Method for utilizing enhanced pretreatment to promote anaerobic digestion of excess sludge

A technology of excess sludge and anaerobic digestion, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of high energy consumption, poor wall breaking effect of excess sludge, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] After the residual sludge of an urban sewage treatment plant is settled by gravity, the moisture content of the sludge is 97.51%. Sodium hypochlorite solution with an available chlorine content of 3.58% is added to the sludge to make the available chlorine content in the sludge 2.01mg / gTSS, and the sludge is quickly Stir for 30s, then use 20kHz, 1W / mL ultrasonic treatment for 1h, take 500mL combined pretreated sludge sample and anaerobic inoculated sludge at a ratio of 1:1 and send it to the anaerobic digestion reactor. The organic matter load was 159.36mgSCOD / gVSS, and it was placed in a constant temperature room at 35±2°C for mesophilic anaerobic digestion. During the anaerobic digestion process, a magnetic stirrer was used to stir the sludge. After pretreatment, the dissolved chemical oxygen demand in the sludge liquid phase can reach 4358.71mg / L, which is about 27.32 times higher than that of untreated sludge. After 13 days of anaerobic digestion of sludge pretreate...

Embodiment 2

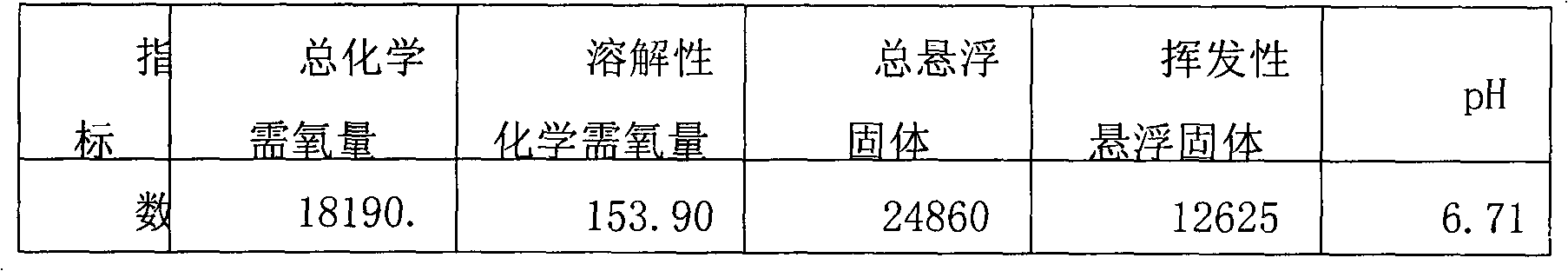

[0021] The properties of the remaining sludge in a sewage treatment plant after gravity settlement are shown in the table below.

[0022]

[0023] Add sodium hypochlorite solution with an available chlorine content of 3.58% to the sludge, so that the available chlorine content in the sludge is 4.02mg / gTSS, stir and mix for 30s, and then use 20kHz, 1W / mL ultrasonic treatment for 1h, take 500mL after joint pretreatment The sludge sample and anaerobic inoculated sludge were sent to the anaerobic digestion reactor at a ratio of 1:1. The initial organic matter load in the anaerobic reactor was 177.88mg / gVSS, and placed in a constant temperature room at 35±2°C for mesophilic anaerobic digestion. Digestion, a magnetic stirrer is used to stir the sludge during anaerobic digestion. After pretreatment, the dissolved chemical oxygen demand in the sludge liquid phase can reach 4408.67mg / L, which is about 27.65 times higher than that of untreated sludge. After 13 days of anaerobic dige...

Embodiment 3

[0025] The residual sludge of an urban sewage treatment plant has a water content of 97.53% through gravity sedimentation, and sodium hypochlorite solution with an effective content of 3.58% is added to the sludge to make the available chlorine content in the sludge 8.04mg / gTSS, and the sludge is stirred rapidly for 10 minutes , followed by 20kHz, 1W / mL ultrasonic treatment for 1h, and 500mL of combined pretreated sludge sample and anaerobic inoculation sludge were sent to the anaerobic digestion reactor at a ratio of 1:1, and the initial organic matter load in the reactor was 152.94 mgSCOD / gVSS, placed in a constant temperature room at 35±2°C for mesophilic anaerobic digestion, using a magnetic stirrer to stir the sludge during anaerobic digestion. After pretreatment, the dissolved chemical oxygen demand in the sludge liquid phase can reach 4738.41mg / L, which is about 29.79 times higher than that of untreated sludge. After 13 days of anaerobic digestion of sludge pretreated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com