Process for producing fuel oil by thermal cracking of biomass

A biomass thermal cracking and fuel oil technology, which is used in the petroleum industry, the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, etc. The effect of investment and cumbersome production process, avoiding secondary pollution and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

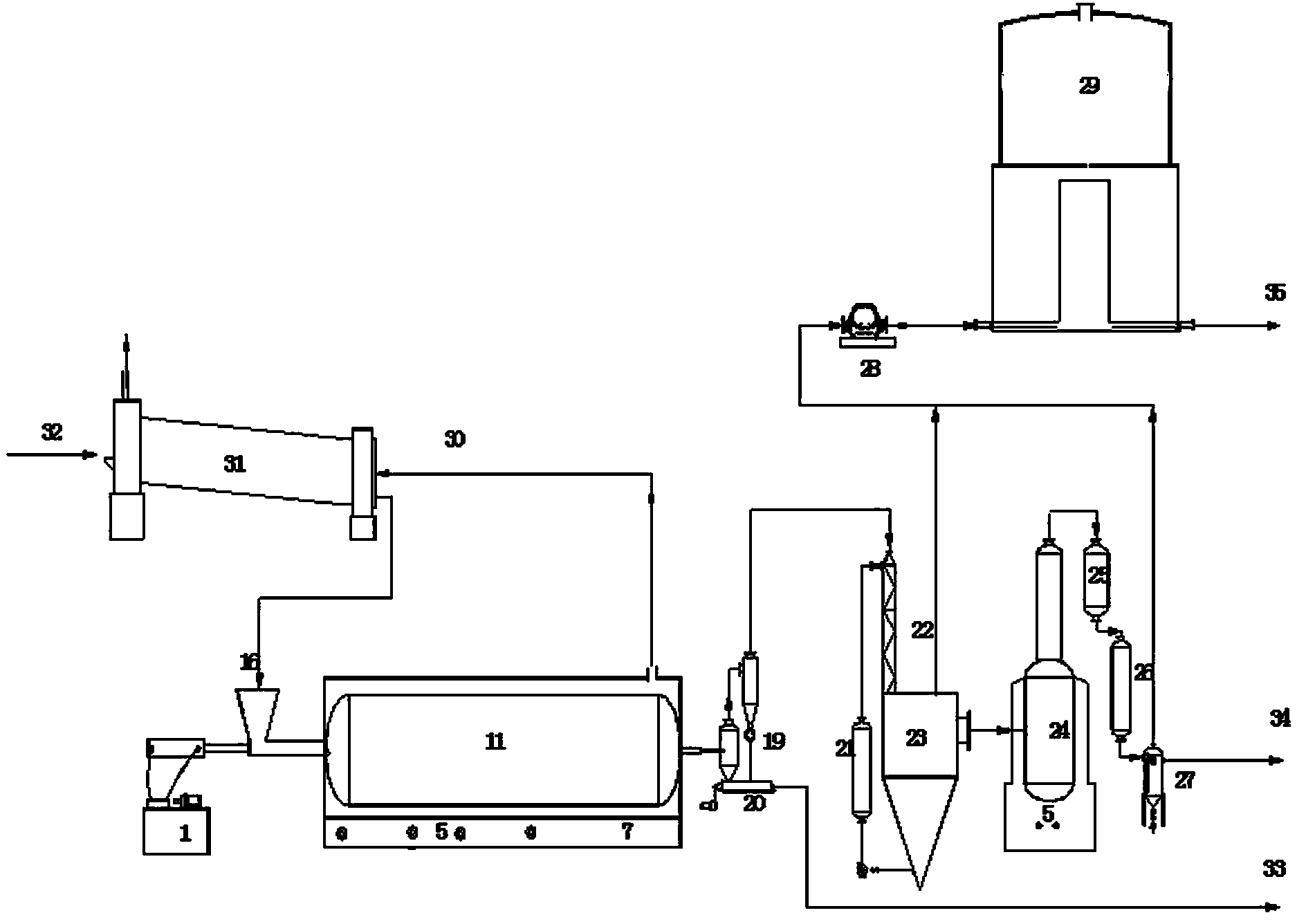

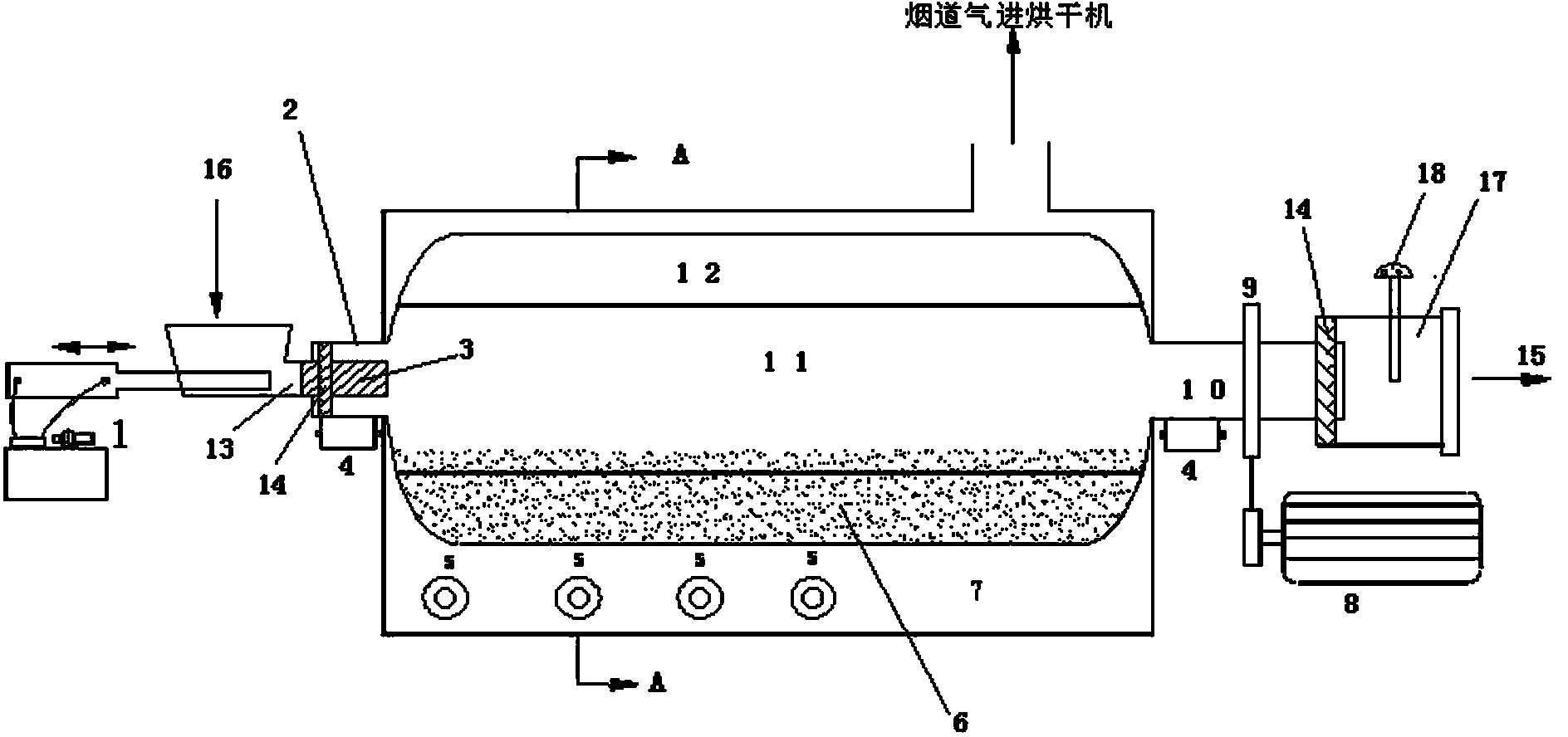

[0036] see figure 1 , the technology of biomass thermal cracking to produce fuel oil is characterized in that it comprises the following steps:

[0037] a. Raw material preparation: the raw material is biomass, which has been dried; the biomass raw material is cotton stalks and branches, sawdust, shavings, wheat straw, waste plastics, straw, and rice husk;

[0038] Or the raw material is biomass and waste plastics, the weight mixing ratio of biomass and waste plastics is: 7 parts of biomass, ≥ 2 parts of waste plastics (such as 2, 3, 5, 7, etc., no matter how much, only waste plastics Available); the effect can meet the requirements.

