Method for promoting anaerobic digestion of excess sludge through pretreatment of ultrasonic waves and hydrogen peroxide

A technology of hydrogen peroxide and excess sludge, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve problems such as high energy consumption, complicated operation, and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

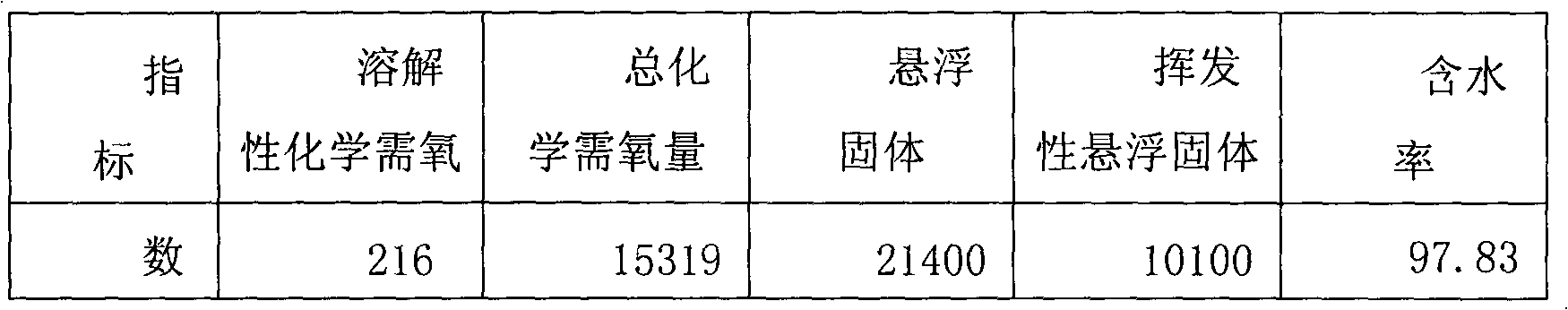

[0020] The properties of the remaining sludge of a city sewage treatment plant in a certain place after gravity concentration are shown in the table below.

[0021]

[0022] Add hydrogen peroxide to the sludge so that the ratio of the amount of hydrogen peroxide to the total suspended solids of the sludge is 4.67mg / gTSS. After stirring rapidly for 3 minutes, it is sent to an ultrasonic reactor for ultrasonic irradiation. The ultrasonic frequency is 20KHz. The sound energy density is 1W / mL, and the irradiation time is 90min. After that, take 500mL combined pretreatment mud sample and send it to an anaerobic digestion reactor with a feeding ratio of 50%. Place it in a constant temperature room at 35±2°C for mesophilic anaerobic digestion, and use a magnetic stirrer for mixing. The dissolved chemical oxygen demand in the treated sludge increased to 5366.08mg / L, which was 23.83 times higher than that of the untreated sludge. After 12 days of anaerobic digestion of pretreated s...

