Fuel rail assembly of gasoline engine

A gasoline engine oil and assembly technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as high consistency requirements, injector clogging risk, etc., to achieve improved atomization effect, enhanced turbulence intensity, The effect of increased jet speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

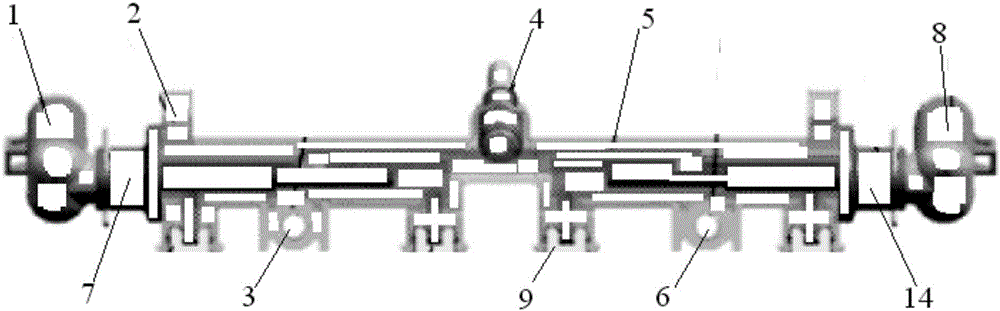

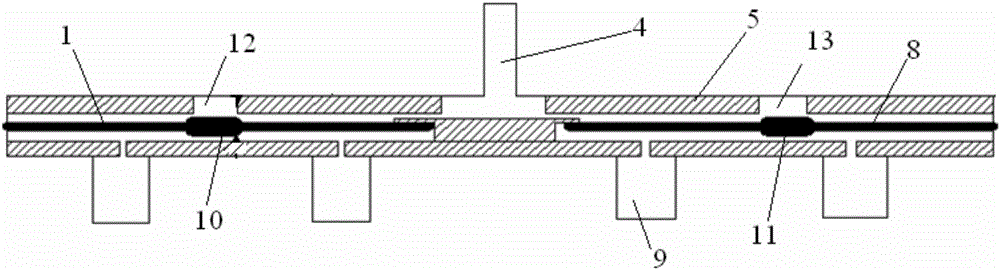

[0028] Such as figure 1 , figure 2 The structure of the present invention shown is a gasoline engine oil rail assembly, including an oil inlet 4, an oil passage 12, and an oil passage 13.

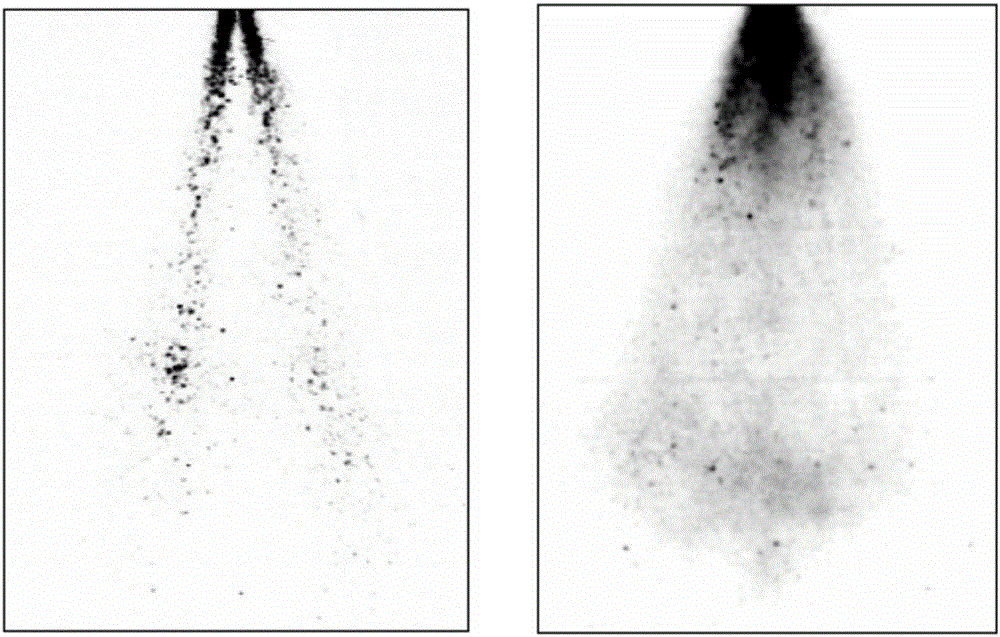

[0029] According to the dynamic crushing theory, when the cylindrical jet is ejected from the nozzle hole at high speed, under the combined action of fluid dynamics and ambient gas dynamics, the primary atomization is carried out first, and the continuous liquid column is split into liquid sheets and large droplets, and then the secondary atomization is carried out. Level atomization, gradually broken into a large number of fine droplets. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com