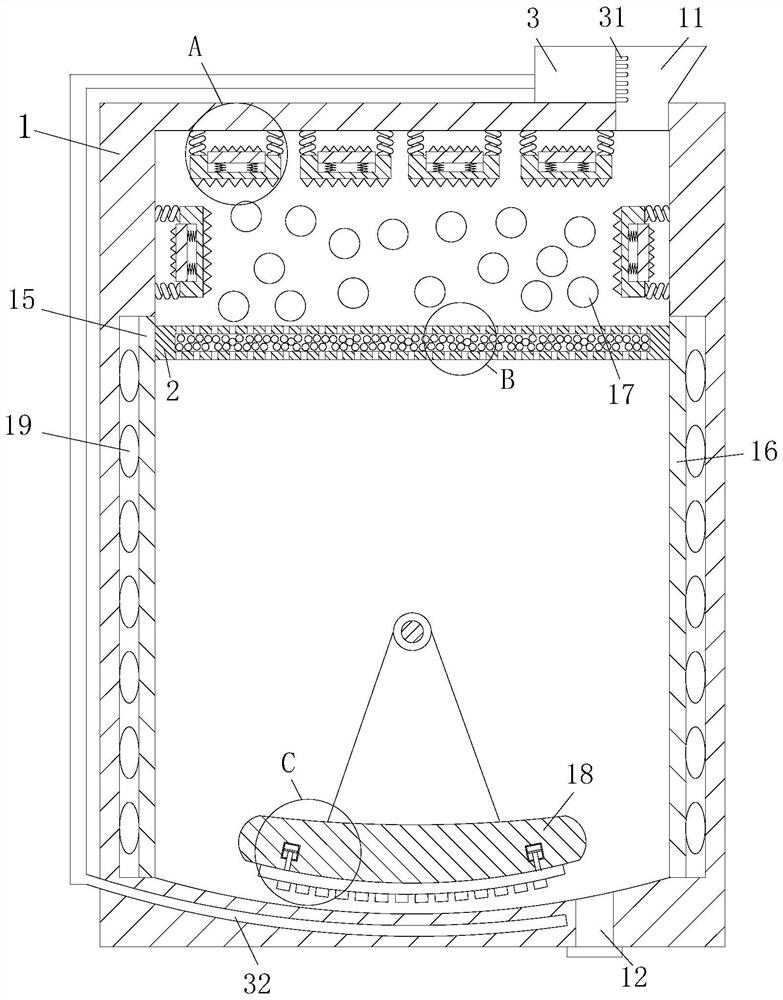

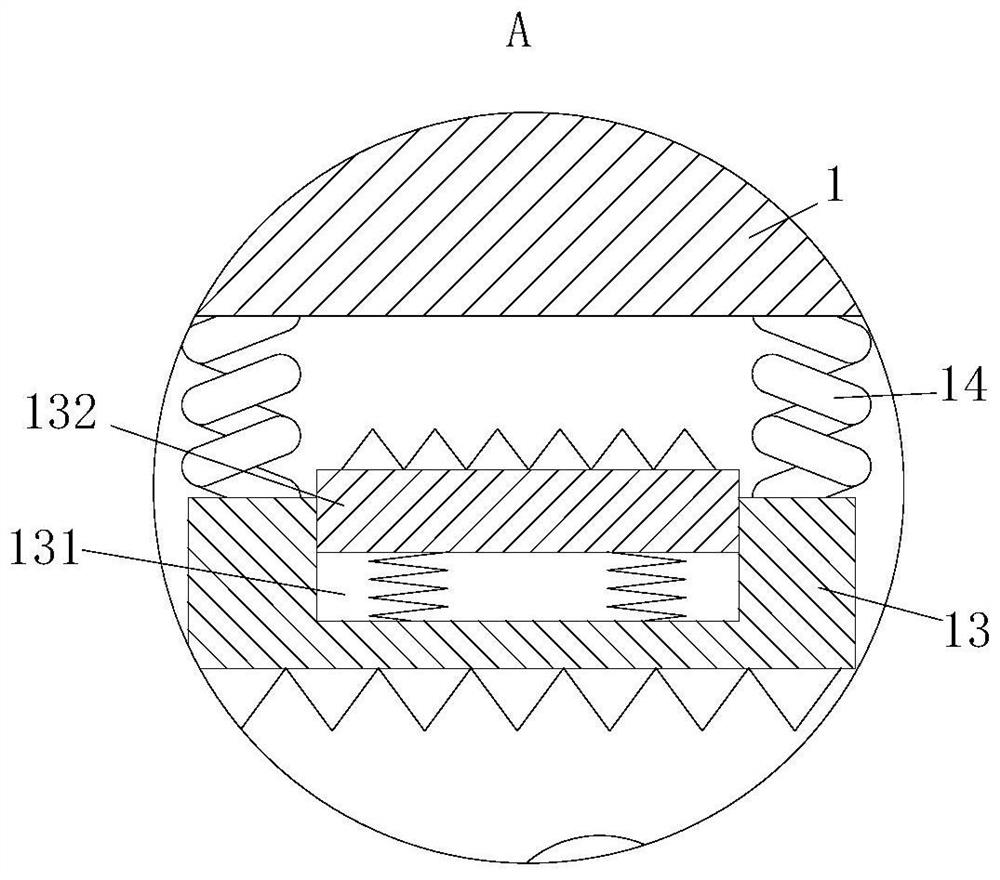

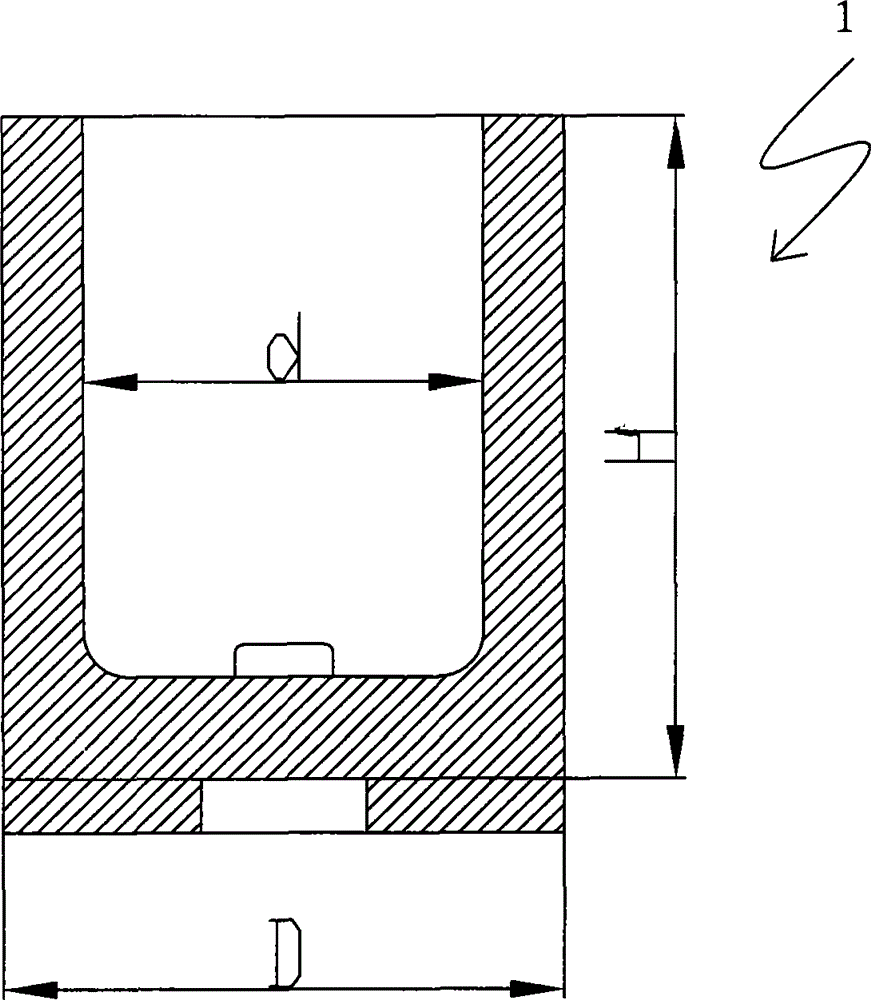

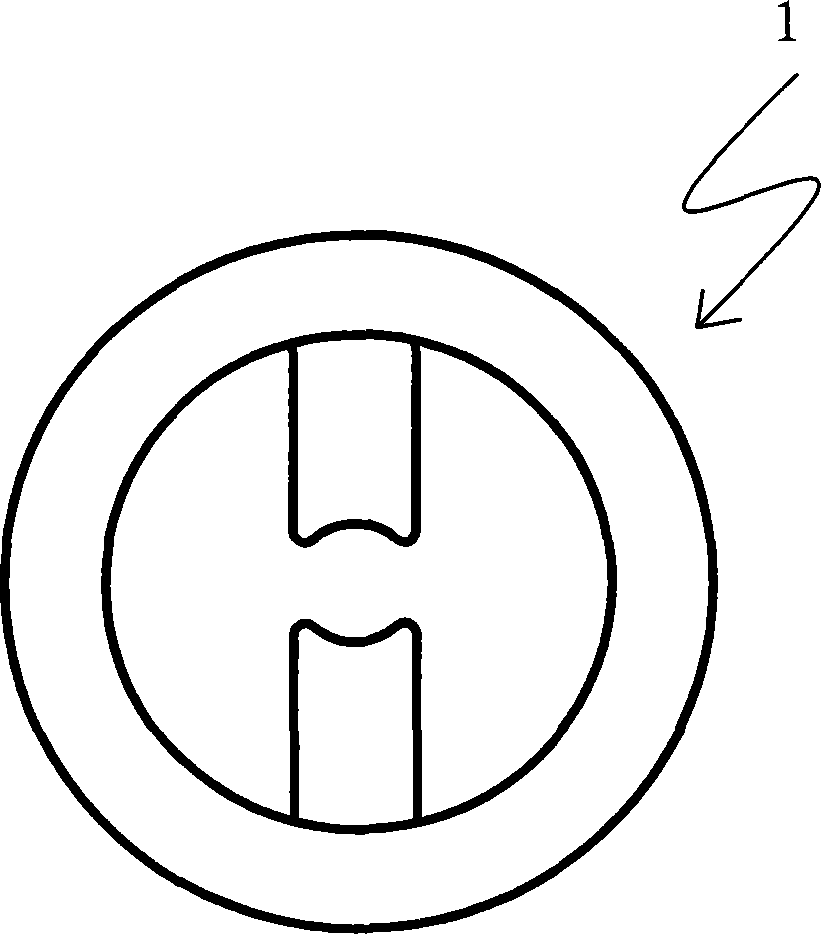

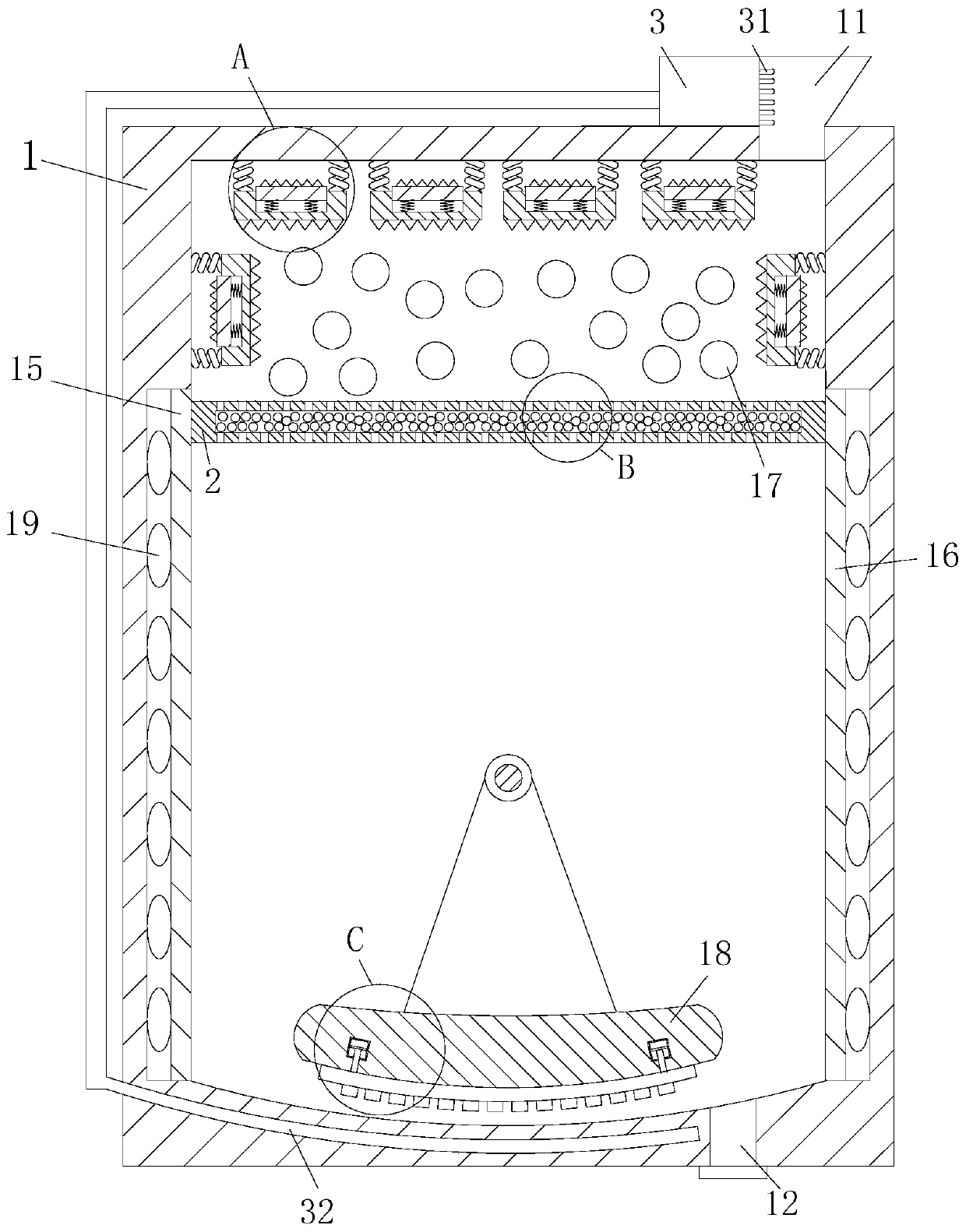

Device and method for densely reinforcing miscellaneous fill foundation through deep resonance

The invention provides a device and a method for densely reinforcing a miscellaneous fill foundation through deep resonance. The method comprises the steps that after a vibrating rod is sunk into a soil body, the frequency of a vibrating hammer is adjusted to the resonance frequency of a vibrating rod-soil system, vibration energy is effectively transmitted to deep miscellaneous fill through the resonance amplification principle, and a miscellaneous fill resonance dense area is formed; and a solidifiable slurry and miscellaneous fill mixing area playing an auxiliary reinforcing role is added, the vibrating hammer drives the vibrating rod to freely fall to compact a compaction area formed by loose soil bodies in vibrating holes, and the miscellaneous fill foundation is jointly reinforced. The defects that a traditional method for reinforcing the deep miscellaneous fill is poor in effect, low in economic benefit, complex in construction technology and the like are effectively overcome.

Owner:ZHENGZHOU UNIV

Method for enzymatically extracting rhodomyrtus tomentosa anthocyanidin by means of ultrasonic waves assisting in biological compound enzyme

InactiveCN109022513AHelp brokenEasy extractionOrganic chemistryFermentationRHODOMYRTUS TOMENTOSA FRUITUltrafiltration

