Tool for solving difficult stripping of live feed of large-scale steel casting mould

A technology for steel castings and moulds, which is applied in the field of tools for solving large-scale steel castings and molds that are difficult to remove from the mold. It can solve problems such as difficulties, labor, and large friction, and achieve the effect of reducing the time for moulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

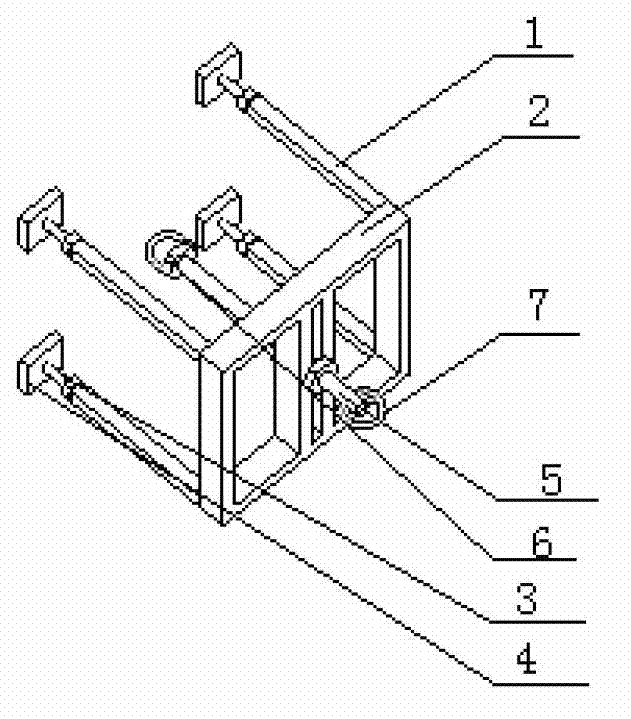

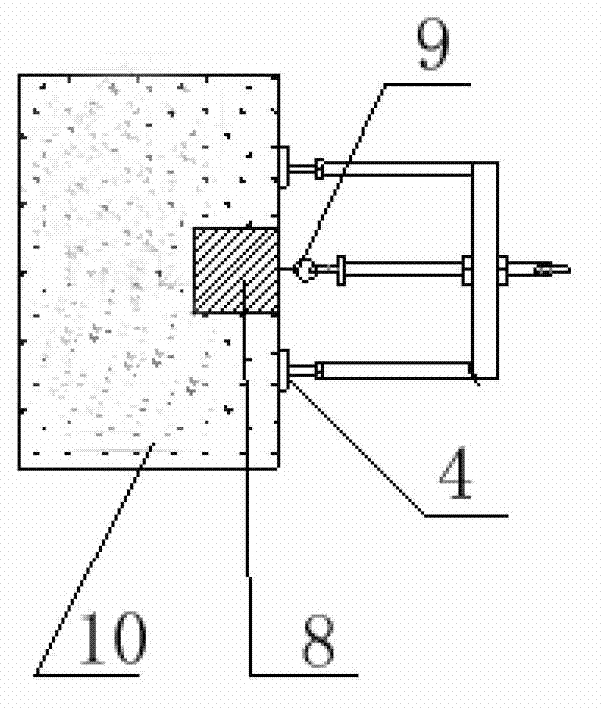

[0017] A tool used to solve the difficulty of mold loosening of large steel casting molds, such as figure 1 As shown: it includes a main frame 2 with a column 1, the end of each column 1 is connected with a screw 3 fitted with a nut, the screw 3 is fixed with a parallel iron 4, and the middle part of the main frame 2 is fixed by a nut. Telescopic threaded screw rod 5, threaded screw rod 5 is equipped with the nut that is fixed with hook 6 at the same end with above-mentioned pad iron 4, and the other end is fixed with handle 7.

[0018] The surface of the horn 4 is covered with rubber, which has the function of height adjustment.

[0019] The main frame 2 is polygonal, and the column 1 is connected to the intersection point of each two sides.

[0020] The main frame 2 is circular, and the four endpoints of its diameter intersecting at right angles are connected with the columns 1 .

[0021] The main frame 2 is elliptical, and the four endpoints of its major and minor axes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com