Hydraulically-driven multi-dimensional plasma combined drill bit and well drilling method thereof

A hydraulic drive, plasma technology, applied to drill bits, drilling equipment, application of thermal energy drilling, etc., can solve the problem of increased drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

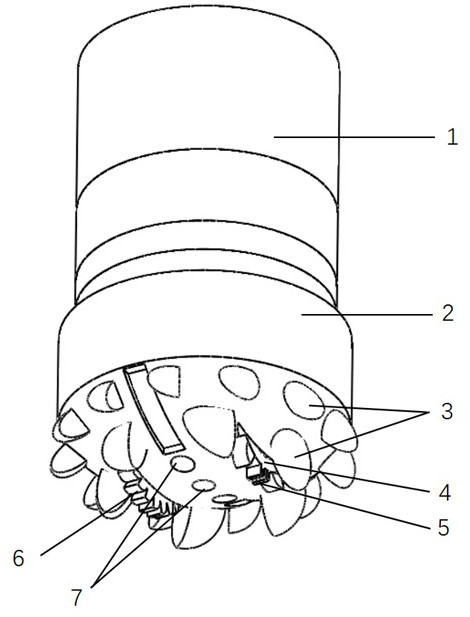

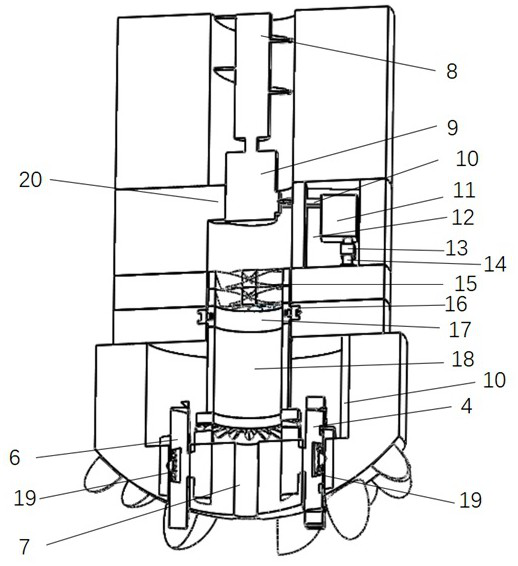

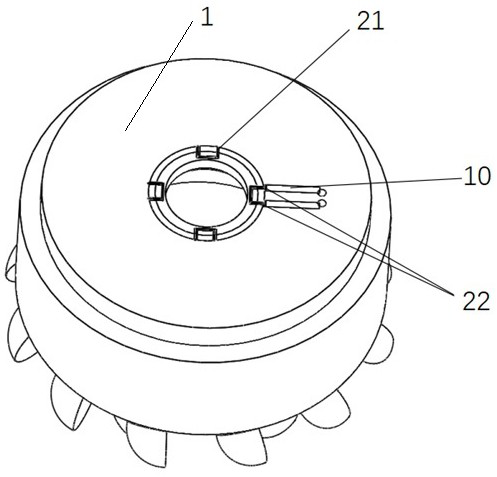

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

[0031] This hydraulically driven multi-dimensional plasma combined drill bit includes drill pipe 1, drill bit 2, cutting teeth 3, plasma turntable gear 4, multiple plasma devices 5, mechanical cutting gear 6, mud turbine 8, generator 9, drill pipe 1 A mud turbine 8 is arranged inside, and the bottom of the mud turbine 8 is connected to the generator 9. The energy storage compartment 12 is arranged on the lower right side of the generator 9. The generator 9 is connected to the cable 10, and the cable 10 extends into the energy storage compartment 12 for energy storage. A rechargeable battery 11, an energy storage capacitor 13, and a freewheeling diode 14 are installed inside the cabin 12, and two pairs of cables extend downward from the bottom of the energy storage cabin 12; The generator 9, the turbine blades 15, the turntable switch 17, the upper gear 18, and the water ey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com