The invention discloses a method for enzymatically extracting rhodomyrtus tomentosa anthocyanidin by means of ultrasonic waves assisting in a biological compound enzyme. According to the method, firstly, rhodomyrtus tomentosa fruits are mashed into pulp, then the biological organized enzyme is added for enzymolysis, then through ultrasonic wave assistant extraction and centrifugation, supernate iscollected, ultrafiltration and concentration are conducted, and finally, a concentrated solution is subjected to spray drying to obtain the rhodomyrtus tomentosa anthocyanidin; the biological organized enzyme is a compound of acid cellulase, glucoamylase and tannase; meanwhile, blueberry anthocyanidin extracted by means of biological organized enzyme enzymolysis and ultrasonic wave assistant extraction is high in purity, low in cost and simple and convenient to operate; by means of citric acid, the stability of the anthocyanidin is improved, and anthocyanidin loss caused by oxidation of polyphenol and enzymes is effectively controlled; finally, the efficiency of extracting the anthocyanidin reaches 90% or above.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

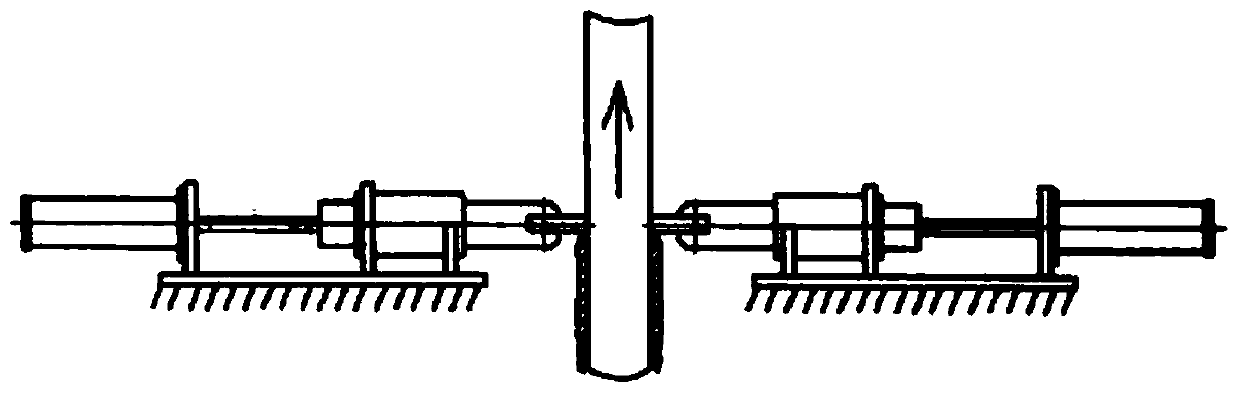

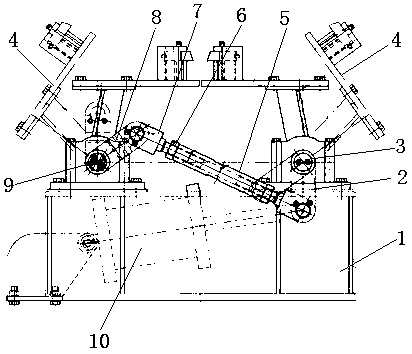

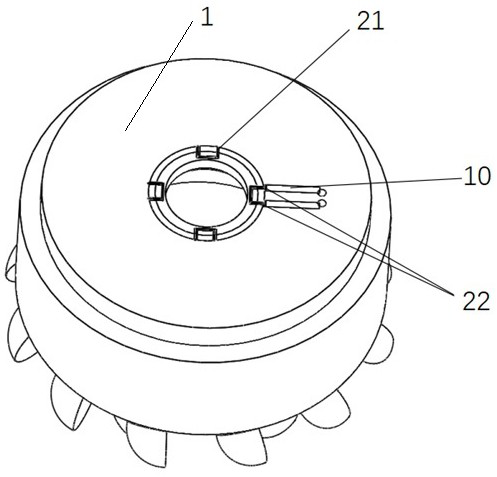

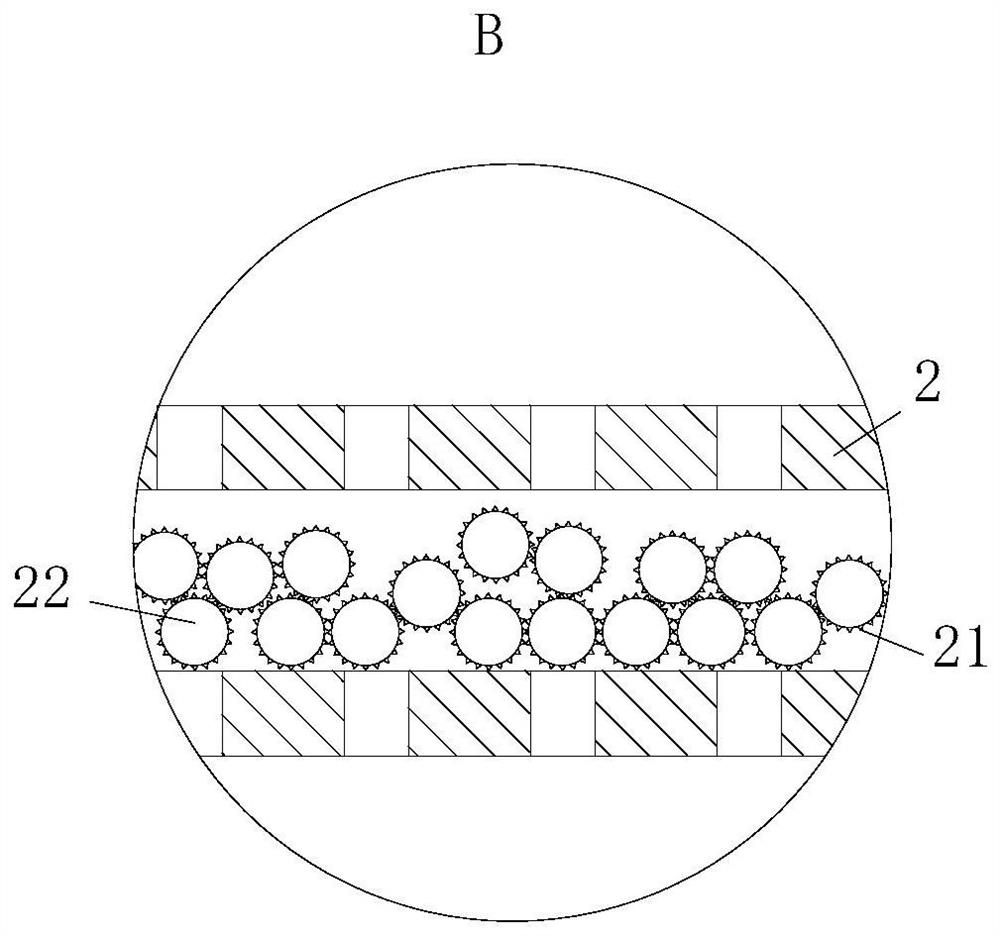

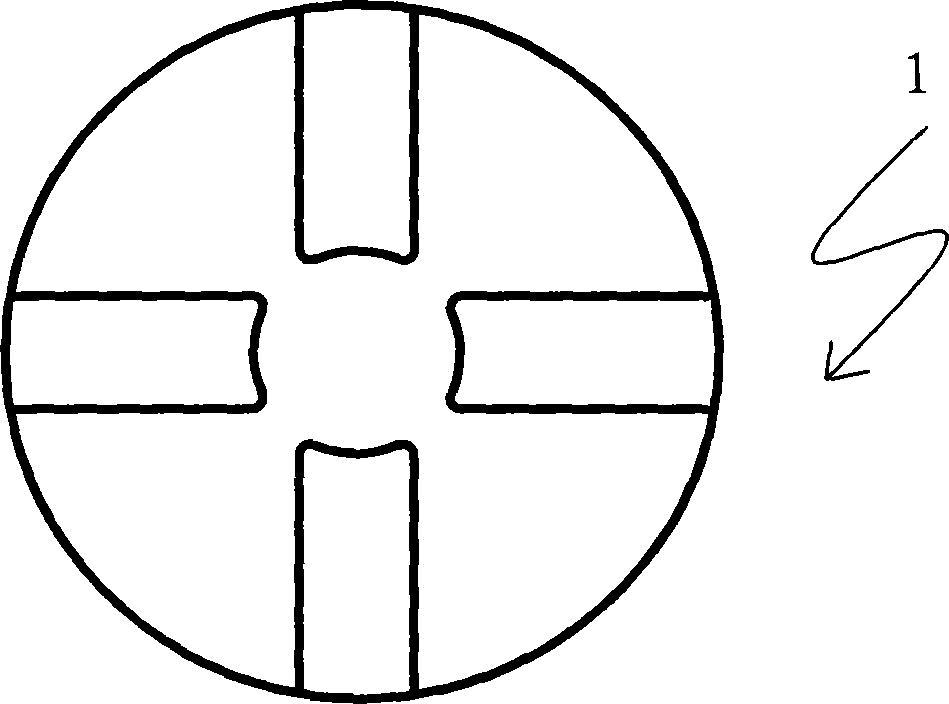

Ratchet wheel type oxygen lance slag scraper

ActiveCN103993128AImprove scraping effectAvoid damage to equipmentManufacturing convertersProcess efficiency improvementRatchetWire rope

