Oxygen lance slag scraper

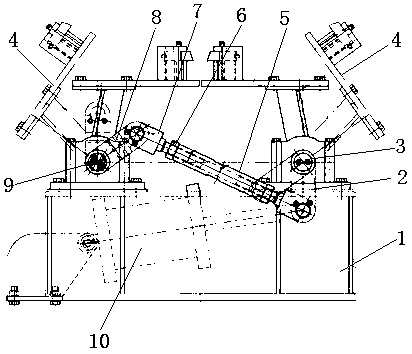

A technology of slag scraper and oxygen lance, which is applied in the direction of manufacturing converters and improving process efficiency, etc. It can solve the problems of poor slag scraping effect, short service life, and potential safety hazards, so as to achieve improved slag scraping effect and service life , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

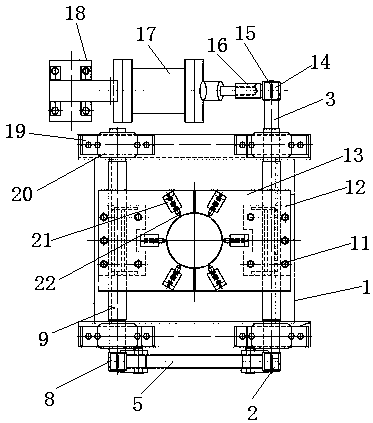

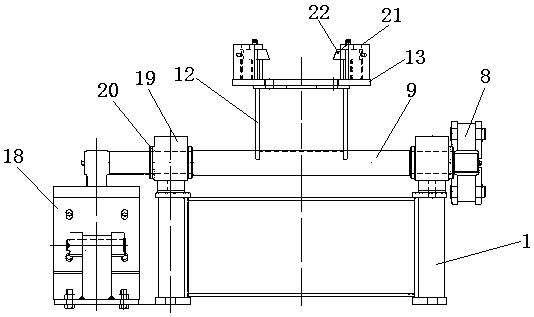

Embodiment approach

[0028] One embodiment, the drive mechanism 10 includes a cylinder base 18, a cylinder 17 and a fork 16, the cylinder 17 is fixed on the cylinder base 18 through its tail lug seat, and the movable end of the cylinder 17 is connected to one end of the fork 16, The other end of the fork 16 is hinged with the connecting rod-14; when the oxygen lance is scraped, the cylinder 17 controls the piston rod of the cylinder to stretch out, and the fork 16 at the movable end of the piston rod drives the connecting rod-14 to move, thereby pushing the driving shaft 3 rotations; and after finishing the slag scraping, the cylinder 17 controls the piston rod to retreat, and the fork 16 at the movable end of the piston rod drives the connecting rod 14 to move in the opposite direction, thereby promoting the driving shaft 3 to rotate in the opposite direction. The connecting rod assembly includes two connecting rod yokes 7, a pull rod 5 and a nut 6, one end of the two connecting rod yokes 7 is thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com