Embodiment 2

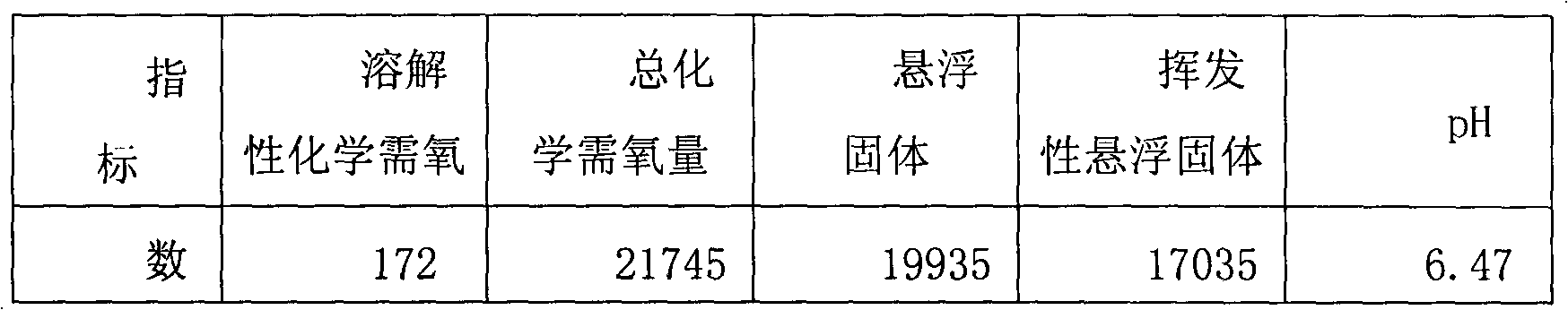

[0024] The properties of the remaining sludge of a city sewage treatment plant after gravity concentration are shown in the table below.

[0025]

[0026] Add hydrogen peroxide to the sludge so that the ratio of the amount of hydrogen peroxide to the total suspended solids of the sludge is 15.05mg / gTSS. After stirring rapidly for 3 minutes, it is sent to an ultrasonic reactor for ultrasonic irradiation. The ultrasonic frequency is 20KHz. The sound energy density is 1W / mL, and the irradiation time is 60min. After that, take 500mL combined pretreatment mud sample and send it to an anaerobic digestion reactor with a feeding ratio of 50%. Place it in a constant temperature room at 35±2°C for mesophilic anaerobic digestion, and use a magnetic stirrer for mixing. The dissolved chemical oxygen demand in the treated sludge increased to 7247.20mg / L, which was 41.18 times higher than that of the untreated sludge. After 18 days of anaerobic digestion, the biogas production increased ...

Embodiment 3

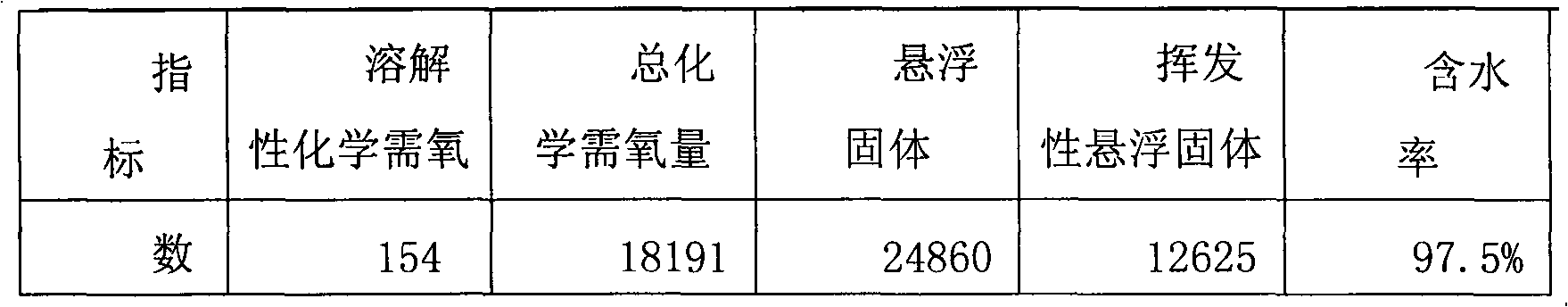

[0028] The properties of the remaining sludge of a city sewage treatment plant in a certain place after gravity concentration are shown in the table below.

[0029]

[0030] Add hydrogen peroxide to the sludge so that the ratio of the amount of hydrogen peroxide to the total suspended solids of the sludge is 20.11mg / gTSS. After stirring rapidly for 10 minutes, it is sent to an ultrasonic reactor for ultrasonic irradiation. The ultrasonic frequency is 20KHz. The sound energy density is 1W / mL, and the irradiation time is 60min. After that, take 500mL combined pretreatment mud sample and send it to an anaerobic digestion reactor with a feeding ratio of 50%. Place it in a constant temperature room at 35±2°C for mesophilic anaerobic digestion, and use a magnetic stirrer for mixing. The dissolved chemical oxygen demand in the treated sludge increased to 4438.65mg / L, which was 27.84 times higher than that of the untreated sludge. After 12 days of anaerobic digestion of pretreated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com