The invention discloses a ratchet wheel type oxygen lance slag scraper which can improve a slag scraping effect and prolong service life. The ratchet wheel type oxygen lance slag scarper comprises two symmetrically arranged cylinders, two symmetrically arranged bearing block groups, two symmetrically arranged slag scraping ratchet wheel groups, wherein the cylinders are hinged to a cylinder support, a connecting shaft is arranged in each of the two bearing block groups, each slag scraper ratchet wheel group at least comprises two slag scraper ratchet wheels, and a pin shaft is in clearance fit with the slag scraping ratchet wheels. The ratchet wheel type oxygen lance slag scraper has the advantages that multiple slag scraper ratchet wheels are arranged, so that multiple force bearing points are formed on steel slag on the outer wall of an oxygen lance, and therefore the steel slag can be crushed very well, the slag scraping effect is improved; in addition, since the slag scraper ratchet wheels can rotate, the slag scraper ratchet wheels rotate when too much steel slag is adhered, fracture of a steel wire rope or damage of equipment can be avoided, and service lives of related equipment such as the ratchet wheel type oxygen lance slag scraper and the oxygen lance are prolonged.

Owner:HUATIAN ENG & TECH CORP MCC

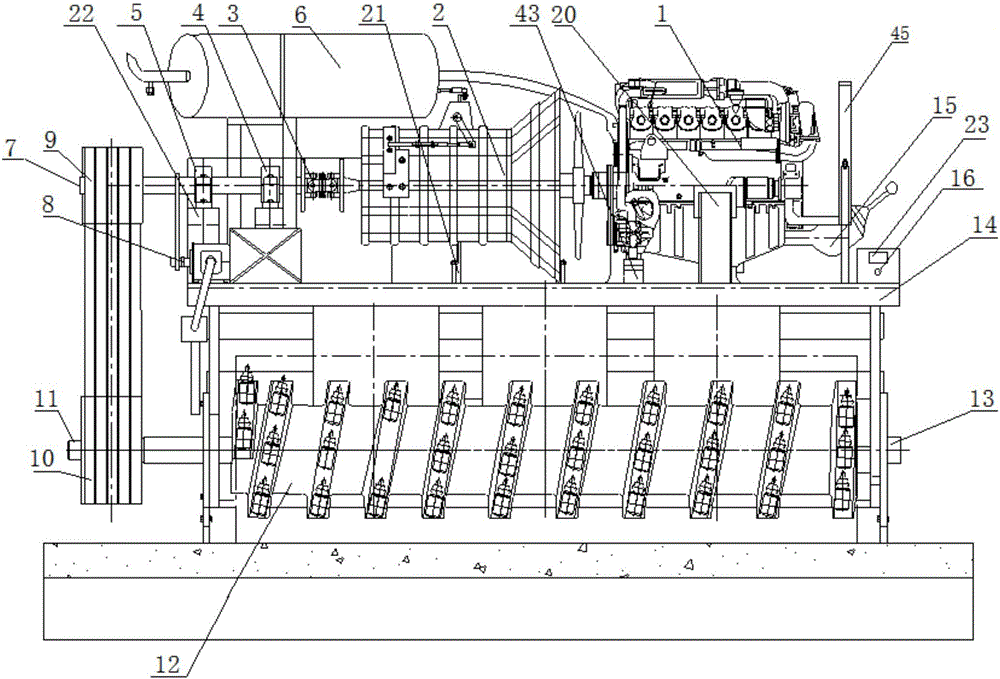

Road de-icing device and de-icing method suitable for loader

The invention relates to a road de-icing device and de-icing method suitable for a loader, which belongs to the technical field of road de-icing and particularly relates to a detachable de-icing device which is conveniently mounted on the loader. The detachable de-icing device comprises a de-icing mechanism and an ice layer thickness detecting mechanism, the advance speed of the loader and the rotation speed of a milling drum can be automatically adjusted according to the thickness of an ice layer, the de-icing thickness range is large, and the mechanical motion of the ice layer thickness detecting mechanism and the mechanical motion of a limiting device can be automatically controlled by a hydraulic device, thereby realizing intelligent measurement for the road icing thickness. The loader used by the invention is a common operation machine of the road maintenance department, thereby having wide scope of popularization; the loader is used as a power source, thereby avoiding the problem of relatively high cost of a vehicle body of a dedicated de-icing vehicle. Meanwhile, an icebreaking device can be separated from the loader, so that other applications of the loader are not influenced outside the operational period.

Owner:WUHAN UNIV OF TECH

Oxygen lance slag scraper

InactiveCN107828934AIncrease stiffnessOptimized structural formManufacturing convertersProcess efficiency improvementSlagFixed frame

The invention provides an oxygen lance slag scraper. The oxygen lance slag scraper comprises a fixed frame which is symmetrically provided with a driving shaft and a driven shaft; the two ends of thedriving shaft are provided with a first connection rod and a second connection rod which rotate around the axis of the driving shaft; one end of the driven shaft is provided with a third connection rod which rotates around the axis of the driven shaft; the driving shaft is connected with a driving mechanism through the first connection rod, and the second connection rod is connected with the thirdconnection rod through a connection rod assembly; and the driving shaft and the driven shaft are each provided with a scraper blade assembly, and the two scraper blade assemblies are symmetrically distributed. According to the oxygen lance slag scraper, synchronous starting and stopping of the scraper blade assemblies can be achieved through a plane four-rod mechanism, connection rod operation isstable, the rigidity of the slag scraper is improved, the structural style of the slag scraper is optimized, and the service life of the slag scraper is prolonged; and meanwhile, by arranging a plurality of scraper blades, steel slag on the outer wall of an oxygen lance has a plurality of force bearing points, thus, the steel slag can be crushed more easily, and the slag scraping effect is improved.

Owner:WISDRI ENG & RES INC LTD

Treatment process of waste bacteria produced during amino acid fermentation

ActiveCN107011409AIncrease the speed of diffusionPromote ruptureFood processingAnimal feeding stuffAmino acid fermentationBacteria

The invention belongs to the technical field of amino acid production, and discloses a treatment process of waste bacteria produced during amino acid fermentation. The treatment process comprises the following steps: 1) drying and crushing; 2) performing salt treatment and ultrasonic treatment; 3) hydrolyzing; 4) adsorbing and centrifuging; 5) filtering; 6) evaporating and drying; 7) preparing feed. By the treatment process provided by the invention, a peptide product and a feed product with relatively high purity can be prepared, and waste of a bacterial raw material is avoided.

Owner:内蒙古阜丰生物科技有限公司

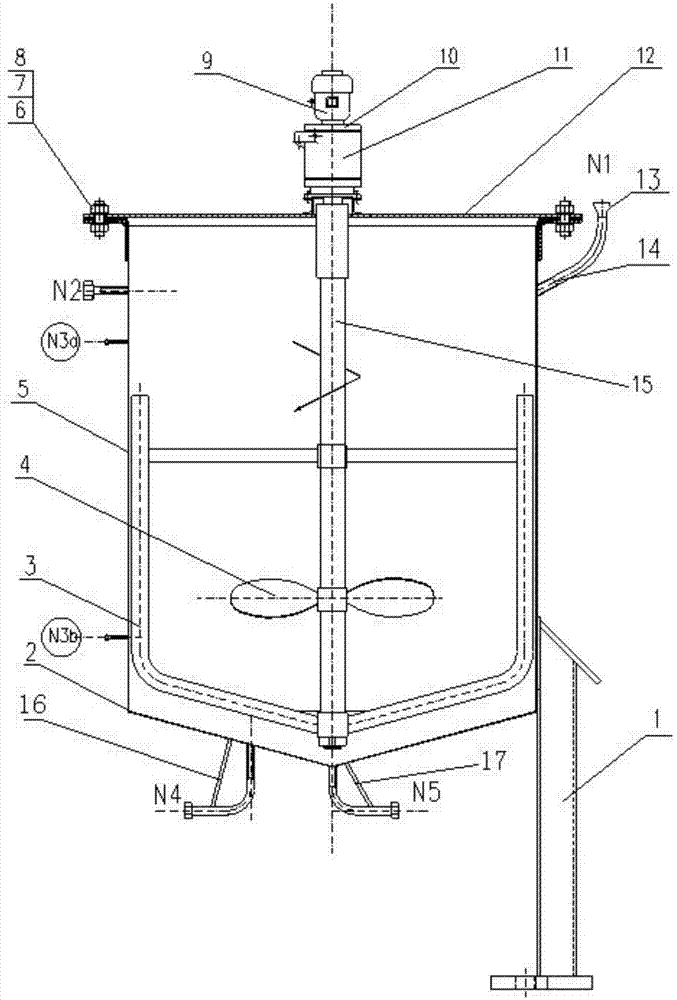

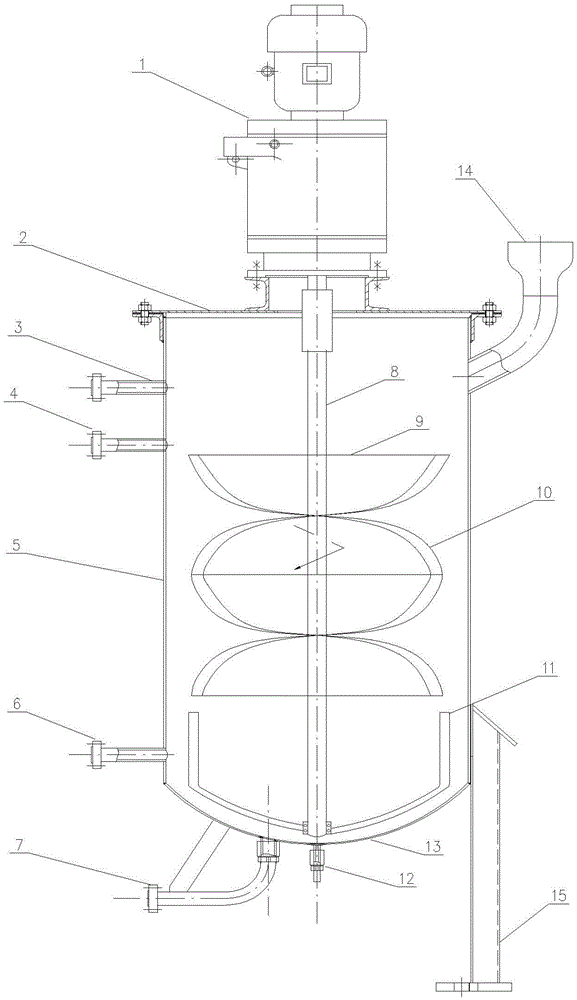

Copper hydroxide cleaning device

InactiveCN103934233AIncreased turbulenceImprove cleaning efficiencyCopper oxides/halidesCleaning using liquidsParticle flowEngineering

The invention discloses a copper hydroxide cleaning device. The copper hydroxide cleaning device comprises a conical end socket, a conic-bottomed anchor agitator, a turbine agitator, a cylinder body, a motor, a reduction gearbox, an end cap, a reducing pipe, a connecting pipe and a rotary shaft, wherein the end cap is arranged on the top of the cylinder body, the conical end socket is arranged at the bottom of the cylinder body, the sidewall of the upper portion of the cylinder body is provided with a copper hydroxide pug inlet and a cleaning water inlet, and the bottom of the conical end socket is provided with a discharge port and a sewage draining outlet. The motor and the reduction gearbox are arranged on the upper portion of the end cap. The motor is connected with the rotary shaft extending into the cylinder body through the reduction gearbox. The turbine agitator and the conic-bottomed anchor agitator are sequentially arranged on the rotary shaft from top to bottom. The bottom of the conic-bottomed anchor agitator is attached to the inner wall of the conical end socket. The copper hydroxide cleaning device is used for cleaning copper hydroxide and improving the cleanliness of the copper hydroxide; in addition, other particle flow can be adopted to replace copper hydroxide pug, and corresponding cleaning agents can be adopted, so cleaning of the particle flow can be achieved.

