A kind of titanium-steel dissimilar metal structure and its preparation method

A dissimilar metal and titanium alloy technology, which is applied in the field of titanium-steel dissimilar metal structure and its preparation, can solve the problems of poor joint strength and poor material mixing degree, and achieve increased strength, increased tensile strength, and help for crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a titanium-steel dissimilar metal structure, comprising the following steps:

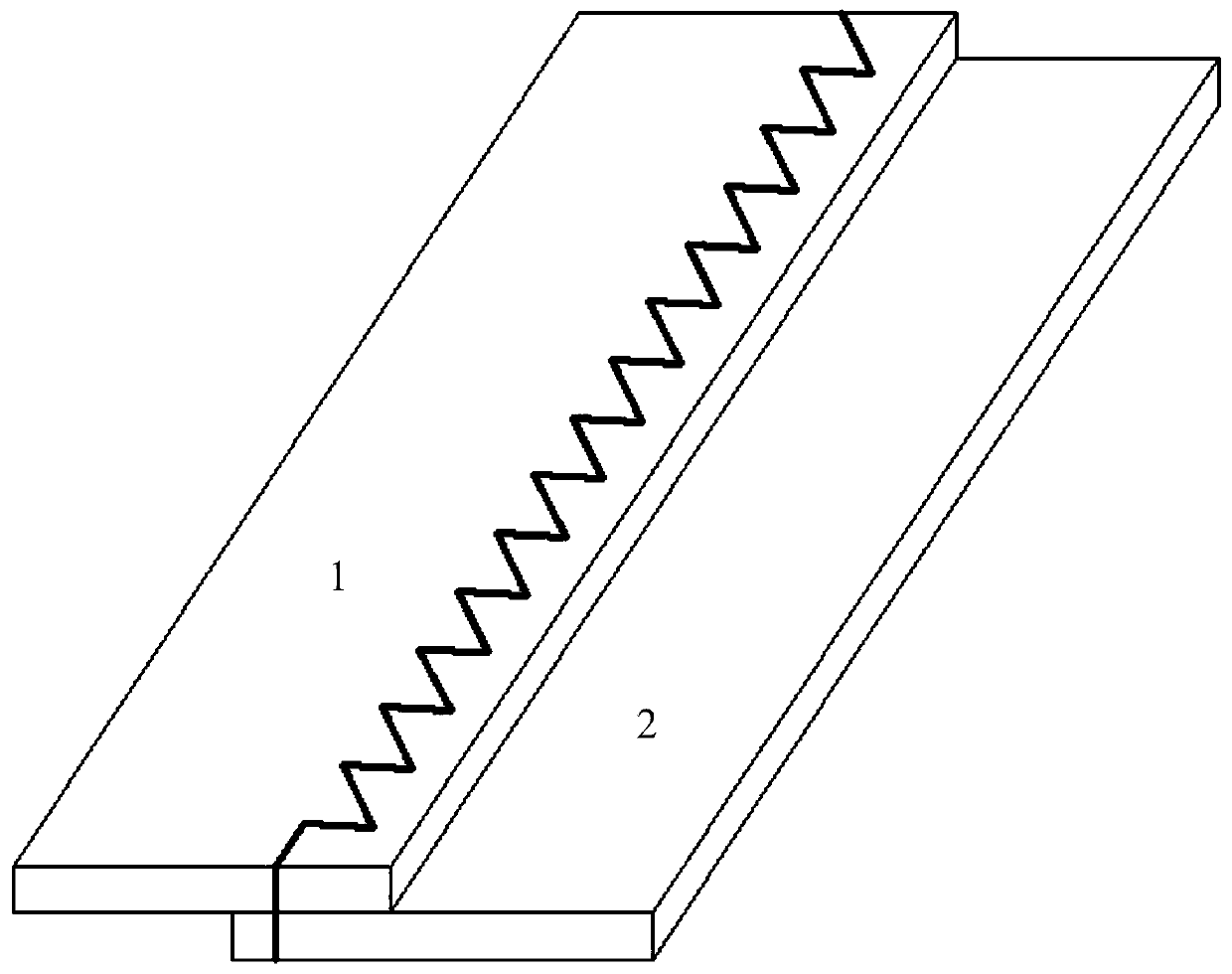

[0032] (1) The titanium alloy substrate and the steel plate are stacked and overlapped, and a sawtooth structure corresponding to the engagement is formed on the titanium alloy substrate and the steel plate by sawtooth cutting in the overlapping area;

[0033] (2) connecting the titanium alloy substrate and the steel plate through a zigzag structure to obtain a composite plate;

[0034] (3) The composite plate obtained in the step (2) is welded by friction stir welding to obtain a titanium-steel dissimilar metal structure; the steel plate in the composite plate is positioned at the advancing side of the welding process, and the titanium alloy substrate in the composite plate Located on the return side of the soldering process.

[0035] In the present invention, the titanium alloy substrate and the steel plate are stacked and overlapped, and a saw...

Embodiment 1

[0058] Using AISI 4340 steel plate and TC4 titanium alloy plate, first cut the TC4 titanium alloy and AISI 4340 steel into 180×60×2mm samples.

