Preparation method of Cu-Al2O3 dispersion strengthened Cu-based composite coating

A technology for dispersion-strengthened copper and Al2O3, applied in coating, solid-state diffusion coating, metal material coating process, etc., can solve the limitation of application of dispersion-strengthened copper-based composite materials, complex preparation process, and single sample shape and other problems, to achieve the effect of promoting fresh metal contact, improving interfacial bonding, and improving coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A method for preparing a copper-aluminum oxide dispersion-strengthened copper-based composite coating of the present invention is specifically implemented according to the following steps:

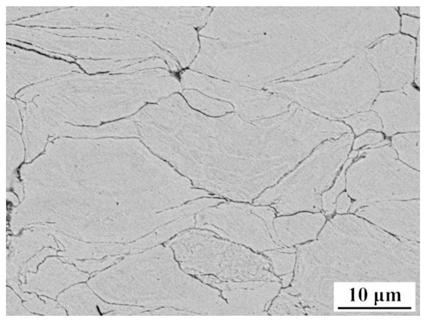

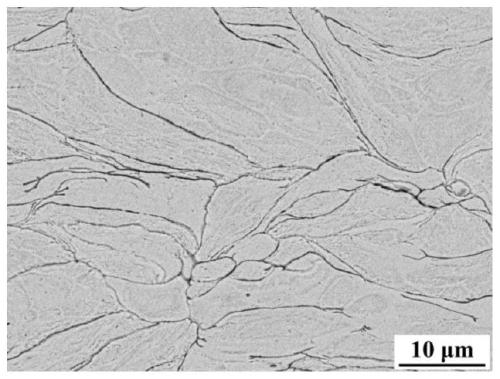

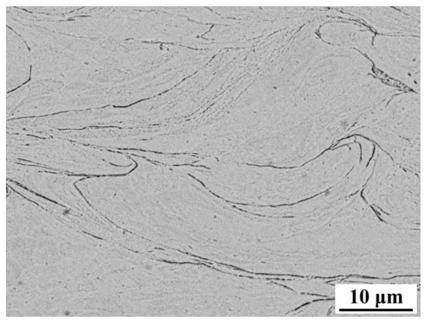

[0034]For the Cu-Al alloy system powder, the nearly spherical Cu-Al alloy powder is used as the spray powder, and the PCS-1000 cold spray system developed by Plasma Giken is used in the preparation process of the Cu-Al alloy coating. The system uses a Laval nozzle with a throat diameter of 2 mm, an outlet diameter of 4.4 mm, and a downstream length of 170 mm. Use N during spraying 2 As powder feeding gas and accelerating gas. Cu-Al alloy coatings were prepared by adjusting the parameters of the spraying process so that the powder particles were deposited at different speeds. The DPV-2000 (Tecnar Automation LY., St-Bruno, Qc, Canada) test system was used to characterize the velocity of the particles before they hit the substrate under the corresponding spraying parameters. The resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com