Owner:XI AN JIAOTONG UNIV

Extraction method for thalli produced in amino acid fermentation

The invention discloses an extraction method for thalli produced in amino acid fermentation, belonging to the technical field of production of amino acids. The extraction method comprises the following steps: step 1) drying and crushing; step 2) salt treatment and ultrasonic treatment; step 3) hydrolysis; and step 4) evaporation and spray granulation. To reduce cost for raw materials, the extraction method does not use expensive enzyme preparations for treatment; and thallus protein powder with comprehensive nutrient composition is prepared, and the thallus protein powder can be used for replacing yeast extract and has better fermentation and culture effect.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Method for extracting phycocyanin from cyanobacteria

ActiveCN110272486AImprove stabilityHigh yieldMicroorganism lysisDepsipeptidesPhylum CyanobacteriaFiltration

The invention relates to the technical field of protein extraction, in particular to a method for extracting phycocyanin from cyanobacteria. The method for extracting the phycocyanin from the cyanobacteria comprises the steps that cell disruption, coarse filtration and purification are carried out; and according to the coarse filtration, after products obtained from cell disruption are filtered by a microfiltration membrane of 0.5-1[mu]m, grease and deionized water are sequentially added for mixing, the grease is removed through water-oil separation, and then filtration is carried out by the microfiltration membrane of 0.5-1[mu]m. The method for extracting the phycocyanin from the cyanobacteria has the characteristics of high yield, high purity, high protein stability, short extraction cycle, low cost, simple operation and good resource utilization rate.

Owner:北海生巴达生物科技有限公司

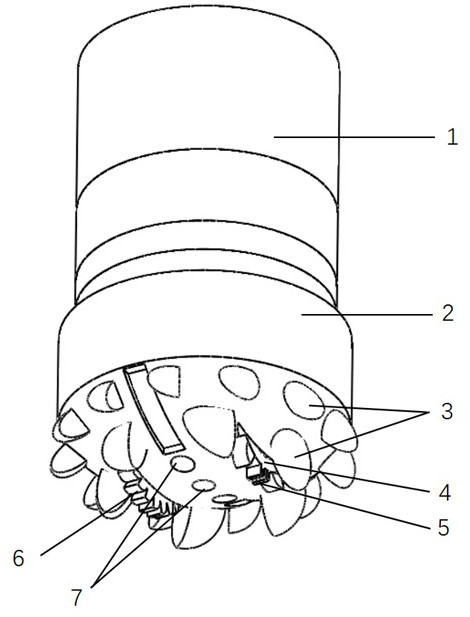

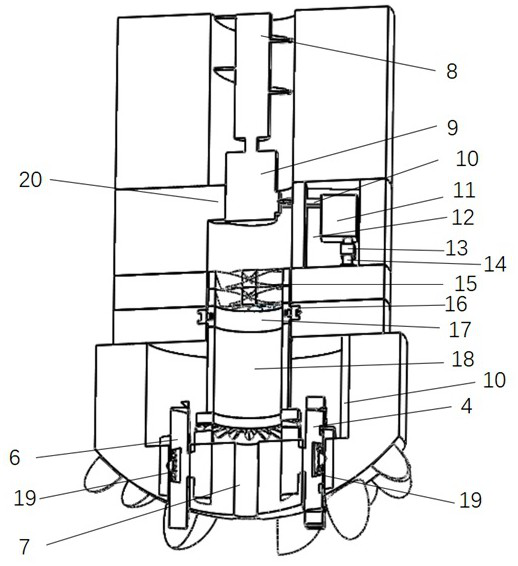

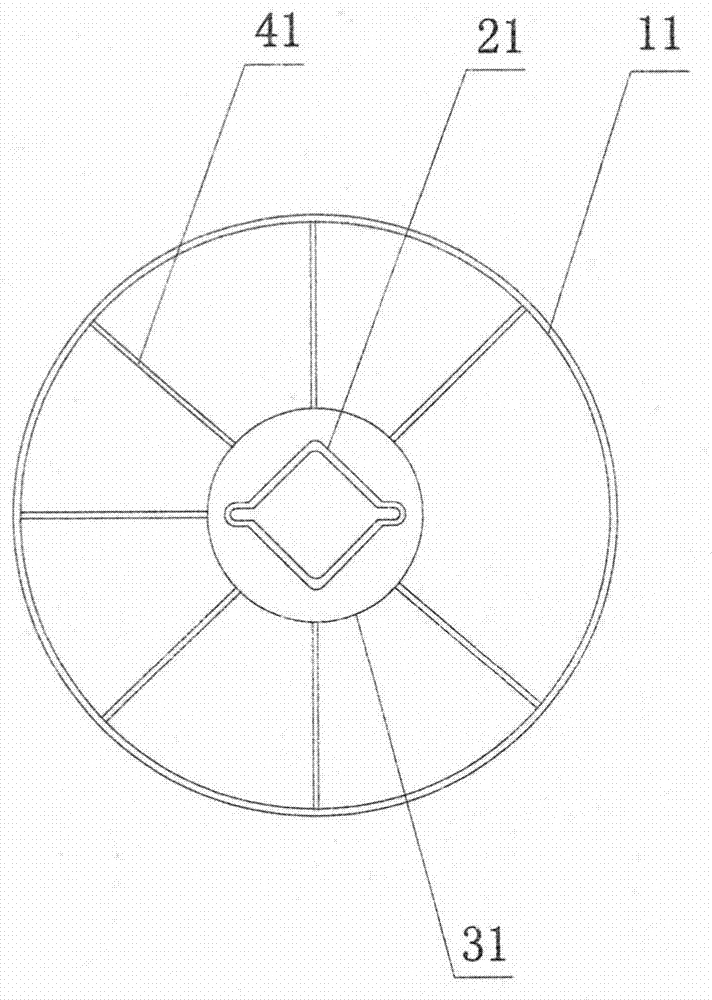

Hydraulically-driven multi-dimensional plasma combined drill bit and well drilling method thereof

PendingCN113187405AOvercome limitationsLow costBatteries circuit arrangementsDrill bitsGear wheelTurbine blade

The invention relates to a hydraulically-driven multi-dimensional plasma combined drill bit and a well drilling method thereof. The hydraulically-driven multi-dimensional plasma combined drill bit comprises a drill rod, a drill bit body, a plasma turntable gear, a plurality of plasma devices, a mechanical cutting gear and a power generator, a slurry turbine is arranged in the drill rod, and the bottom of the slurry turbine is connected with the power generator; the bottom of a cylinder on the outer edge of the turbine blade is fixedly connected with a turntable switch, the turntable switch is provided with a plurality of discharge switches in the circumferential direction, each discharge switch extends into an annular slide rail, a pair of cables also extends into the annular slide rail, and the end parts of the pair of cables are provided with switch electric brushes; and an upper gear is welded to the lower end of the turntable switch, the lower portion of the upper gear is engaged with two connecting gears, the two connecting gears are coaxially fixed to the plasma turntable gear and the mechanical cutting gear respectively, and the plasma turntable gear and the mechanical cutting gear are exposed out of the bottom of the drill bit body. Mechanical cutting and plasma impact are combined for rock breaking, and the rock breaking speed is increased.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Device and method for deep resonant compaction and reinforcement of miscellaneous fill foundation

The device and method for deep resonant compaction and reinforcement of miscellaneous fill foundation, after sinking the vibrating rod into the soil, adjust the frequency of the vibrating hammer to the resonant frequency of the vibrating rod-soil system, and use the principle of resonance amplification to effectively transfer the vibration energy to the deep miscellaneous Filling, forming a resonant compacting area of miscellaneous fillings, plus the mixed area of solidifiable slurry and miscellaneous fillings for auxiliary reinforcement, the vibrating hammer drives the vibrating rod to freely fall to compact the compacted area formed by the loose soil inside the vibrating hole Reinforce miscellaneous fill foundation; effectively solve the shortcomings of traditional methods such as poor effect of reinforcing deep miscellaneous fill, low economic benefits, and complicated construction techniques.

Owner:ZHENGZHOU UNIV

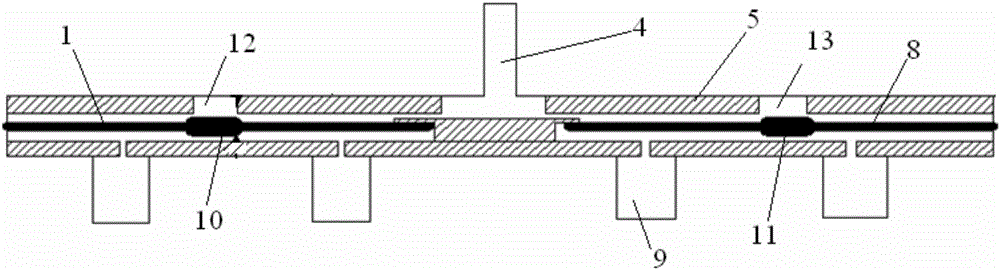

Fuel rail assembly of gasoline engine

InactiveCN106593728ALow kinematic viscosityIncreased turbulence intensityFuel injection apparatusMachines/enginesGasolineViscosity

The invention discloses a fuel rail assembly of a gasoline engine. The fuel rail assembly comprises an oil inlet (4) and an oil channel. Two heaters are arranged in an oil track (5) and extend into an inner cavity of the oil track (5) from the two ends of the oil track (5). The portions, extending into the inner cavity of the oil track (5), of the heaters are each provided with a heater heating body. The heater heating bodies are located at the oil channel. By the adoption of the technical scheme, gasoline is heated before entering an air channel, the kinematic viscosity of gasoline is reduced due to the temperature increase of the gasoline, flowing resistance is reduced, the Reynolds number is increased, accordingly, the fuel turbulence intensity is improved, and pockets of oil are crushed advantageously; and meanwhile, due to continuous rise of the gasoline temperature, the gasoline expands in size, expansion is stacked with pressure spread by an oil pump for oil pumping, the jet pressure is improved indirectly, the jet speed can be increased advantageously, and the atomization effect is improved.

