Preparation method of high-density boron carbide ceramic

A boron carbide ceramics, density technology, applied in the field of ceramic materials, can solve the problems of boron carbide ceramics difficult to sinter and compact, low self-diffusion coefficient, etc., to achieve the effect of promoting sintering densification, improving dispersion, and eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

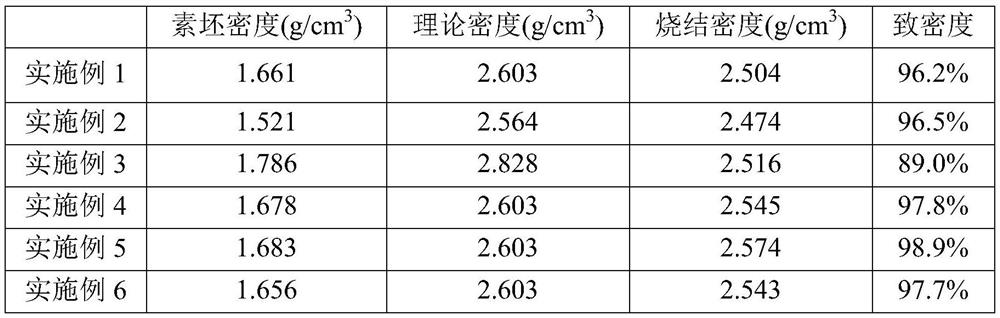

Embodiment 1

[0051] Boron carbide primary paste:

[0052] S11, the polyethyleneimine aqueous solution that is 50% by mass percent concentration and the boron carbide micropowder are carried out a slurry (polyethyleneimine molecular weight is 70000, and the consumption of polyethyleneimine accounts for 1.2% of the total mass of boron carbide micropowder), and then Use 10mm boron carbide balls for ball milling, the mass ratio of boron carbide balls to boron carbide micropowder is 2:1, the speed of ball milling is 30rpm, and the ball milling time is 4h;

[0053] S12. Dry the ball-milled slurry at 50° C. for 48 hours, then crush it with a pulverizer, and pass it through a 40-mesh sieve to obtain a boron carbide modified powder;

[0054] Boron carbide secondary paste:

[0055] S21. The boron carbide modified powder and deionized water are mixed for the second time according to the solid content of 55%, and a dispersant accounting for 0.8% of the total mass of the boron carbide modified powder ...

Embodiment 2

[0062] Boron carbide primary paste:

[0063] S11, the polyethyleneimine aqueous solution that is 50% by mass percent concentration and the boron carbide micropowder are carried out a slurry (polyethyleneimine molecular weight is 80000, and the consumption of polyethyleneimine accounts for 0.5% of the total mass of boron carbide micropowder), and then Use 8mm finely ground boron carbide balls for ball milling, the mass ratio of boron carbide balls to boron carbide micropowder is 1:1, the speed of ball milling is 20rpm, and the ball milling time is 5h;

[0064] S12. Dry the ball-milled slurry at 45°C for 50 hours, then crush it with a pulverizer, and pass it through a 40-mesh sieve to obtain a boron carbide modified powder;

[0065] Boron carbide secondary paste:

[0066] S21. The boron carbide modified powder and deionized water are mixed according to the solid content of 50% for the second time, and a dispersant accounting for 1% of the total mass of the boron carbide modifie...

Embodiment 3

[0073] Boron carbide primary paste:

[0074] S11, the polyethyleneimine aqueous solution that is 50% by mass percent concentration and the boron carbide micropowder are carried out one time slurrying (polyethyleneimine molecular weight is 60000, and the consumption of polyethyleneimine accounts for 2% of the total mass of boron carbide micropowder), then Use 12mm finely ground boron carbide balls for ball milling, the mass ratio of boron carbide balls to boron carbide micropowder is 3:1, the speed of ball milling is 40rpm, and the ball milling time is 3h;

[0075] S12. Dry the ball-milled slurry at 55° C. for 45 hours, then crush it with a pulverizer, and pass it through a 40-mesh sieve to obtain a boron carbide modified powder;

[0076] Boron carbide secondary paste:

[0077] S21. The boron carbide modified powder and deionized water are mixed according to the solid content of 60% for the second time, and a dispersant accounting for 0.8% of the total mass of the boron carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com