Grinding device for ceramic processing production

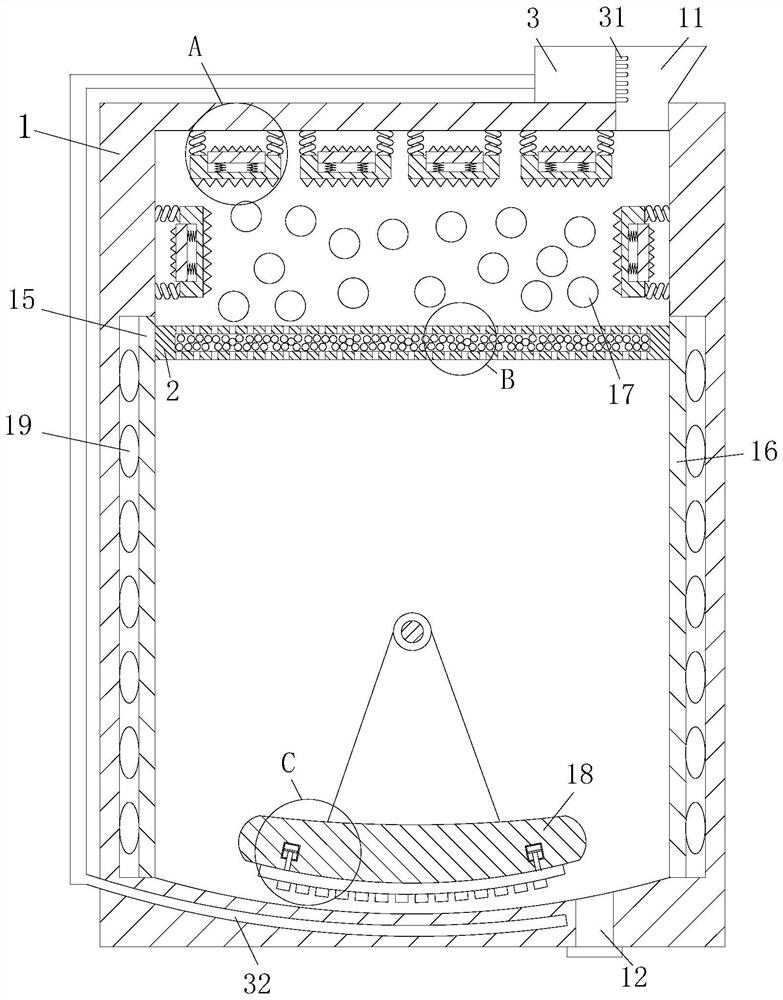

A grinding device and ceramic processing technology, which is applied in the field of ceramic processing, can solve the problems of inability to discharge a large amount of heat, incomplete screening process, and short service life of the device, so as to achieve full and thorough grinding, improve grinding efficiency, and accelerate filtration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