Owner:CHERY AUTOMOBILE CO LTD

Treatment device for plastic needle cylinder of disposable medical syringe

InactiveCN111098432AImprove crushing effectReduce structural strengthPlastic recyclingDrying gas arrangementsSyringeBiomedical engineering

Owner:XUZHOU SHENFENG PRECISION MASCH CO LTD

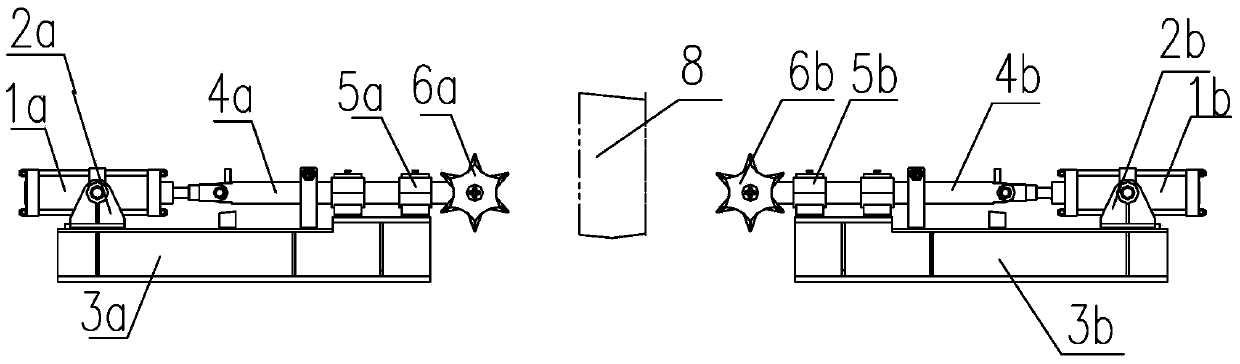

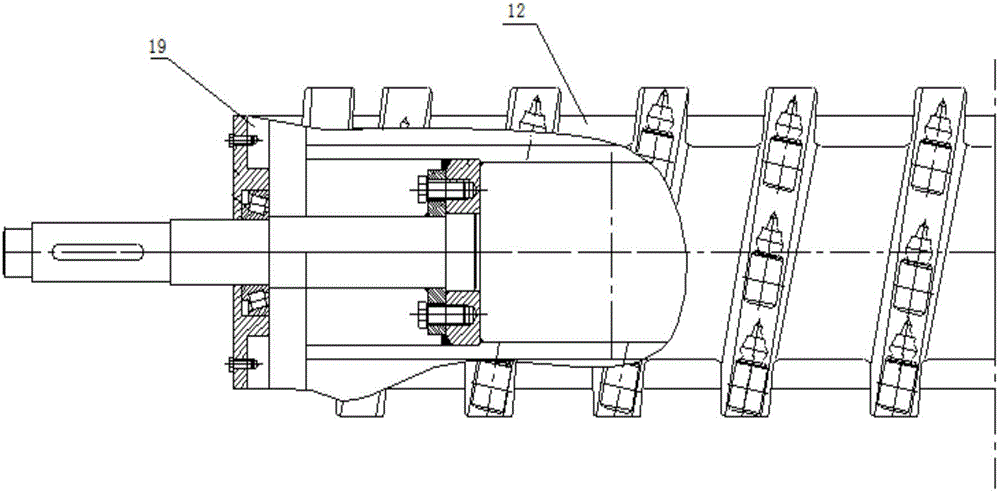

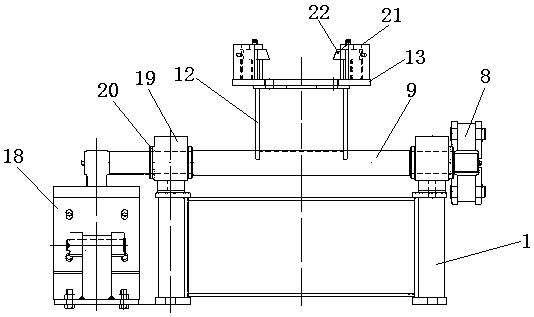

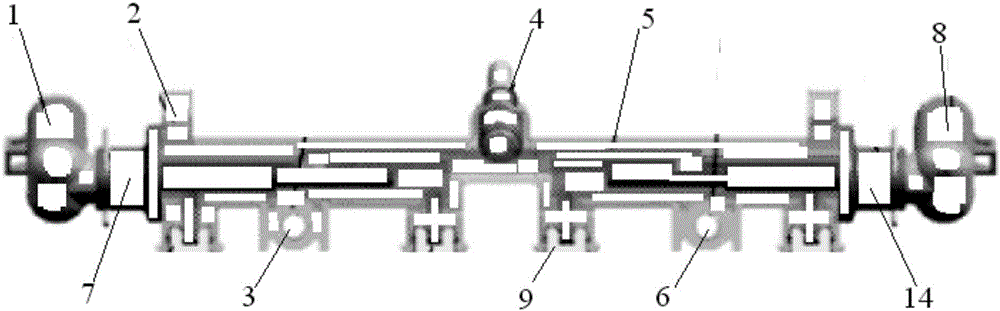

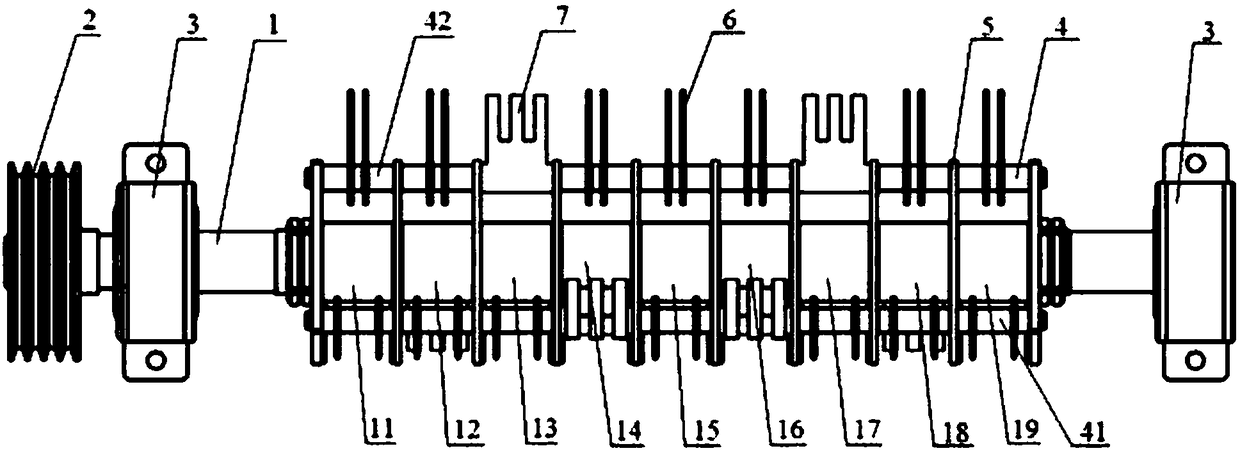

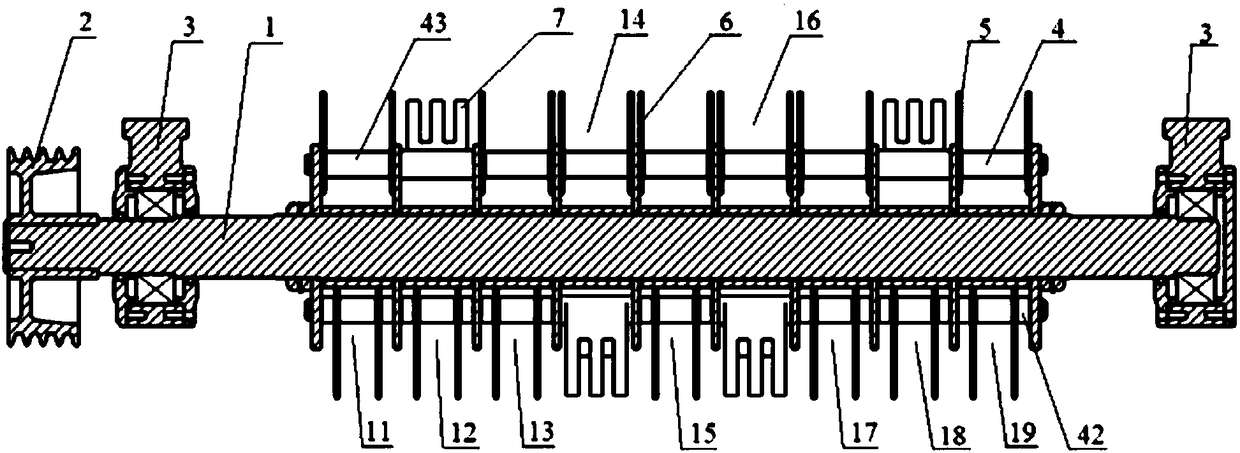

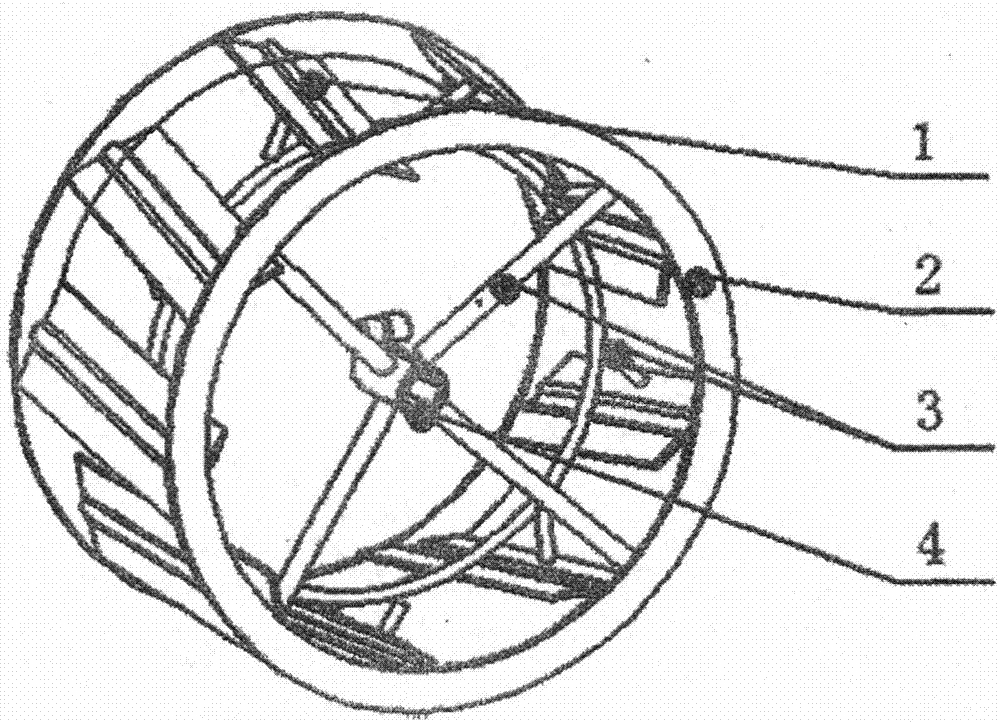

Primary feeding and crushing shaft for straw crushing machine

PendingCN108124614AUniform feedingIncrease feed rateCuttersAgriculture gas emission reductionEngineeringMechanical engineering

The invention discloses a primary feeding and crushing shaft for a straw crushing machine. The invention relates to a straw crushing machine to solve the problems that the primary feeding and crushingshaft on the existing straw crushing machine utilizes cutters to finish cutting and poking actions so as to cause slow feeding and cutting speed and further influence the straw crushing effect. The primary feeding and crushing shaft comprises a main shaft (1), an input belt wheel (2), two bearing seats (3), three cutter disc shafts (4), six pokers (7), a plurality of discs (5) and a plurality ofcutters (6), wherein the two ends of the main shaft (1) are supported in the bearing seats (3); the input belt wheel (2) is fixedly arranged on the input end of the main shaft (1); the plurality of discs (5) are positioned between the two bearing seats (3) and are fixedly arranged on the main shaft (1); the three cutter disc shafts (4) are uniformly arranged along the same circumference of the discs (5); each cutter disc shaft (4) penetrates through the plurality of discs (5) and is fixedly arranged on the plurality of discs (5); the gap position between every two adjacent discs (5) on each cutter disc shaft (4) is respectively provided with one cutter (6) or poker (7). The primary feeding and crushing shaft disclosed by the invention is used on the straw crushing machine.