[0059] Then take the AISI 4340 steel plate sample and the TC4 titanium alloy plate sample respectively, according to figure 1 As shown, the edges of the two test plates are closely lapped together and fixed. In order to ensure that the sawtooth meshing structure is completely located in the lap area, the width of the lap area is set to be higher than the height of the saw teeth. Here, the width of the lap area is 8mm, and then start at 2mm from the outer edge of the overlapping area, and conduct wire EDM along its length.

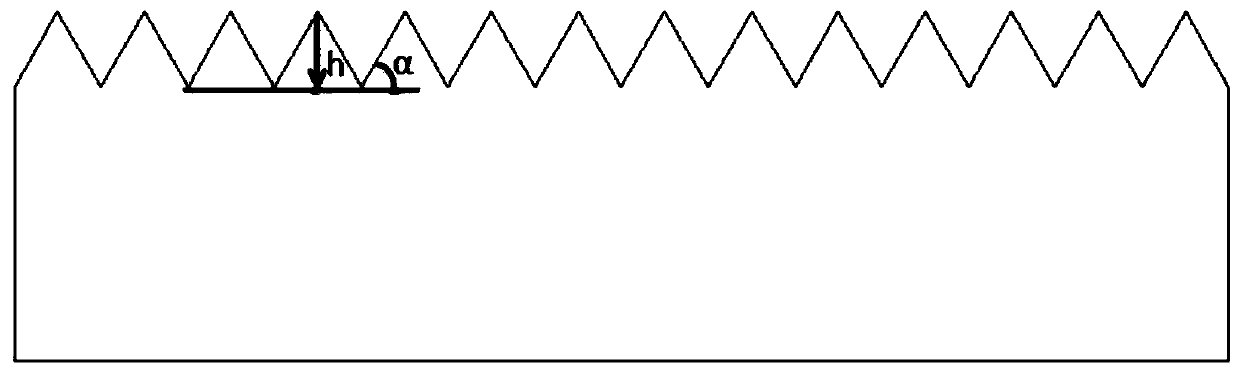

[0060] During the cutting process, an electric spark cutting program is set to form a corresponding meshing triangular sawtooth structure on the AISI 4340 steel plate sample and the TC4 titanium alloy plate sample. The sawtooth structure on one of the samples is as follows figure 2 As shown, the sawtooth height h...

Embodiment 2

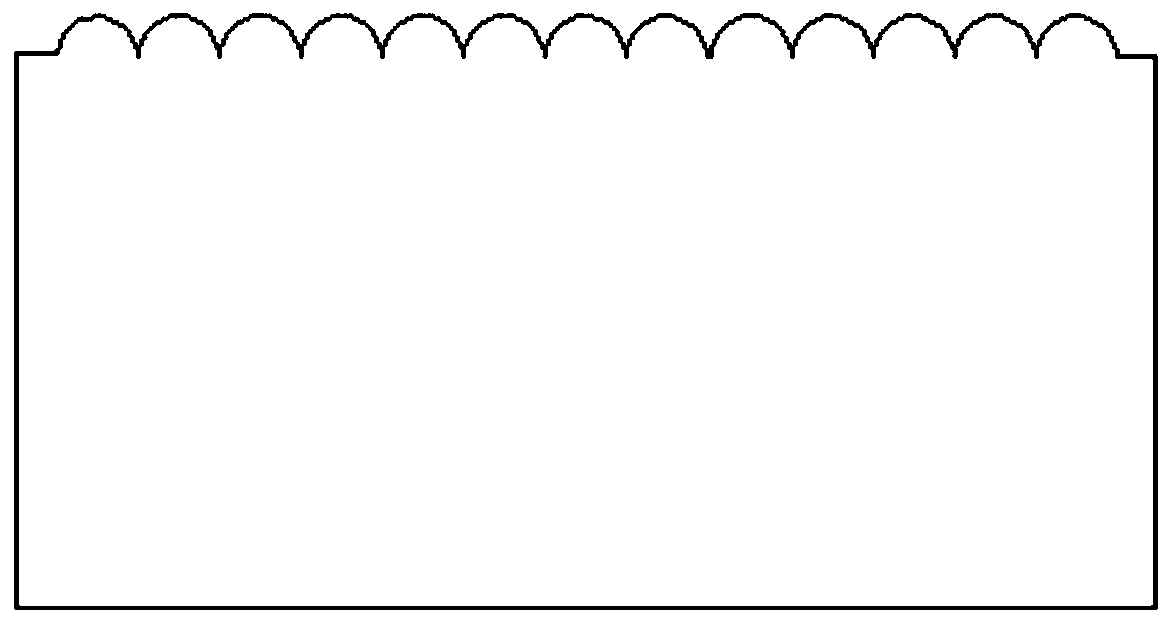

[0064] The titanium-steel dissimilar metal structure was prepared according to the method of Example 1, except that the plates used were TC4 titanium alloy plate and AISI 4340 steel.

[0065] The corresponding arc-shaped sawtooth structure is obtained by wire electric discharge cutting, and the sawtooth structure on one of the steel plates is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com