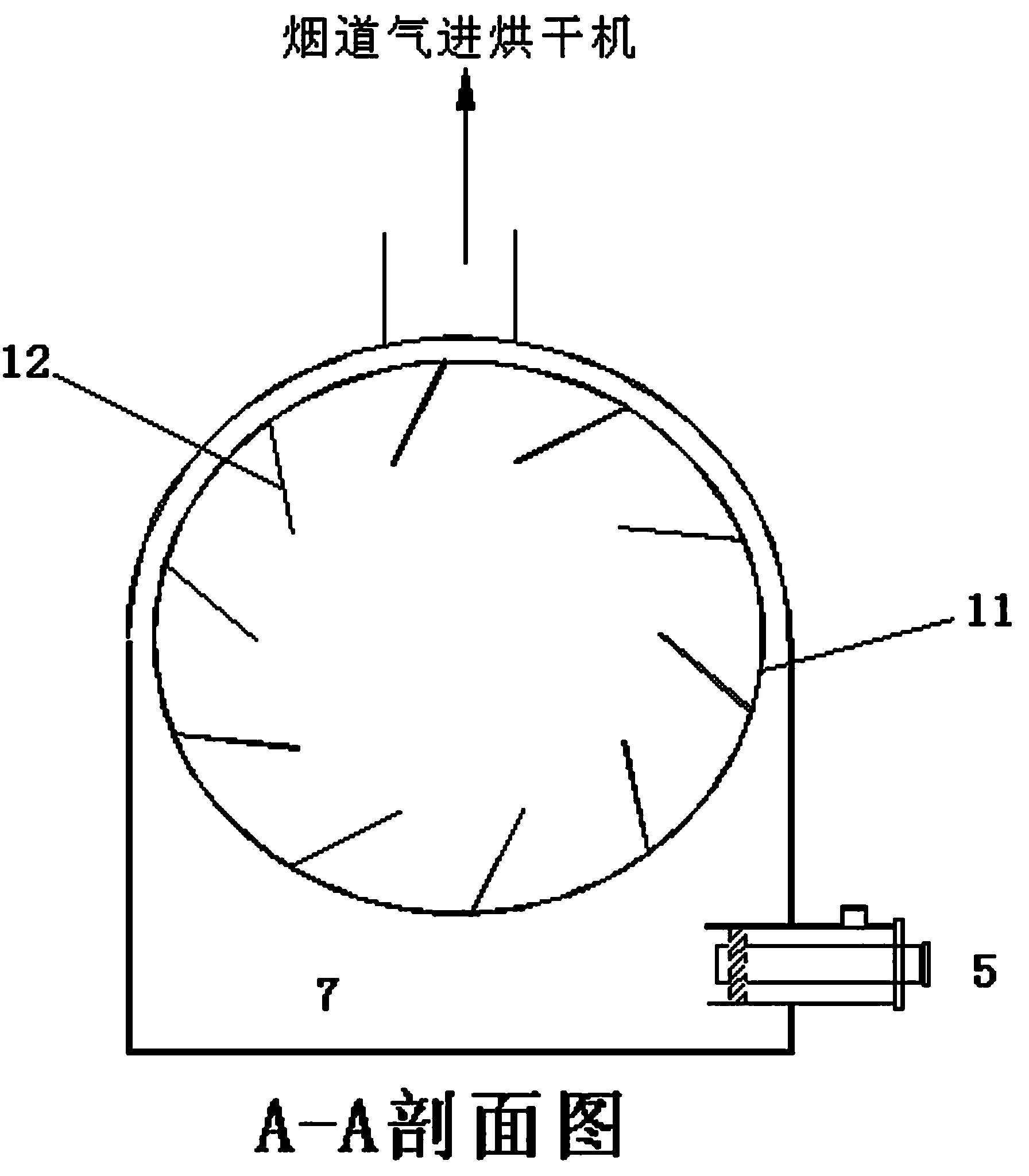

[0039] b. The raw material is thermally coupled with the heat carrier in the rotary cracking furnace with built-in heat carrier and undergoes thermal cracking reaction: ash and oil gas are generated;

[0040] c. Gas-solid separation of ash and oil and gas generated after the reaction: the ash is discharged, and the oil and gas are condensed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com