Front Tiller with Depth Limiting Function

A micro-tiller, front-mounted technology, applied in the field of agricultural machinery, can solve the problems of high manufacturing difficulty, decreased work efficiency, reduced work efficiency, etc., and achieve the effects of reducing raw material and processing costs, reducing driving burden, and convenient and fast processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

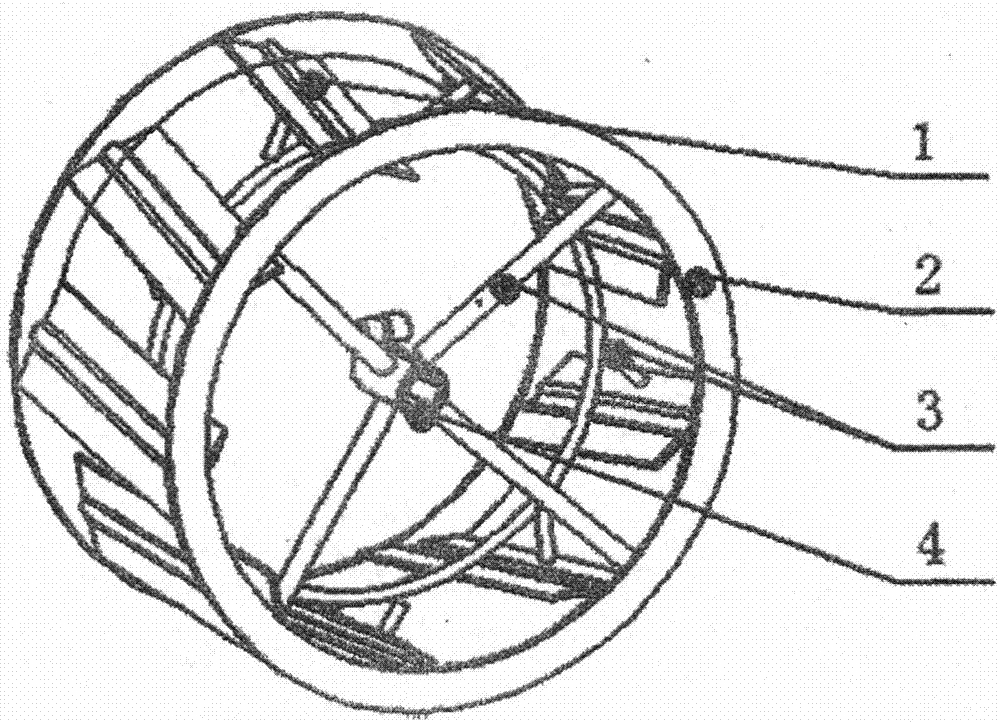

[0044] In the micro tillage machine with depth limiting function according to the embodiment of the present invention, the micro tillage machine includes:

[0045] A power unit (such as a diesel engine), a rotary tiller, and a handrail, and the rotary tiller is arranged at the head of the tiller, that is, a front-mounted tiller;

[0046] A transmission device, the transmission device is arranged between the power device and the rotary tiller;