Owner:哈尔滨重齿传动设备有限公司

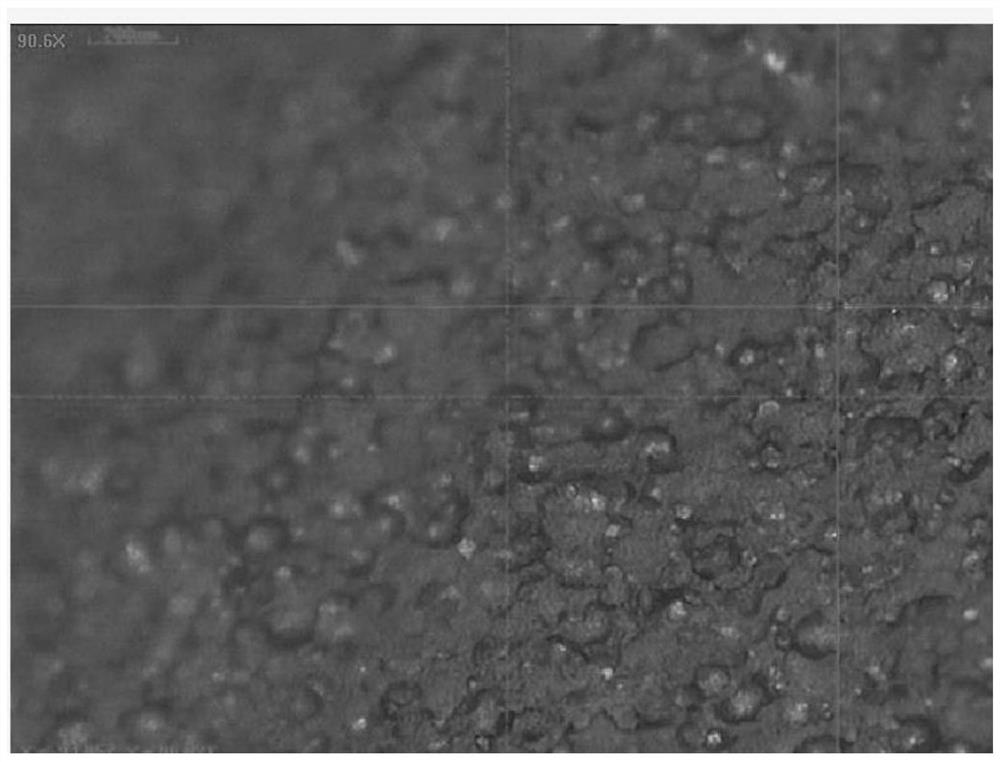

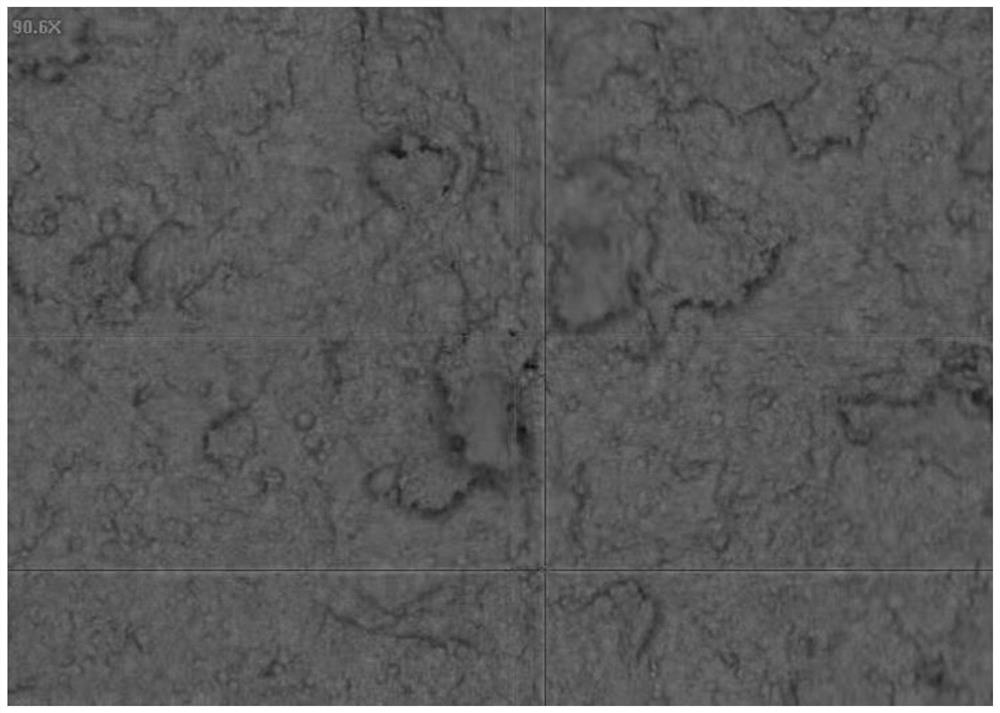

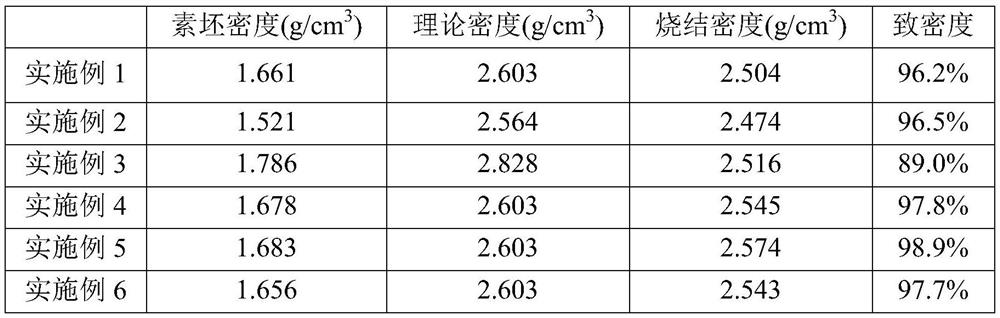

Preparation method of high-density boron carbide ceramic

ActiveCN114538929AHigh densitySolving the Densification ProblemNuclear energy generationSpray GranulationSlurry

The invention belongs to the technical field of ceramic materials, and particularly relates to a preparation method of high-density boron carbide ceramic, which comprises the following steps: S11, carrying out primary slurry preparation on boron carbide, and carrying out ball milling; s12, drying, crushing and sieving the ball-milled powder to obtain boron carbide modified powder; s21, carrying out secondary slurry preparation on the boron carbide modified powder and deionized water, adding a dispersing agent, and carrying out ball milling; s22, adding a sintering aid, a binder and a release agent, and continuing ball milling to obtain slurry; performing spray granulation: sieving the slurry, and performing spray granulation to obtain granulation powder; aging the granulated powder: adding ethanol into the granulated powder, uniformly stirring, adding into a sealed bag, and aging; dry-pressing the granulated powder: uniformly mixing the coarse granulated powder and the fine granulated powder according to a certain proportion, and pressing the mixed powder by using a dry press to obtain a biscuit; and high-temperature sintering: carrying out one-time debonding and sintering on the biscuit to obtain the boron carbide ceramic.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Preparation method of Cu-Al2O3 dispersion strengthened Cu-based composite coating

InactiveCN111349926AImprove scalabilityImprove the heating effectSolid state diffusion coatingHeat inorganic powder coatingSpray coatingInternal oxidation

The invention discloses a preparation method of a Cu-Al2O3 dispersion strengthened Cu-based composite coating. The preparation method specifically comprises the steps of conducting pretreatment on thesurface of a workpiece to be coated, selecting appropriate coating parameters according to the cold spraying process, and spraying Cu-Al alloy powder onto the surface of the pretreated workpiece to prepare a high-performance Cu-Al alloy coating; and finally, selecting appropriate internal oxidation treatment parameters through an internal oxidation method, promoting an Al phase in the Cu-Al alloycoating to have an in-situ reaction to generate an Al2O3 dispersed phase, and preparing the Cu-Al2O3 dispersion strengthened Cu-based composite coating. During the internal oxidation treatment process, the Al phase in the alloy coating has the in-situ reaction to generate the nanoscale Al2O3 dispersed phase, and the nanoscale Al2O3 dispersed phase is pinned inside deposited particles or at the interfaces of the deposited particles to hinder dislocation motion and improve the mechanical performance of the coating. Moreover, unbound interfaces between the as-sprayed coating particles are locally bound through diffusion in the internal oxidation treatment process, and the performance of the coating is further improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Treatment process of waste cells from amino acid fermentation

ActiveCN107011409BHigh purityHelp brokenFood processingAnimal feeding stuffBiotechnologyAmino acid fermentation

The invention belongs to the technical field of amino acid production and discloses a treatment process for amino acid fermentation waste cells, which includes the following steps: step 1) drying and crushing, step 2) salt treatment, ultrasonic treatment, step 3) hydrolysis, and step 4) adsorption , centrifugation, step 5) filtration, step 6) evaporation and drying, step 7) preparation of feed. This busy treatment process can prepare high-purity peptide products and feed products, avoiding the waste of bacterial raw materials.

Owner:内蒙古阜丰生物科技有限公司

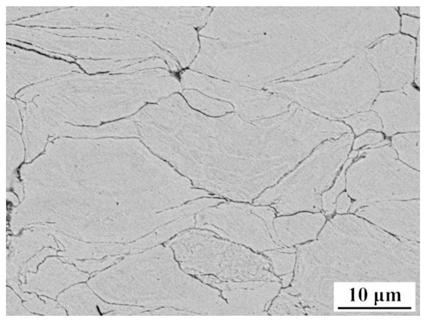

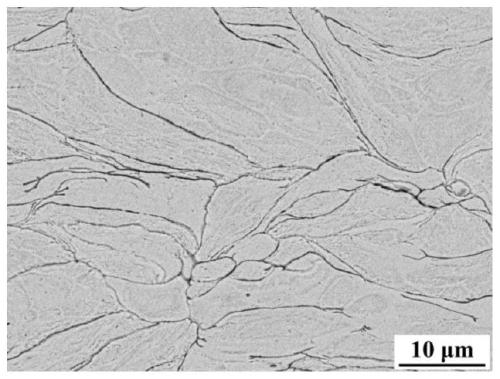

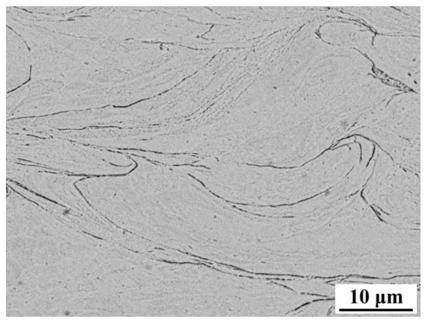

A kind of titanium-steel dissimilar metal structure and its preparation method

ActiveCN108817647BHigh strengthHigh tensile strengthWorkpiece edge portionsNon-electric welding apparatusEngineeringComposite plate

The invention provides a titanium-steel dissimilar metal structure and a preparation method thereof. The present invention obtains a sawtooth structure with a high degree of fit corresponding to the meshing by stacking and overlapping, and then obtains a composite plate through the meshing connection, and then realizes high-quality welding of titanium-steel dissimilar metals through the friction stir welding method, without considering the offset The impact on the performance of dissimilar metal friction stir welding joints eliminates the asymmetry of the advancing edge and the retreating edge in the traditional butt joint process; and the use of a sawtooth meshing structure increases the effect of the welding force on the material during the welding process on the one hand, which contributes to On the other hand, the linear contact area of dissimilar metals is increased, and the relative movement distance of metal atoms is reduced, so that more atoms can move under the same energy, and the mutual flow and mixing of dissimilar metal materials can be improved. The ability to avoid the problem of uneven mixing of the joint structure makes the weld material interlocking and mixing enhanced, thereby greatly improving the strength of the joint.

