A nanometer metal cleaning device with integrated functions of crushing and stirring

A nano-metal and cleaning device technology, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of high deposition speed, agglomeration, difficult substances, etc. Improved cleaning efficiency and high turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

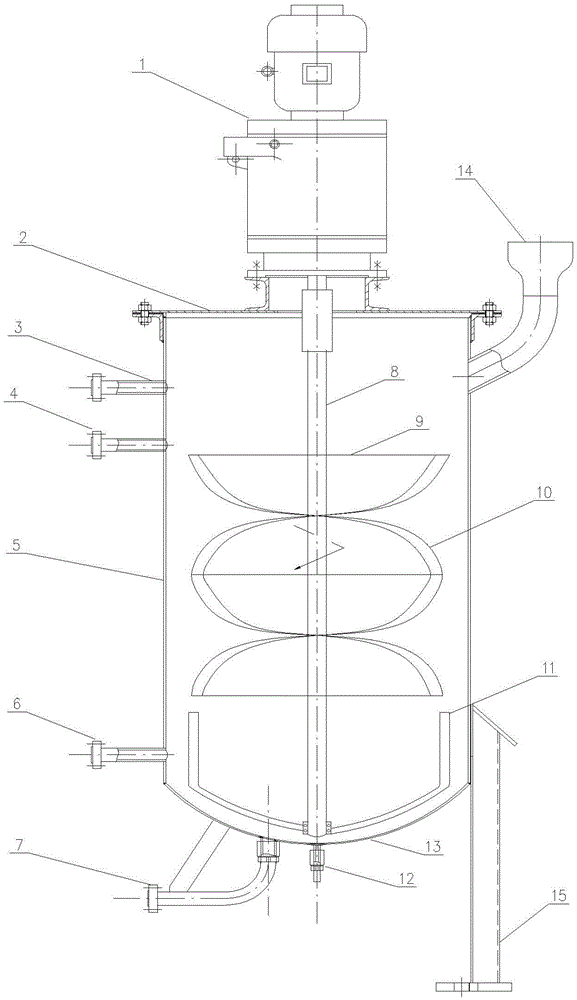

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] see figure 1 , a nanometer metal cleaning device with crushing and stirring integration functions of the present invention, comprising a motor 1, an end cover 2, a cleaning agent inlet 3, a liquid level gauge upper end interface 4, a cylinder body 5, a liquid level gauge lower end interface 6, and a discharge port 7. Rotating shaft 8, ribbon agitator, scraper 11, sewage outlet 12, conical head 13, feed inlet 14 and leg support 15.

[0025] Wherein, the end cap 2 is arranged on the top of the cylinder 5, the conical head 13 is arranged on the bottom of the cylinder 5, the discharge port 7 and the sewage outlet 12 are arranged on the bottom of the conical head 13, and the sewage outlet 12 is arranged on the bottom of the cylinder 5. At the center position of the bottom of the conical head 13, the discharge port 7 is set at an of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com