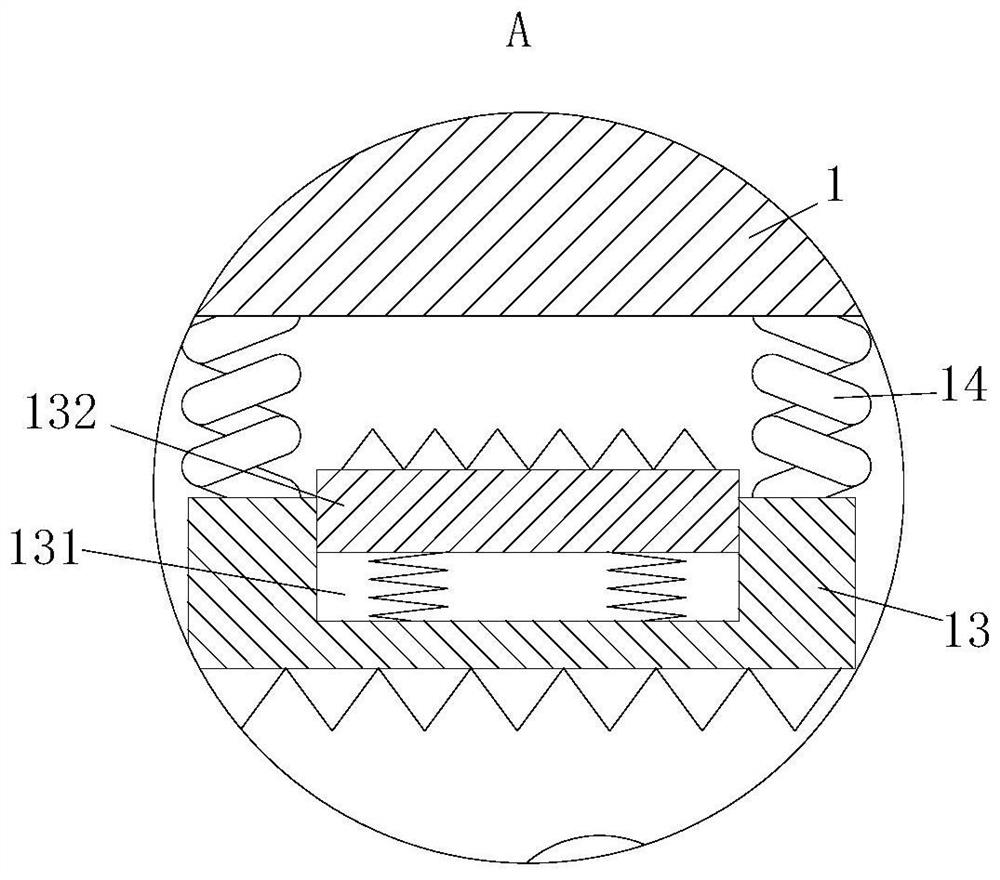

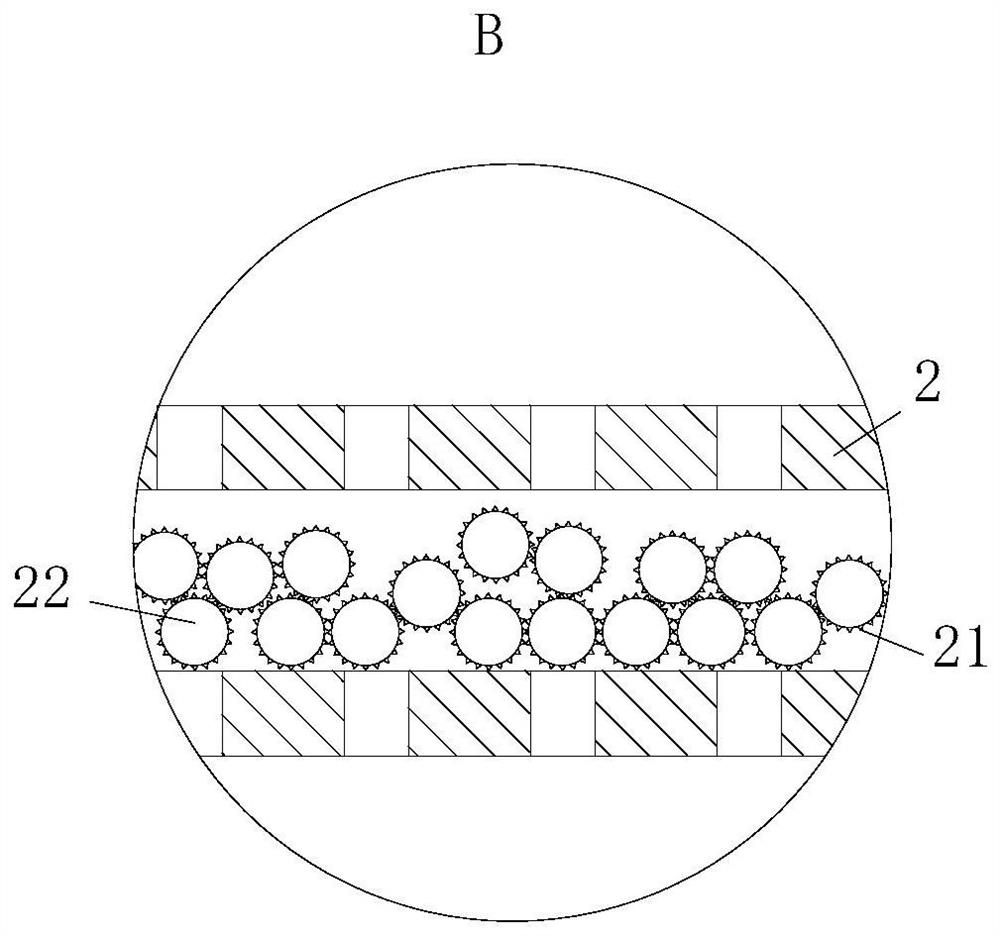

[0024] As an embodiment of the present invention, both the first pressing plate 15 and the second pressing plate 16 are fixedly connected to the inner wall of the frame body 1 through the air bag 19; when working, the rolling block 18 rotates, pressing and loosening in sequence The first squeeze plate 15, the filter plate 2 and the second squeeze plate 16, when the first squeeze plate 15 is squeezed, the first squeeze plate 15 pulls the filter plate 2, so that the filter plate 2 is in a straightened state and continues to rotate , loosen the first squeeze plate 15, squeeze the filter plate 2, make the filter plate 2 protrude instantly, bounce the ceramics and the first grinding ball 17, continue to rotate, loosen the filter plate 2, squeeze the second squeeze plate 16 , the second extrusion plate 16 straightens the curved filter plate 2 instantly, strengthens the downward movement speed of the filter plate 2, strengthens the bouncing strength of the ceramics and the first grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com