Owner:NANCHANG HANGKONG UNIVERSITY

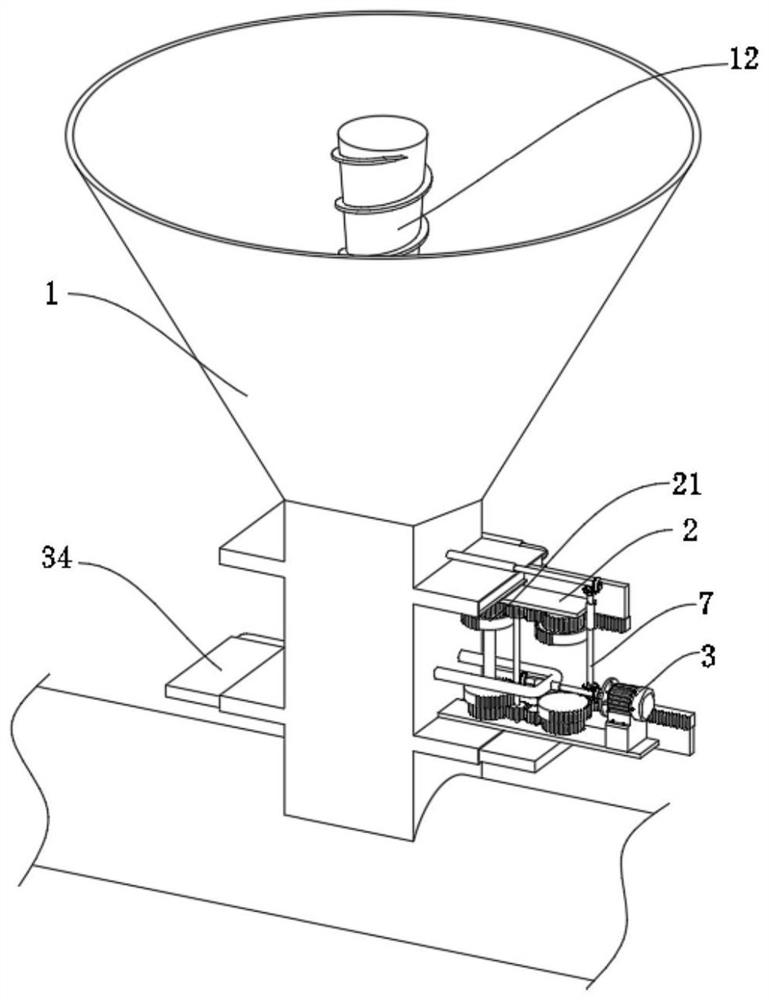

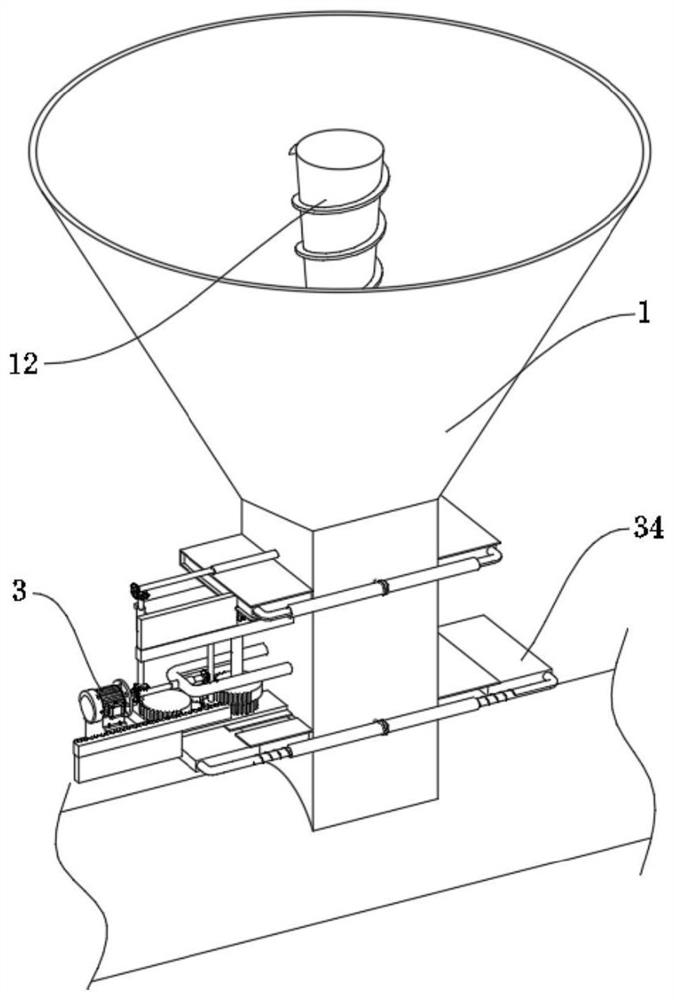

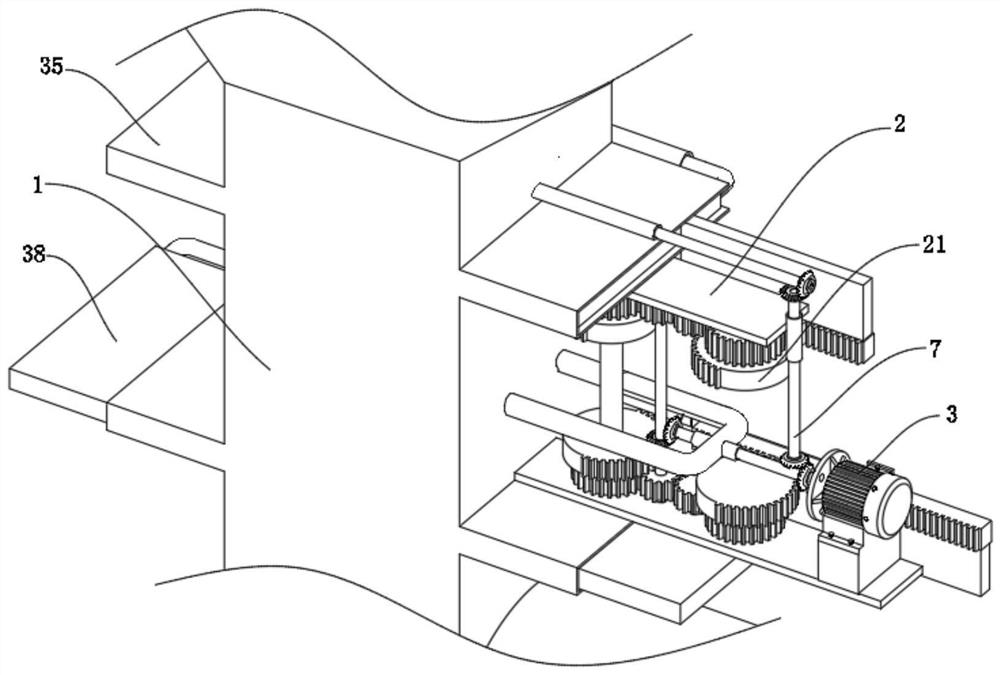

Grinding device for ceramic processing production

The present invention belongs to the technical field of ceramics processing, in particular to a grinding device for processing and producing ceramics; the grinding device comprises a frame body; crushing plates are uniformly arranged on an inner wall of the frame body; the crushing plates are fixedly connected into the inner wall of the frame body through first springs; a rubber filter plate is arranged in the frame body; a rolling block is rotatably connected to the inner wall of the frame body through a rotating shaft; grinding grooves are arranged in the filter plate; second grinding ballsare unevenly arranged in the grinding grooves; a liquid nitrogen tank is arranged at a top of the frame body; and liquid nitrogen guns are evenly arranged on a side wall of a feeding inlet. The grinding device of the present invention has the characteristics that the ceramics are bounced to be initially crushed through the elasticity of the filter plate after being frozen instantaneously, the ceramics are filtrated through the second grinding balls in the filter plate after being secondly ground, and the ceramics are thirdly ground through the rolling block, so that the ceramics are crushed completely without crushed dead corners; besides, the device has long service life and is easy to operate.

Owner:湖南鑫斯科技有限公司

A nanometer metal cleaning device with integrated functions of crushing and stirring

ActiveCN103934070BEfficient crushingImprove cleaning efficiencyCleaning using liquidsEngineeringSewage

The invention discloses a nano metal cleaning device with a crushing and stirring integrated function. The nano metal cleaning device comprises a motor, an end cover, a cleaning agent inlet, a barrel body, a material outlet, a rotating shaft, a helical ribbon stirrer, a scraper, a sewage drainage opening, a conical end socket and a material inlet, wherein the end cover is arranged on the top of the barrel body; the conical end socket is arranged at the bottom of the barrel body; the material outlet and the sewage drainage opening are formed in the bottom of the conical end socket; the cleaning agent inlet and the material inlet are formed in the side wall of the upper end of the barrel body; the motor is arranged at the top end of the end cover; the torque output end of the motor is connected with the rotating shaft extending into the barrel body; the helical ribbon stirrer and the scraper are arranged on the rotating shaft from top to bottom in sequence; a distance between the scraper and the inner wall of the barrel body and a distance between the scraper and the inner wall of the conical end socket are 5-8mm, respectively. The nano metal cleaning device can be widely applied to cleaning of high-viscosity solids, particularly floccular or mud-block-shaped solids with the certain content of moisture (80 percent).

Owner:XI AN JIAOTONG UNIV

A homogeneous high-strength and toughening magnesium alloy cup-shaped member rotary extrusion method

The invention discloses a rotary extrusion method of a homogenous high-toughness magnesium alloy cup-shaped component. The rotary extrusion method of the homogenous high-toughness magnesium alloy cup-shaped component comprises the following steps: (1) blanking a bar material; (2) carrying out homogenizing thermal treatment; (3) heating the whole rotary extrusion mold, wherein the rotary extrusion mold mainly comprises a punch and a forming concave mold for the rotary extrusion cup-shaped component, the punch is connected with an upper rotary workbench of a hydraulic machine with the upper rotary workbench, the surface of a conical body of the end part of the punch in contact with an extrusion billet is provided with non-communicated grooves with certain widths and depths, and a groove is formed in the plane of the bottom of a mold cavity of the forming concave mold; spraying oiling agent graphitic lubricant for a punch operating belt, the non-communicated grooves, the mold cavity and the blank; installing the blank for extrusion into the mold cavity; (4) moving the upper rotary workbench of the hydraulic machine around a rotary axis, loading the blank around the rotary axis, and filling metal extruded into the non-communicated grooves by the punch when the punch moves around the rotary axis continuously in a smoothing-raising-smoothing-raising mode; (5) processing an extrusion element so as to form the magnesium alloy cup-shaped component.