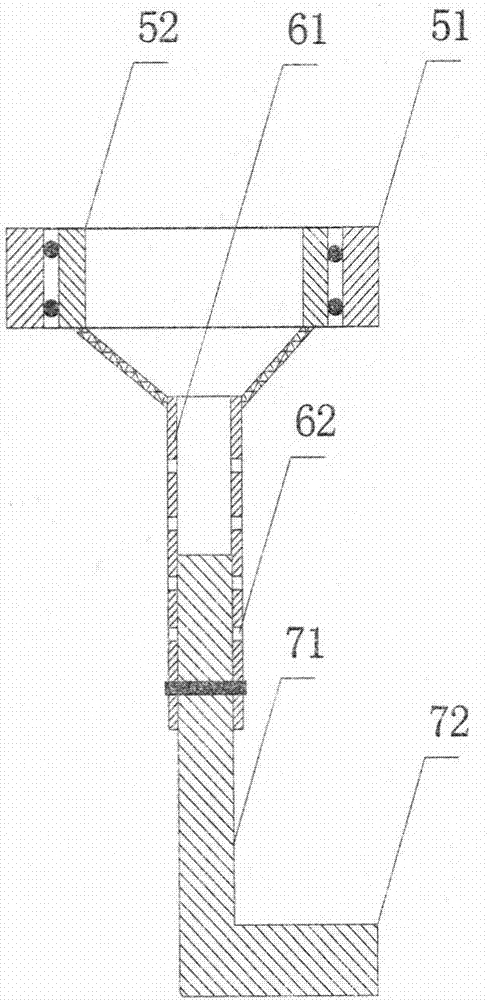

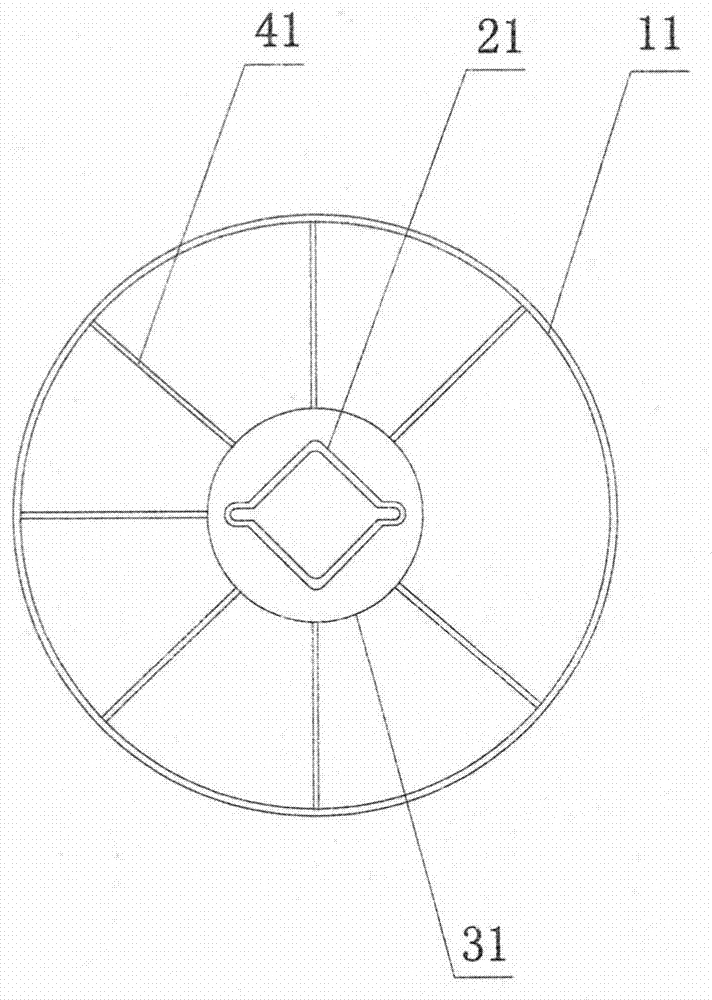

[0047] Rotating mechanism, described rotating mechanism is arranged on the bottom of described transmission device (as the fixing mount of fixed rotating mechanism); Described rotating mechanism can adopt parts such as bearing, and the outer ring 51 of bearing is fixed on the described transmission device, as figure 2 shown;

[0048] A support member, the support member is installed on the rotating mechanism; for example, the support member includes a horizontal part 72 and a vertical part 71, generally in an "L" shape, such as figu...

Embodiment 2

[0055] The micro-cultivator with depth-limiting function in this embodiment of the present invention is different from Embodiment 1 in that: the adjustment component adopts a hydraulic device, the support member is connected to the hydraulic device, and the power of the hydraulic device comes from a diesel engine.

Embodiment 3

[0057] The micro tillage machine with depth-limiting function in this embodiment of the present invention is different from Embodiment 1 in that: a blind hole is provided at the bottom of the transmission device, and one end of the tubular part is snapped into the blind hole, and one end of the tubular part is placed in the blind hole. It can rotate freely in the blind hole without breaking away from the blind hole, thereby replacing the bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com