Owner:ZHONGBEI UNIV

A process for effectively utilizing glutamic acid to ferment waste bacterial protein

ActiveCN107418897BHigh purityHelp brokenMicroorganism lysisMicroorganism based processesMicroorganismMycoprotein

The invention relates to the technical field of microbiology, and discloses a process for effectively utilizing discarded mycoprotein in a glutamic acid fermentation broth. The process comprises the steps of (1) centrifugation, stoving and smashing; (2) cell wall breaking, hydrolysis and centrifugation; and (3) adsorption, microfiltration, ultrafiltration and drying. Enzyme treatment is not adopted to save cost, peptide products with high purity are prepared, and the industrial added value is high.

Owner:内蒙古阜丰生物科技有限公司

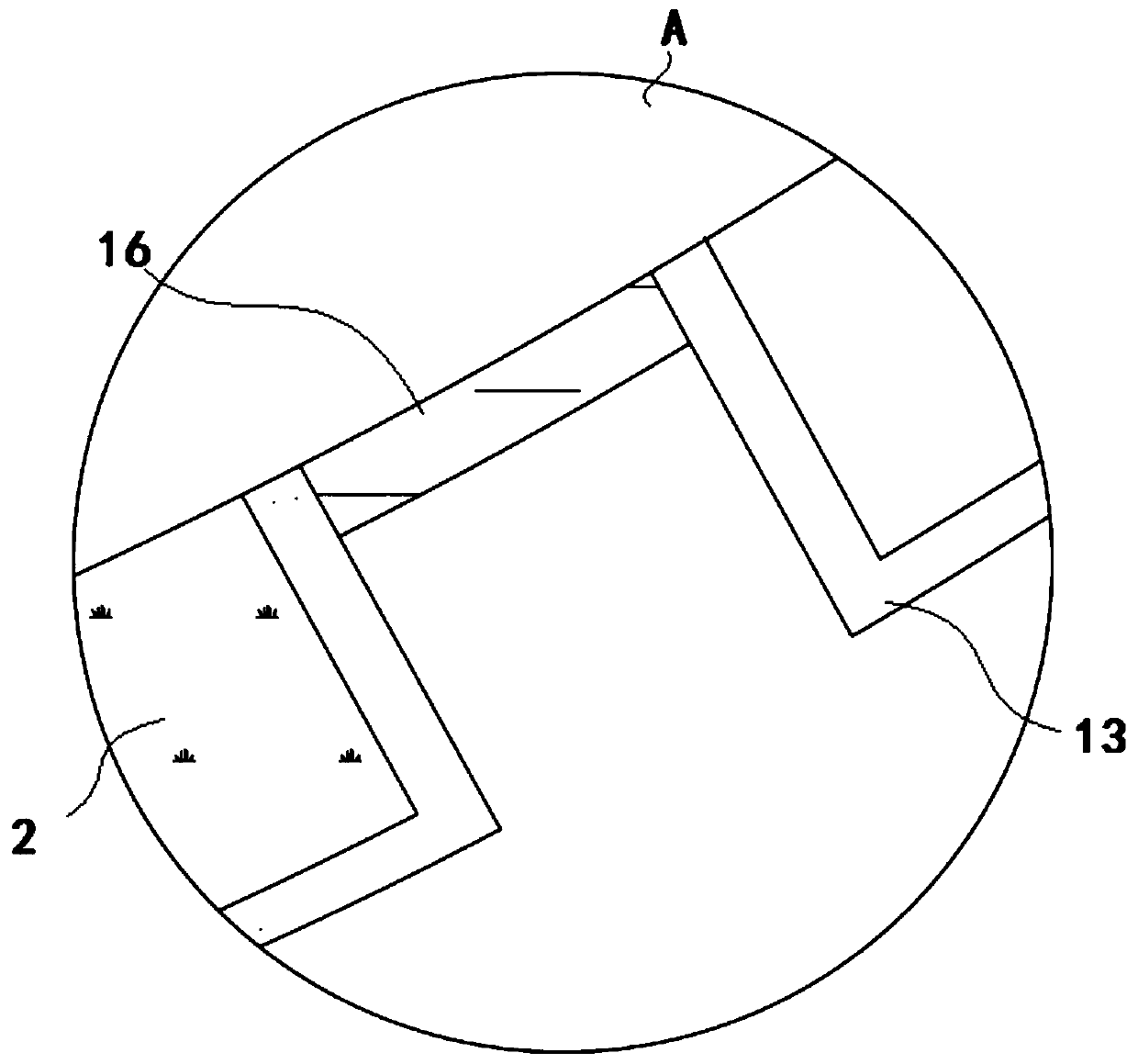

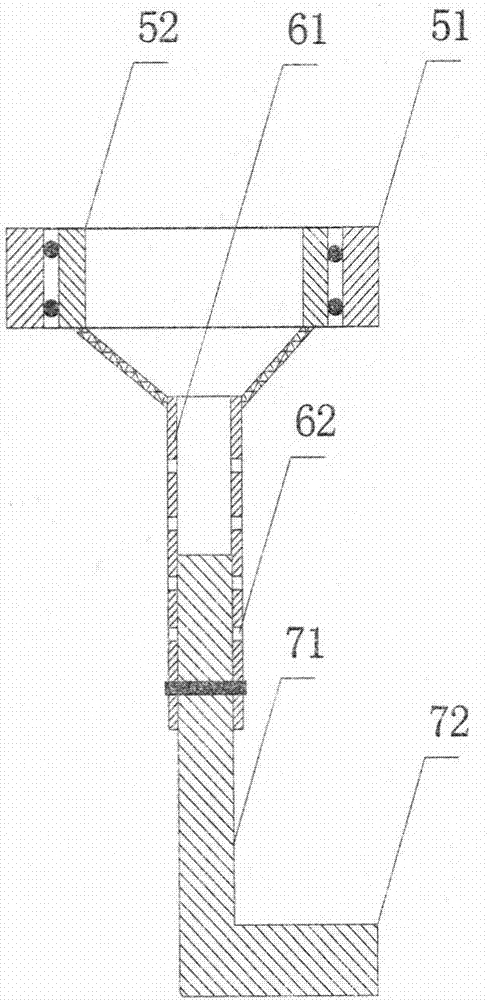

Front Tiller with Depth Limiting Function

InactiveCN104904338BAdjustable distanceAdjust the depth of rotary tillageTilling equipmentsPulp and paper industryDepth limit

The invention provides a front-set micro-tillage machine with a depth-limiting function. The micro-tillage machine comprises a machine wheel and a rotary tillage device. The micro-tillage machine further comprises a fixation frame, a rotation mechanism, a supporting part and an adjustment unit, wherein the fixation frame and the rotary tillage device are installed on the same side of the machine wheel; the rotation mechanism is directly or indirectly installed on the fixation frame; the supporting part is installed on the rotation mechanism; and the adjustment unit is used to adjust a relative distance between the supporting part and the fixation frame. The front-set micro-tillage machine with the depth-limiting function provided by the invention has the advantages such as conveniently operations, a simple structure, convenient processing, and low cost, etc.

Owner:安徽鲁班集团神牛机械有限公司

Sludge carbonization device for environmental protection equipment

PendingCN113698059AEasy accessEasy to weigh quantitativelyRotary stirring mixersSludge treatment by pyrolysisSludgeElectric machine

The invention discloses a sludge carbonization device for environmental protection equipment. The sludge carbonization device comprises a feeding cylinder; two fixing plates, which are distributed in a symmetrical structure and are fixedly connected with the feeding cylinder, wherein plugging assemblies are arranged on the outer sides of the fixing plates; a motor, wherein an output shaft of the motor is fixedly connected with a third rotating rod, one end of the third rotating rod is fixedly connected with a sixth bevel gear, the other end of the third rotating rod is fixedly connected with a seventh bevel gear, and one side of the seventh bevel gear is provided with an adjusting assembly used for adjusting opening and closing of the plugging assemblies; and a linkage assembly, which is used for being connected between the plugging assemblies and the adjusting assembly. Through rotation of the motor, closing and opening of an upper movable plate and closing and opening of a lower movable plate are matched with each other, and drum rotating, sludge blocking quantification and sludge opening after quantification are completed.

Owner:胡太为

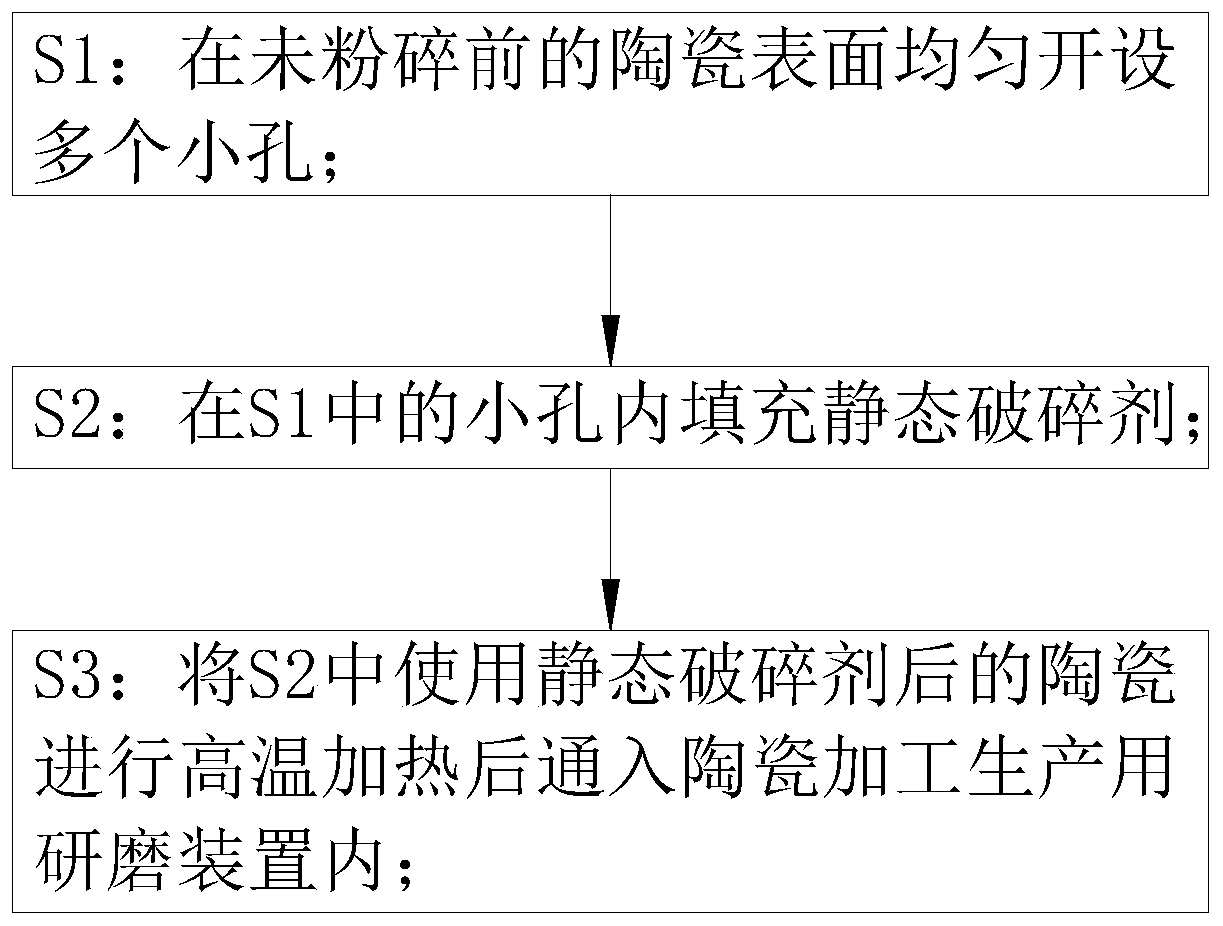

A grinding process for ceramic processing production

ActiveCN109351427BConvenient post-crushingEasy to grind and crushGrain treatmentsRubber materialCeramic

Owner:肇庆市璟盛陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com